Grading systems assess and quantify academic performance to provide clear feedback on student progress and achievements. Different methods like numerical scores, letter grades, or pass/fail evaluations help standardize results across educational institutions. Discover how effective grading can enhance Your learning experience by exploring the rest of this article.

Table of Comparison

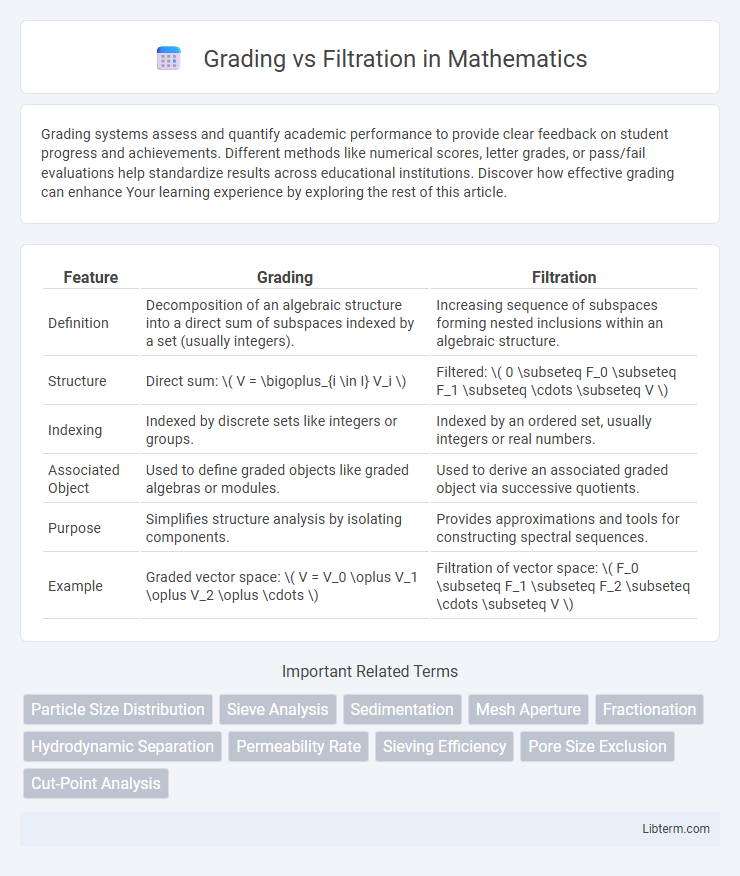

| Feature | Grading | Filtration |

|---|---|---|

| Definition | Decomposition of an algebraic structure into a direct sum of subspaces indexed by a set (usually integers). | Increasing sequence of subspaces forming nested inclusions within an algebraic structure. |

| Structure | Direct sum: \( V = \bigoplus_{i \in I} V_i \) | Filtered: \( 0 \subseteq F_0 \subseteq F_1 \subseteq \cdots \subseteq V \) |

| Indexing | Indexed by discrete sets like integers or groups. | Indexed by an ordered set, usually integers or real numbers. |

| Associated Object | Used to define graded objects like graded algebras or modules. | Used to derive an associated graded object via successive quotients. |

| Purpose | Simplifies structure analysis by isolating components. | Provides approximations and tools for constructing spectral sequences. |

| Example | Graded vector space: \( V = V_0 \oplus V_1 \oplus V_2 \oplus \cdots \) | Filtration of vector space: \( F_0 \subseteq F_1 \subseteq F_2 \subseteq \cdots \subseteq V \) |

Understanding Grading and Filtration: Key Differences

Grading involves sorting particles by size to improve soil structure and stability, commonly used in construction and landscaping projects to ensure proper drainage and load-bearing capacity. Filtration refers to the process of removing impurities or particles from fluids or air by passing them through a medium, crucial in water treatment, air purification, and industrial applications. Understanding these key differences helps optimize soil management practices versus fluid or air purification techniques in environmental and engineering contexts.

