Laminar flow refers to the smooth, orderly movement of fluid particles in parallel layers, with minimal mixing and disruption between them. This behavior is crucial in applications requiring predictable fluid dynamics and reduced friction, such as in aerodynamic design and medical devices. Discover how laminar flow impacts your projects by exploring the detailed explanations ahead.

Table of Comparison

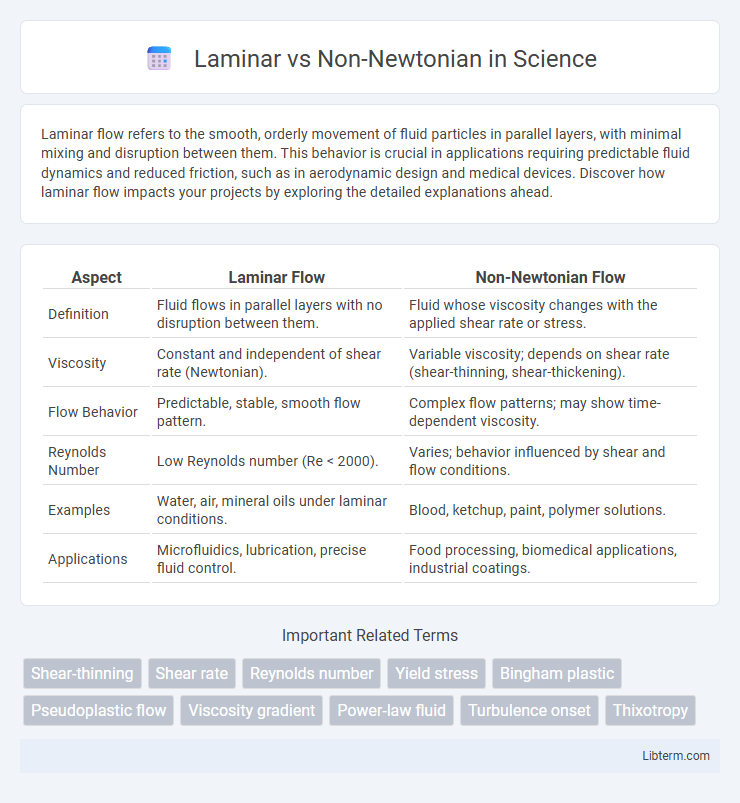

| Aspect | Laminar Flow | Non-Newtonian Flow |

|---|---|---|

| Definition | Fluid flows in parallel layers with no disruption between them. | Fluid whose viscosity changes with the applied shear rate or stress. |

| Viscosity | Constant and independent of shear rate (Newtonian). | Variable viscosity; depends on shear rate (shear-thinning, shear-thickening). |

| Flow Behavior | Predictable, stable, smooth flow pattern. | Complex flow patterns; may show time-dependent viscosity. |

| Reynolds Number | Low Reynolds number (Re < 2000). | Varies; behavior influenced by shear and flow conditions. |

| Examples | Water, air, mineral oils under laminar conditions. | Blood, ketchup, paint, polymer solutions. |

| Applications | Microfluidics, lubrication, precise fluid control. | Food processing, biomedical applications, industrial coatings. |

Understanding Laminar Flow

Laminar flow is characterized by smooth, orderly fluid motion where layers slide past one another without mixing, typically occurring at low Reynolds numbers below 2,000. In contrast, Non-Newtonian fluids exhibit variable viscosity depending on shear rate, which influences whether the flow remains laminar or transitions to turbulent. Understanding laminar flow in Non-Newtonian fluids is crucial for accurate modeling in industries like biomedical engineering and polymer processing, where precise control over fluid dynamics impacts performance and product quality.

Defining Non-Newtonian Fluids

Non-Newtonian fluids exhibit flow behavior that deviates from Newton's law of viscosity, meaning their viscosity changes under applied stress or shear rate, unlike laminar flow in Newtonian fluids where viscosity remains constant. These fluids can display shear-thinning, shear-thickening, or viscoelastic characteristics, making their flow profiles more complex than the predictable, smooth layers seen in laminar flow. Understanding non-Newtonian fluid dynamics is essential in industries such as food processing, polymer manufacturing, and biomedical applications where precise control of flow behavior impacts product quality and performance.

