A reboiler efficiently transfers heat to process fluids, generating vapor necessary for distillation and separation in industrial applications. Heaters, on the other hand, provide controlled thermal energy to maintain optimal temperatures in various chemical and manufacturing processes. Explore the rest of the article to understand how these critical components impact your system's performance and energy efficiency.

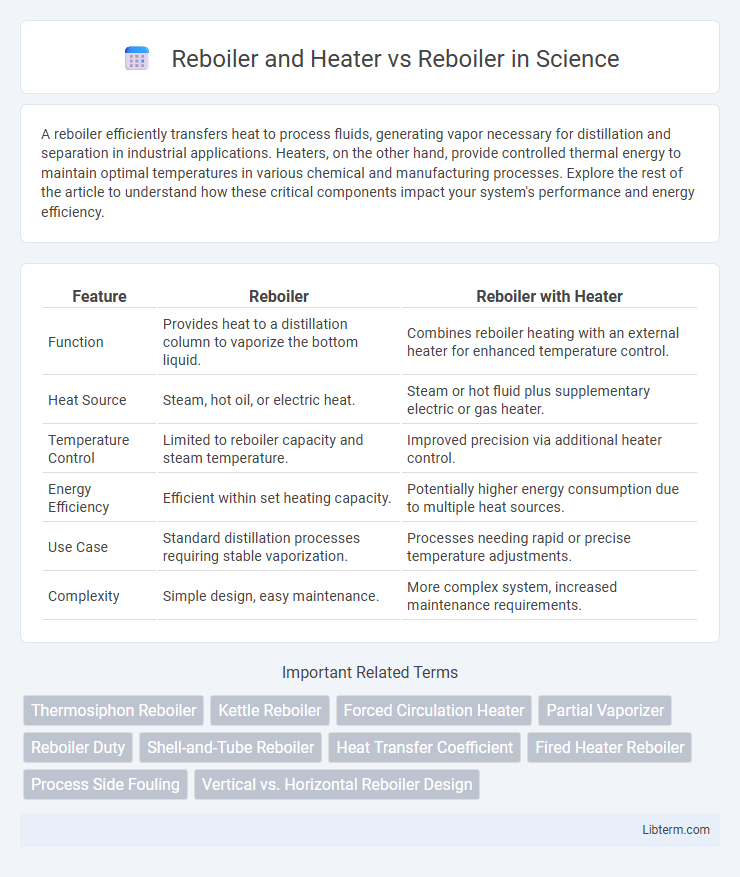

Table of Comparison

| Feature | Reboiler | Reboiler with Heater |

|---|---|---|

| Function | Provides heat to a distillation column to vaporize the bottom liquid. | Combines reboiler heating with an external heater for enhanced temperature control. |

| Heat Source | Steam, hot oil, or electric heat. | Steam or hot fluid plus supplementary electric or gas heater. |

| Temperature Control | Limited to reboiler capacity and steam temperature. | Improved precision via additional heater control. |

| Energy Efficiency | Efficient within set heating capacity. | Potentially higher energy consumption due to multiple heat sources. |

| Use Case | Standard distillation processes requiring stable vaporization. | Processes needing rapid or precise temperature adjustments. |

| Complexity | Simple design, easy maintenance. | More complex system, increased maintenance requirements. |

Introduction to Reboilers and Heaters

Reboilers and heaters are essential components in industrial processes to provide heat for phase separation and temperature control. A reboiler primarily supplies heat at the bottom of distillation columns to generate vapor, ensuring efficient separation of components. Heaters, however, serve broader thermal applications, including heating fluids or gases across various stages without necessarily inducing phase changes.

Defining the Reboiler-Heater Combination

The Reboiler-Heater combination integrates the functions of reheating and vaporizing process fluids within a single unit, enhancing energy efficiency in distillation systems. Unlike a standalone reboiler that solely supplies heat to vaporize the bottom liquid, the combination unit effectively maintains temperature control while optimizing heat transfer surface area. This dual-function design reduces footprint and operational costs by consolidating equipment and improving thermal energy utilization.

