A reboiler provides the necessary heat to the bottom of a distillation column, causing the liquid mixture to vaporize and separate based on boiling points. A condenser cools the vapor at the top of the column, turning it back into liquid to be collected or refluxed, ensuring efficient separation. Discover how optimizing your reboiler and condenser can enhance process performance by reading the rest of the article.

Table of Comparison

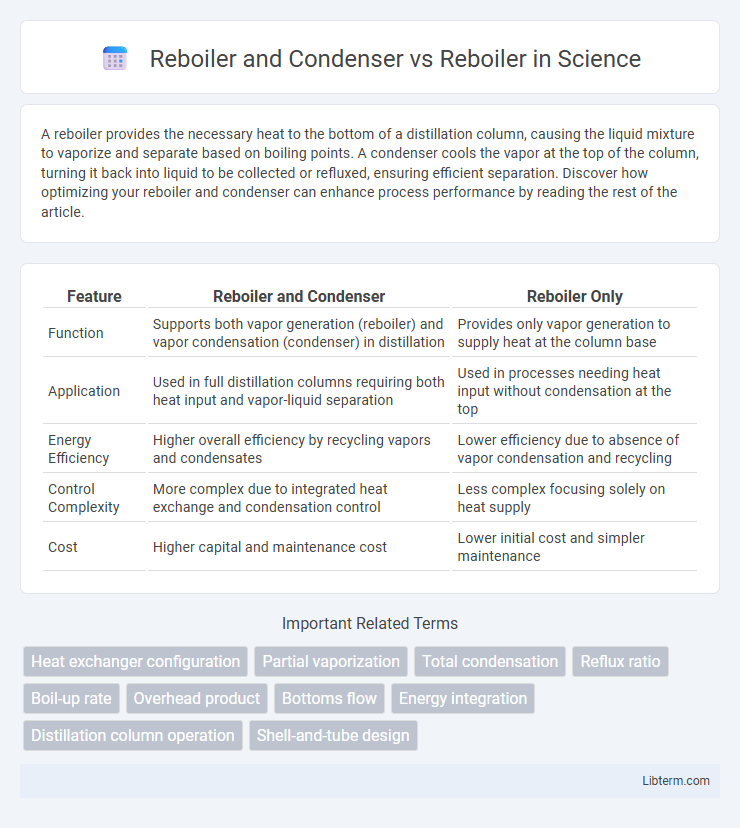

| Feature | Reboiler and Condenser | Reboiler Only |

|---|---|---|

| Function | Supports both vapor generation (reboiler) and vapor condensation (condenser) in distillation | Provides only vapor generation to supply heat at the column base |

| Application | Used in full distillation columns requiring both heat input and vapor-liquid separation | Used in processes needing heat input without condensation at the top |

| Energy Efficiency | Higher overall efficiency by recycling vapors and condensates | Lower efficiency due to absence of vapor condensation and recycling |

| Control Complexity | More complex due to integrated heat exchange and condensation control | Less complex focusing solely on heat supply |

| Cost | Higher capital and maintenance cost | Lower initial cost and simpler maintenance |

Introduction to Reboilers and Condensers

Reboilers and condensers are crucial heat transfer equipment used in distillation processes to facilitate phase changes; reboilers provide heat to vaporize the liquid at the bottom of the column, while condensers remove heat to condense vapor at the top. A reboiler maintains the vapor-liquid equilibrium by supplying the necessary boiling energy, significantly impacting separation efficiency and energy consumption. Condensers, by cooling and condensing vapors, control reflux ratio and maintain column pressure, directly influencing product purity and process stability.

Key Functions of Reboilers

Reboilers serve the crucial function of supplying heat to the bottom of distillation columns, facilitating the vaporization of the liquid mixture for component separation. Unlike condensers, which cool and condense vapor at the top of the column, reboilers maintain the necessary temperature and vapor flow to drive the separation process efficiently. Key functions of reboilers include transferring heat to generate vapor, controlling bottom product composition, and ensuring energy efficiency in distillation operations.