What Is Grading? Definition and Core Principles

Grading is the process of adjusting particle size distribution in soils to achieve desired engineering properties such as stability, permeability, and compaction. It involves the deliberate control of soil particle sizes, ranging from gravel to sand to fines, to enhance load-bearing capacity and drainage characteristics. Core principles of grading include uniformity coefficient, coefficient of gradation, and particle shape, all essential in classifying soil suitability for construction and infrastructure projects.

What Is Filtration? Definition and Core Principles

Filtration is a mechanical or physical process that separates solids from liquids or gases by passing the mixture through a porous medium or filter. Core principles include particle size exclusion, where particles larger than the filter pores are retained, and the use of pressure differences to drive the fluid through the filter medium. This method is essential in industries such as water treatment, pharmaceuticals, and chemical processing for purification and separation.

Applications of Grading in Industry

Grading plays a crucial role in industries such as construction, agriculture, and manufacturing by classifying materials based on particle size, shape, and distribution to ensure consistent quality and performance. In construction, grading ensures proper soil stability and drainage for foundations and roadbeds, while in agriculture, it optimizes soil texture for crop growth. Manufacturing processes rely on grading for quality control of raw materials like minerals, aggregates, and powders, enhancing product durability and efficiency.

Applications of Filtration in Industry

Filtration plays a critical role in various industrial applications, effectively removing particles and contaminants from liquids and gases to ensure product purity and process efficiency. Industries such as pharmaceuticals, food and beverage, water treatment, chemical manufacturing, and oil refining rely on advanced filtration systems to meet regulatory standards and protect equipment from damage. Techniques like microfiltration, ultrafiltration, and membrane filtration enable precise separation of solids from fluids, optimizing product quality and operational sustainability.

Essential Equipment for Grading Processes

Essential equipment for grading processes includes precision sieves, vibratory sifter machines, and automated sorting systems designed to ensure consistent particle size distribution. High-quality grading tools like rotary sifters and optical sorters enhance accuracy by separating materials based on size, shape, and density. Proper calibration and maintenance of grading equipment are critical to achieving reliable results in industries such as pharmaceuticals, food processing, and construction.

Essential Equipment for Filtration Processes

Essential equipment for filtration processes includes filter presses, vacuum filters, rotary drum filters, and cartridge filters, each designed to separate solids from liquids efficiently. Grading equipment, such as sieves and screens, primarily categorizes particles by size but does not perform liquid-solid separation like filtration systems. Selecting the appropriate filtration equipment depends on factors such as particle size, flow rate, and the physical-chemical properties of the mixture to ensure optimal separation performance.

Advantages and Limitations of Grading

Grading offers precise particle size control, ensuring uniformity essential in industries like construction and pharmaceuticals, which enhances product quality and performance. Its advantages include improved material sorting efficiency and better control over downstream processes, though it can be limited by equipment cost, slower processing speeds, and potential particle damage in fragile materials. Limitations include challenges in handling moist or sticky materials, requirement of frequent maintenance, and reduced effectiveness with extremely fine or coarse particles.

Advantages and Limitations of Filtration

Filtration offers the advantage of effectively removing fine particles, impurities, and contaminants from liquids or gases, ensuring higher purity and quality in various industrial and laboratory processes. However, its limitations include the potential for filter clogging, which can reduce efficiency and require frequent maintenance or replacement. Additionally, filtration may not be suitable for separating fluids with very similar particle sizes or for processing large volumes quickly without specialized equipment.

Choosing Grading or Filtration: Factors to Consider

Choosing between grading and filtration depends on soil composition, project scale, and desired drainage efficiency. Grading is ideal for large areas with stable soil that requires slope adjustments to direct water flow, while filtration suits environments needing sediment control through physical barriers or media. Cost, maintenance requirements, and local regulations also influence the selection of the most effective water management technique.

Grading Infographic

libterm.com

libterm.com