Standalone Reboiler: Function and Design

A standalone reboiler functions to supply the necessary heat to the bottom of a distillation column, converting the liquid mixture into vapor to facilitate component separation. It is designed with efficient heat transfer surfaces, such as shell-and-tube or thermosyphon types, optimized to handle specific thermal duty, pressure, and liquid properties independently from other heating units. Unlike integrated heater-reboiler systems, standalone reboilers operate solely as heat exchangers, enhancing operational flexibility and precise temperature control within process units.

Reboiler and Heater: Operational Differences

Reboilers and heaters serve to provide heat in chemical processes, but reboilers specifically supply vaporization heat to the bottom of distillation columns, maintaining separation efficiency. Heaters generally raise the temperature of fluids before entering a process, without directly affecting phase separation or vapor-liquid equilibrium. The operational difference centers on reboilers' role in vapor generation and column control, while heaters primarily provide temperature elevation.

Heat Source Options for Reboilers

Reboilers rely on various heat source options, including steam, hot oil, and electric heating, to efficiently vaporize the bottom liquid in distillation columns. Utilizing steam as a heat source offers rapid and uniform heat transfer, making it the most common choice for conventional reboilers, while electric reboilers provide precise temperature control and reduced fouling for specialized applications. Heater types integrated with reboilers, such as kettle reboilers and thermosyphon reboilers, optimize heat transfer based on the selected heat source, enhancing process efficiency and energy utilization.

Efficiency Comparison: Combined vs. Separate Units

Combined reboiler and heater units enhance thermal efficiency by integrating heat exchange processes, reducing energy losses typical in separate units. Separate reboiler and heater systems often face higher operational costs due to duplicated heat input and increased entropy generation. Optimizing combined units supports better heat recovery and lower fuel consumption, driving improved process economics and sustainability.

Application Scenarios: When to Use Each System

Reboilers are primarily used in distillation columns to provide the necessary heat for vaporizing the bottom liquid, suitable for processes requiring precise temperature control and phase separation in chemical, petrochemical, and refining industries. Heaters combined with reboilers enhance thermal efficiency and are ideal for applications where preheating feed streams or maintaining specific temperature profiles is critical, such as in complex fractionation or heat-sensitive product processing. Selecting between a standalone reboiler or an integrated heater-reboiler system depends on process requirements, energy optimization, and the thermal characteristics of the feed material.

Cost Considerations and Installation Factors

Reboilers typically involve lower capital costs compared to heaters due to their simpler design and integration with distillation columns, making them cost-effective for vaporization tasks. Installation factors for reboilers emphasize ease of maintenance and compatibility with existing column configurations, whereas heaters often require more complex piping and safety measures. The operational costs of heaters can be higher, driven by fuel consumption and energy efficiency, while reboilers leverage process heat streams to reduce ongoing expenses.

Maintenance and Reliability Aspects

Reboilers and heaters differ significantly in maintenance and reliability aspects, with reboilers typically requiring more frequent inspections due to their critical role in vapor generation and high thermal stress exposure. Heaters, designed for direct heating, often experience less complex thermal cycling but need regular monitoring to prevent fouling and scaling, which can impair efficiency and reduce operational lifespan. Ensuring reliable performance involves tailored maintenance strategies, where reboilers benefit from tube cleaning and pressure testing, while heaters require burner tune-ups and combustion optimization for sustained reliability.

Industry Best Practices and Recommendations

Industry best practices recommend selecting reboilers or heaters based on process efficiency, energy consumption, and maintenance requirements. Reboilers excel in providing precise temperature control for distillation columns, optimizing vapor-liquid equilibrium and ensuring product purity. Heaters combined with reboilers enhance overall energy integration, reducing operational costs by recovering heat and minimizing thermal degradation of process fluids.

Reboiler and Heater Infographic

libterm.com

libterm.com