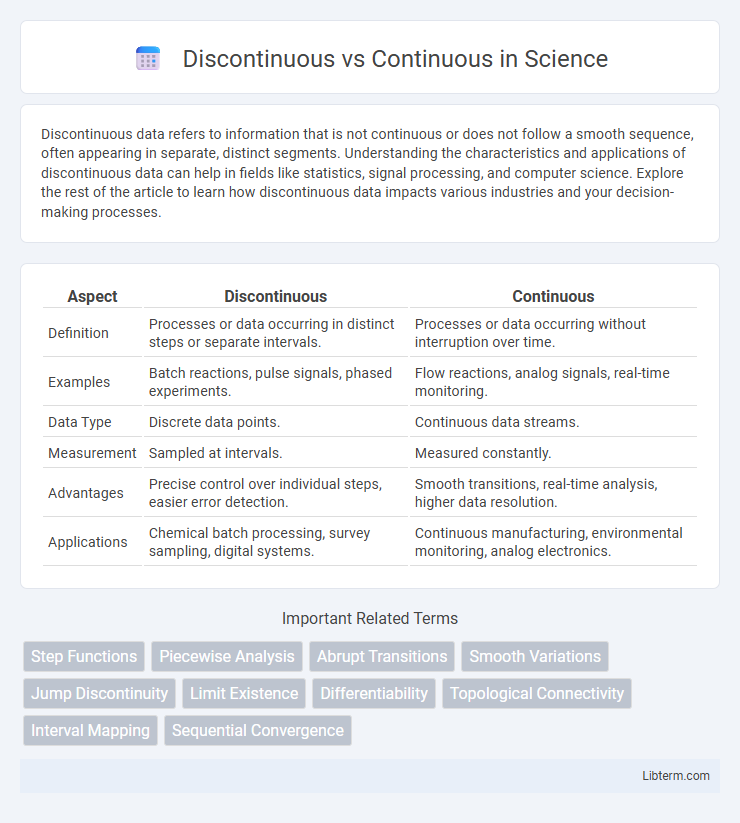

Discontinuous data refers to information that is not continuous or does not follow a smooth sequence, often appearing in separate, distinct segments. Understanding the characteristics and applications of discontinuous data can help in fields like statistics, signal processing, and computer science. Explore the rest of the article to learn how discontinuous data impacts various industries and your decision-making processes.

Table of Comparison

| Aspect | Discontinuous | Continuous |

|---|---|---|

| Definition | Processes or data occurring in distinct steps or separate intervals. | Processes or data occurring without interruption over time. |

| Examples | Batch reactions, pulse signals, phased experiments. | Flow reactions, analog signals, real-time monitoring. |

| Data Type | Discrete data points. | Continuous data streams. |

| Measurement | Sampled at intervals. | Measured constantly. |

| Advantages | Precise control over individual steps, easier error detection. | Smooth transitions, real-time analysis, higher data resolution. |

| Applications | Chemical batch processing, survey sampling, digital systems. | Continuous manufacturing, environmental monitoring, analog electronics. |

Introduction to Discontinuous and Continuous Systems

Discontinuous systems exhibit abrupt changes in state or behavior at specific points, often modeled using differential equations with impulses or switching conditions. Continuous systems change smoothly over time, described by continuous differential equations that reflect gradual state evolution. Understanding the distinction between these system types is crucial for accurately modeling dynamic processes in control theory, signal processing, and engineering applications.

Key Differences Between Discontinuous and Continuous

Discontinuous data consists of distinct, separate values, often represented by integers or categories, while continuous data includes any value within a range, such as measurements. Key differences include the nature of data points; continuous data can take infinite possible values between two points, whereas discontinuous data values are finite and countable. In statistical analysis, continuous data allows for more complex calculations like means and standard deviations, whereas discontinuous data often requires frequency counts or mode analysis.

Advantages of Continuous Processes

Continuous processes offer enhanced efficiency by maintaining constant operation schedules that reduce downtime and increase production rates. These processes ensure consistent product quality through steady-state conditions, minimizing variability and defects. Continuous manufacturing also enables better scalability and integration with automated systems, lowering operational costs and improving resource utilization.

Benefits of Discontinuous Methods

Discontinuous methods offer enhanced flexibility in handling complex geometries and allow for local mesh refinement without impacting the global solution, resulting in improved accuracy. These methods facilitate easier parallelization due to their element-wise formulation, which reduces inter-element dependency and computational communication overhead. Furthermore, discontinuous techniques provide better stability properties for convection-dominated problems, making them ideal for high-order numerical simulations.

Common Applications of Discontinuous Approaches

Discontinuous approaches are commonly applied in fields such as computational fluid dynamics for simulating complex flow patterns and fracture mechanics in materials science where abrupt changes occur. These methods excel in modeling phenomena with sharp interfaces or discontinuities, like shock waves or crack propagation, providing higher accuracy than continuous methods. Industries including aerospace, civil engineering, and geotechnical analysis benefit significantly from the precision of discontinuous modeling techniques.

Typical Uses of Continuous Processes

Continuous processes are commonly used in industries requiring large-scale production with consistent output, such as chemical manufacturing, oil refining, and food processing. These processes enable uninterrupted operation, enhancing efficiency and product uniformity while reducing downtime and labor costs. Continuous systems are ideal for producing materials like plastics, pharmaceuticals, and beverages where maintaining steady conditions is crucial for quality control.

Efficiency Comparison: Discontinuous vs Continuous

Discontinuous processes often exhibit lower overall efficiency due to frequent start-stop cycles that cause energy losses and increased downtime, whereas continuous processes maintain steady-state operations that optimize energy consumption and throughput. Continuous operations benefit from consistent heat and mass transfer, reducing variability and improving product quality, which enhances operational efficiency compared to batch processing. Industrial sectors prioritize continuous methods for large-scale production to maximize efficiency, though discontinuous processes remain valuable for flexibility and customization.

Challenges in Discontinuous and Continuous Systems

Discontinuous systems face challenges such as handling abrupt changes, instability, and complex switching dynamics that complicate modeling and control design. Continuous systems struggle with maintaining stability over infinite time horizons and managing nonlinearities inherent in real-world processes. Both systems require advanced mathematical tools like hybrid system theory and robust control techniques to address their specific dynamic behavior effectively.

Choosing the Right Approach: Factors to Consider

Selecting between discontinuous and continuous approaches depends heavily on project scope, timelines, and resource availability. Continuous methods often suit dynamic environments requiring ongoing monitoring, while discontinuous strategies fit projects with clearly defined phases and resource constraints. Evaluating stakeholder needs, data variability, and operational flexibility guides the choice for optimal process efficiency.

Future Trends in Discontinuous and Continuous Technologies

Future trends in discontinuous technologies emphasize breakthroughs in quantum computing and autonomous robotics, driving transformative changes in sectors like healthcare and manufacturing. Continuous technologies advance with the integration of AI-powered automation and IoT connectivity, enhancing real-time data processing and seamless system interoperability. Both technology types converge to enable hybrid models that optimize efficiency and innovation across smart cities and Industry 4.0 frameworks.

Discontinuous Infographic

libterm.com

libterm.com