Mechanical systems play a crucial role in powering industries and everyday machinery, converting energy into motion and performing essential tasks with precision. Advances in mechanical engineering have led to more efficient, durable, and innovative designs that optimize performance and reduce operational costs. Discover how these mechanical innovations can impact your projects by exploring the rest of the article.

Table of Comparison

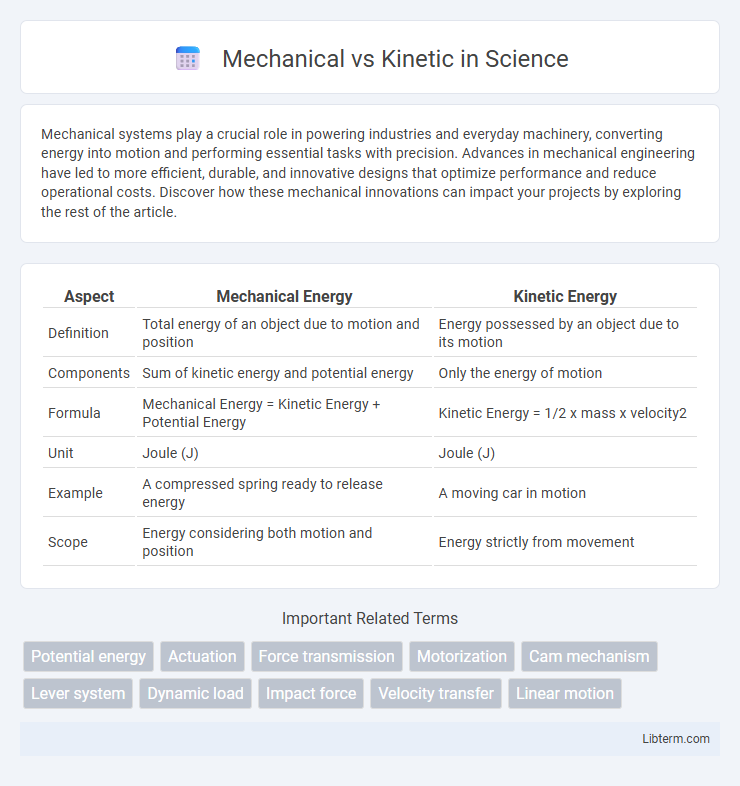

| Aspect | Mechanical Energy | Kinetic Energy |

|---|---|---|

| Definition | Total energy of an object due to motion and position | Energy possessed by an object due to its motion |

| Components | Sum of kinetic energy and potential energy | Only the energy of motion |

| Formula | Mechanical Energy = Kinetic Energy + Potential Energy | Kinetic Energy = 1/2 x mass x velocity2 |

| Unit | Joule (J) | Joule (J) |

| Example | A compressed spring ready to release energy | A moving car in motion |

| Scope | Energy considering both motion and position | Energy strictly from movement |

Introduction to Mechanical and Kinetic Concepts

Mechanical energy encompasses both potential and kinetic energy, representing the total energy stored in and possessed by an object due to its position or motion. Kinetic energy specifically refers to the energy an object has because of its velocity, calculated as half the mass times the square of its speed (KE = 1/2 mv2). Understanding the distinction between mechanical and kinetic energy is fundamental in physics, as mechanical energy offers a broader concept including energy stored in an object's configuration, while kinetic energy strictly relates to motion.

Defining Mechanical Energy

Mechanical energy is the sum of kinetic energy, which is the energy of motion, and potential energy, the stored energy based on position. It quantifies the total energy possessed by an object due to its movement and spatial configuration. Mechanical energy plays a critical role in systems ranging from simple machines to complex physical phenomena.

Understanding Kinetic Energy

Kinetic energy is the energy an object possesses due to its motion, calculated as half the product of its mass and the square of its velocity (KE = 1/2 mv2). Unlike mechanical energy, which includes both kinetic and potential energy, kinetic energy specifically quantifies the energy associated with an object's movement. Understanding kinetic energy is essential for analyzing dynamic systems in physics and engineering, where motion and force interactions determine system behavior.

Key Differences: Mechanical vs Kinetic

Mechanical energy is the sum of potential and kinetic energy in an object, representing the total energy due to its position and motion. Kinetic energy specifically refers to the energy an object possesses because of its movement, calculated as half the mass times velocity squared. Key differences lie in that mechanical energy encompasses both stored (potential) and active (kinetic) energy, while kinetic energy exclusively measures the energy in motion.

Mechanical Energy in Real-World Applications

Mechanical energy, the sum of potential and kinetic energy, plays a crucial role in engineering applications such as engines, turbines, and elevators, where it is transformed and harnessed for work. In renewable energy systems like wind turbines and hydroelectric dams, mechanical energy derived from motion or stored forces is converted into electrical power, demonstrating its practical importance. Understanding the interplay between mechanical and kinetic energy enables optimized design and efficiency in machines and structures across various industries.

Kinetic Energy in Everyday Life

Kinetic energy, the energy possessed by an object in motion, plays a crucial role in everyday life by powering activities such as walking, driving, and the operation of machinery. This form of energy depends on both the mass and velocity of moving objects, making it essential in understanding how forces translate into movement and work. Examples include the energy transferred by a rolling ball, the movement of wind turbines, and the flow of water in hydroelectric plants, all harnessing kinetic energy to perform useful tasks.

Mechanical Systems: Advantages and Limitations

Mechanical systems offer robust performance with high durability and efficiency in converting energy into motion, making them ideal for heavy-duty applications. Their simple design ensures ease of maintenance and reliability, reducing downtime in industrial settings. However, mechanical systems face limitations such as increased wear and tear, noise production, and less adaptability compared to electronic or kinetic alternatives.

Kinetic Systems: Pros and Cons

Kinetic systems harness motion energy, offering advantages such as increased efficiency and continuous power generation without the need for external fuel sources. However, they often face challenges like mechanical wear, complex maintenance requirements, and limited energy storage capacity. Despite these drawbacks, kinetic systems are valuable in renewable energy applications, providing sustainable solutions with reduced environmental impact.

How Mechanical and Kinetic Energies Interact

Mechanical energy is the sum of kinetic and potential energies within a system, where kinetic energy represents motion and mechanical energy accounts for position and movement combined. During interactions, mechanical energy transfers between kinetic and potential forms, such as when a pendulum swings--kinetic energy converts to potential energy at the apex and back to kinetic energy at the lowest point. This energy interchange underpins many mechanical processes, governed by conservation laws that dictate how energy transforms without loss in ideal systems.

Choosing Between Mechanical and Kinetic Solutions

Choosing between mechanical and kinetic solutions depends on the specific application requirements, such as energy efficiency, durability, and maintenance needs. Mechanical systems typically offer precise control and reliability in static or slower-moving applications, while kinetic systems excel in scenarios involving dynamic motion and energy transfer. Evaluating factors like load capacity, operational environment, and cost-effectiveness ensures optimal selection between mechanical and kinetic solutions.

Mechanical Infographic

libterm.com

libterm.com