Understanding Condensers in Process Systems

Condensers play a critical role in process systems by removing heat from vapor streams, enabling phase change from vapor to liquid for efficient energy recovery and process control. In comparison to reboilers, which supply heat to liquid mixtures for vaporization, condensers focus on heat extraction and condensation, often enhancing separation and recycling of process fluids. Understanding condenser design and operation is essential to optimize heat integration, improve energy efficiency, and maintain stable operation in chemical processing units.

Reboiler and Condenser: Roles in Distillation Columns

Reboilers and condensers play critical roles in distillation columns by maintaining the necessary temperature gradients for efficient separation. The reboiler supplies heat to the bottom of the column, generating vapor that rises through the trays or packing, while the condenser cools and condenses the vapor at the top, allowing reflux to return liquid down the column. Together, these components optimize energy usage and enhance the purity of the separated components in continuous distillation processes.

Reboiler vs. Reboiler: Comparing Different Types

Different types of reboilers, such as kettle, thermosyphon, and forced circulation reboilers, exhibit distinct operational mechanisms impacting heat transfer efficiency and maintenance requirements. Kettle reboilers provide stable boiling conditions with lower fouling rates, while thermosyphon types rely on natural circulation to reduce mechanical components but may face limitations in high-viscosity fluids. Forced circulation reboilers enable precise control of liquid flow and temperature, ideal for processes requiring consistent thermal performance, contrasting with simpler designs focused mainly on robust reboiling in standard distillation columns.

Design Considerations for Reboilers

Reboiler design considerations focus on heat transfer efficiency, fluid compatibility, and minimizing fouling to ensure effective vaporization in distillation processes. Key parameters include selecting appropriate heat transfer surfaces, managing pressure drop, and ensuring thermal stress resilience to maintain operational reliability. In contrast to condensers, which primarily focus on maximizing condensation and heat recovery, reboilers emphasize boiling heat transfer and preventing dry-out conditions to sustain process stability.

Efficiency Differences: Reboiler with Condenser vs. Standalone Reboiler

A Reboiler paired with a Condenser enhances overall thermal efficiency by recovering and recycling vapor energy, reducing heat load and operational costs compared to a Standalone Reboiler. The combined system ensures better temperature control and minimizes energy wastage through condensate reflux, improving separation processes in distillation columns. Standalone Reboilers lack this integrated energy recovery, resulting in higher fuel consumption and less optimized heat utilization.

Operational Challenges: Reboiler and Condenser Integration

Reboiler and condenser integration presents operational challenges such as synchronized temperature control and efficient heat exchange management to maintain optimal distillation column performance. Imbalances in heat duties can lead to energy inefficiencies and potential flooding or weeping within the column, impacting separation quality. Effective integration requires precise instrumentation and real-time monitoring to address dynamic process changes and ensure stable operation.

Industrial Applications and Case Studies

Reboilers and condensers are critical components in industrial distillation columns, enhancing energy efficiency and process control by enabling precise vapor-liquid phase changes. Case studies in petrochemical plants reveal that integrated reboiler-condenser systems reduce energy consumption by up to 20% compared to standalone reboilers, optimizing separation performance and operational stability. Industrial applications in chemical manufacturing emphasize improved product purity and reduced environmental impact through advanced heat integration techniques combining reboilers and condensers.

Summary: Choosing the Right Equipment for Your Process

Selecting between a Reboiler and Condenser versus a standalone Reboiler depends on process requirements such as heat duty, phase changes, and operational efficiency. Reboiler and Condenser systems enable precise temperature control and improved energy integration in distillation columns, whereas standalone Reboilers primarily provide the necessary vaporization for separation. Optimal equipment choice hinges on factors like column design, energy costs, and desired product purity to maximize process performance and sustainability.

Reboiler and Condenser Infographic

libterm.com

libterm.com