Continuous processes enable seamless operations and consistent output in manufacturing, ensuring high efficiency and quality. Implementing continuous systems minimizes downtime and optimizes resource utilization, crucial for maintaining competitive advantage. Explore how continuous methodologies can transform your business by reading the rest of this article.

Table of Comparison

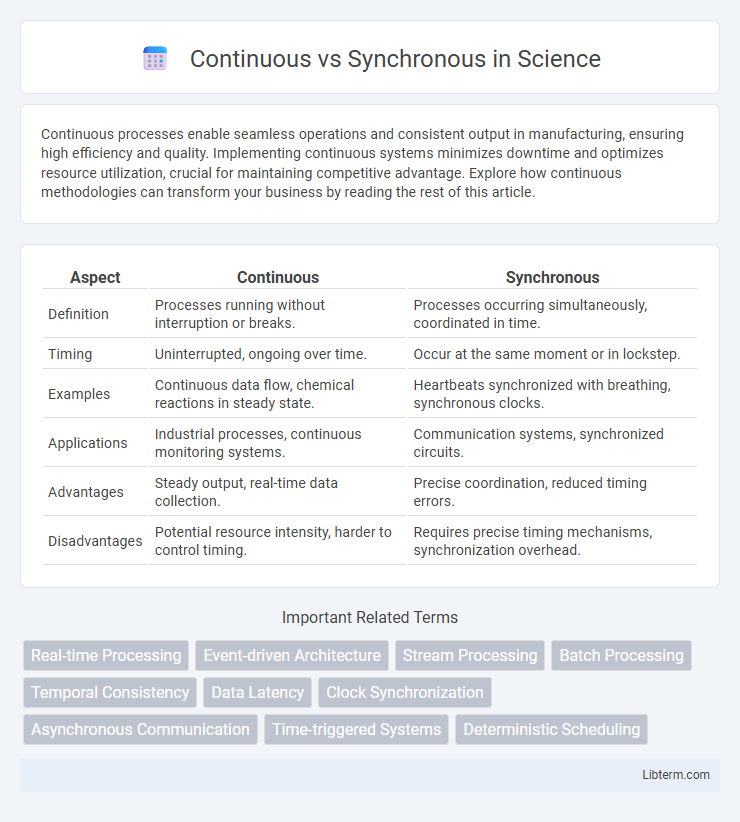

| Aspect | Continuous | Synchronous |

|---|---|---|

| Definition | Processes running without interruption or breaks. | Processes occurring simultaneously, coordinated in time. |

| Timing | Uninterrupted, ongoing over time. | Occur at the same moment or in lockstep. |

| Examples | Continuous data flow, chemical reactions in steady state. | Heartbeats synchronized with breathing, synchronous clocks. |

| Applications | Industrial processes, continuous monitoring systems. | Communication systems, synchronized circuits. |

| Advantages | Steady output, real-time data collection. | Precise coordination, reduced timing errors. |

| Disadvantages | Potential resource intensity, harder to control timing. | Requires precise timing mechanisms, synchronization overhead. |

Understanding Continuous and Synchronous Processes

Continuous processes operate without interruption, maintaining a constant flow of production, often seen in industries like chemical manufacturing or oil refining. Synchronous processes coordinate tasks to occur simultaneously or in a timed sequence, enhancing efficiency in assembly lines or just-in-time manufacturing systems. Understanding these distinctions helps optimize operational workflows by aligning process control and timing with specific production goals.

Key Differences Between Continuous and Synchronous Systems

Continuous systems operate without interruption, processing signals or data in real-time across a continuous range of values, unlike synchronous systems that function based on discrete time intervals and synchronized clock signals. Key differences include the nature of their signals--continuous systems handle analog inputs and outputs, while synchronous systems process digital signals coordinated by clock pulses. Moreover, continuous systems are prevalent in analog control and signal processing, whereas synchronous systems dominate digital communications and microprocessor timing.

Advantages of Continuous Operations

Continuous operations enhance manufacturing efficiency by minimizing downtime and ensuring consistent production flow, leading to higher throughput and reduced operational costs. This method supports real-time monitoring and adjustments, which improve product quality and reduce waste. Continuous systems also enable better scalability and flexibility in meeting market demands compared to synchronous batch processes.

Benefits of Synchronous Approaches

Synchronous approaches offer real-time interaction, enabling immediate feedback and collaboration among participants, which enhances decision-making efficiency and reduces misunderstandings. These methods foster stronger engagement through direct communication channels such as video conferencing, phone calls, or live chats. Immediate response times in synchronous settings also accelerate problem-solving and maintain project momentum.

Common Applications: Continuous vs Synchronous

Continuous manufacturing is ideal for high-volume production environments such as chemical plants, oil refineries, and food processing industries, where products are produced nonstop to ensure efficiency and consistent quality. Synchronous manufacturing suits discrete industries like automotive assembly, electronics, and aerospace, where production stages are tightly coordinated and paced to minimize downtime and inventory. Both approaches optimize workflow, but continuous excels in uniform product streams, while synchronous adapts to complex, sequenced tasks.

Challenges in Implementing Each Method

Continuous integration faces challenges such as maintaining consistent build quality and managing frequent code conflicts, which require robust automation and real-time communication among developers. Synchronous communication depends heavily on team availability and can suffer from scheduling difficulties and interruptions, leading to decreased productivity and delayed decision-making. Both methods demand careful coordination to balance workflow efficiency and minimize bottlenecks in software development.

Performance Comparison: Efficiency and Scalability

Continuous systems offer higher efficiency by processing data streams in real-time, reducing latency and enabling faster decision-making compared to synchronous systems that rely on batch processing cycles. Synchronous systems can suffer from scalability issues as workload increases, due to their dependence on fixed time intervals for synchronization, whereas continuous systems dynamically handle varying loads with minimal delay. Performance benchmarks indicate continuous processing achieves lower throughput times and better resource utilization, critical for applications demanding scalable, high-performance data handling.

Real-World Examples: Industry Use Cases

Continuous manufacturing dominates the pharmaceutical sector, enhancing process efficiency and product consistency through real-time monitoring and automation. In contrast, synchronous manufacturing is prevalent in the automotive industry, where precise coordination of assembly lines enables just-in-time production and minimizes inventory costs. Both approaches optimize operational workflows but cater to different industry demands by balancing flexibility with timing precision.

Choosing the Right Approach for Your Needs

Choosing between continuous and synchronous methods depends on your project's requirements for timing and resource allocation. Continuous processing offers uninterrupted execution ideal for real-time data streams, while synchronous approaches ensure sequential task completion suited for operations needing strict order. Evaluating workload patterns and latency tolerance helps determine the optimal approach for performance and efficiency.

Future Trends: Evolving Continuous and Synchronous Technologies

Continuous and synchronous technologies are rapidly evolving to enhance real-time data processing and seamless user experiences. Future trends emphasize the integration of AI-driven automation and edge computing to optimize latency and scalability in both continuous data streams and synchronous communications. Advances in 5G and beyond will further enable ultra-reliable low-latency connections, driving innovation in sectors like IoT, autonomous systems, and remote collaboration.

Continuous Infographic

libterm.com

libterm.com