Key Characteristics of Laminar Flow

Laminar flow is characterized by smooth, orderly fluid motion where layers glide past each other with minimal mixing, typically occurring at low Reynolds numbers below 2,000. In laminar flow, velocity profiles are parabolic, and shear stress is linearly related to the fluid's viscosity, which distinguishes it from the complex behavior seen in non-Newtonian fluids. This steady, predictable flow pattern contrasts with the turbulence and variable viscosity-dependent behavior of non-Newtonian fluids under similar conditions.

Types of Non-Newtonian Behaviors

Non-Newtonian fluids exhibit unique flow behaviors that differ significantly from laminar flows in Newtonian fluids, primarily due to their variable viscosity under different stress conditions. Types of non-Newtonian behaviors include shear-thinning (pseudoplastic), shear-thickening (dilatant), Bingham plastic, and thixotropic fluids, each characterized by distinct stress-strain relationships and time-dependent viscosity changes. Understanding these behaviors is crucial for applications in industries such as polymer processing, food manufacturing, and biomedical engineering where fluid dynamics influence product performance and process efficiency.

Viscosity Differences: Laminar vs Non-Newtonian

Laminar flow exhibits a constant viscosity where the fluid layers move smoothly in parallel, maintaining a predictable relationship between shear stress and shear rate. Non-Newtonian fluids display variable viscosity that changes with shear rate or time, leading to complex flow behaviors such as shear-thinning, shear-thickening, or viscoelasticity. Understanding these viscosity differences is crucial for engineering applications involving fluid dynamics, as laminar flow assumes Newtonian properties while non-Newtonian fluids require specialized modeling approaches.

Flow Behavior in Pipes and Channels

Laminar flow in pipes and channels features smooth, orderly fluid motion characterized by parallel layers with minimal mixing, typically occurring at low Reynolds numbers below 2000. Non-Newtonian fluids exhibit variable viscosity dependent on shear rate, causing complex flow behaviors that deviate from the linear velocity profile seen in Newtonian laminar flow, often resulting in shear-thinning or shear-thickening effects. Understanding the interaction between laminar flow regimes and non-Newtonian fluid properties is crucial for accurate prediction of pressure drops, flow rates, and heat transfer in industrial piping systems.

Practical Applications in Industry

Laminar flow in Non-Newtonian fluids is critical for precise control in industries such as food processing and polymer manufacturing, where shear-dependent viscosity affects mixing and pumping efficiency. Practical applications include coating processes, where maintaining laminar flow ensures uniform film thickness and surface quality. Understanding the transition between laminar and turbulent flow in Non-Newtonian fluids enhances design optimization for chemical reactors and biomedical devices.

Measurement Techniques for Flow Types

Measurement techniques for laminar and non-Newtonian flow types often involve rheometers and viscometers to accurately characterize flow behavior under varying shear rates. Particle image velocimetry (PIV) and laser Doppler anemometry (LDA) enable precise velocity profile measurements crucial for distinguishing laminar flow patterns from complex, shear-dependent non-Newtonian fluids. Pressure drop analysis and flow visualization methods complement these techniques by providing insights into fluid mechanics in pipelines and microchannels, enhancing the reliability of flow type determination.

Advantages and Limitations

Laminar flow in Non-Newtonian fluids ensures predictable and stable fluid behavior, facilitating precise control in processes like polymer extrusion and biomedical applications. The primary advantage lies in minimizing flow disturbances and shear rate variations, which enhances accuracy in viscosity measurements and reduces energy consumption. However, limitations include sensitivity to changes in fluid properties and flow conditions, making laminar flow harder to maintain in complex industrial systems where Non-Newtonian fluids may exhibit unpredictable shear-thinning or shear-thickening behavior.

Future Research and Emerging Technologies

Future research in laminar and non-Newtonian fluid dynamics is advancing through the integration of machine learning algorithms and high-fidelity simulations to accurately predict flow behaviors under complex conditions. Emerging technologies such as microfluidic devices and smart materials are enabling precise manipulation of non-Newtonian fluids in biomedical and industrial applications. Continued development in real-time rheological measurement tools promises enhanced understanding and control of laminar flow characteristics in non-Newtonian systems.

Laminar Infographic

libterm.com

libterm.com