Barcodes are essential tools for efficient inventory management and product tracking across various industries. They encode information in a visual pattern readable by scanners, streamlining checkout processes and reducing human error. Discover how barcodes can enhance your business operations by reading the rest of this article.

Table of Comparison

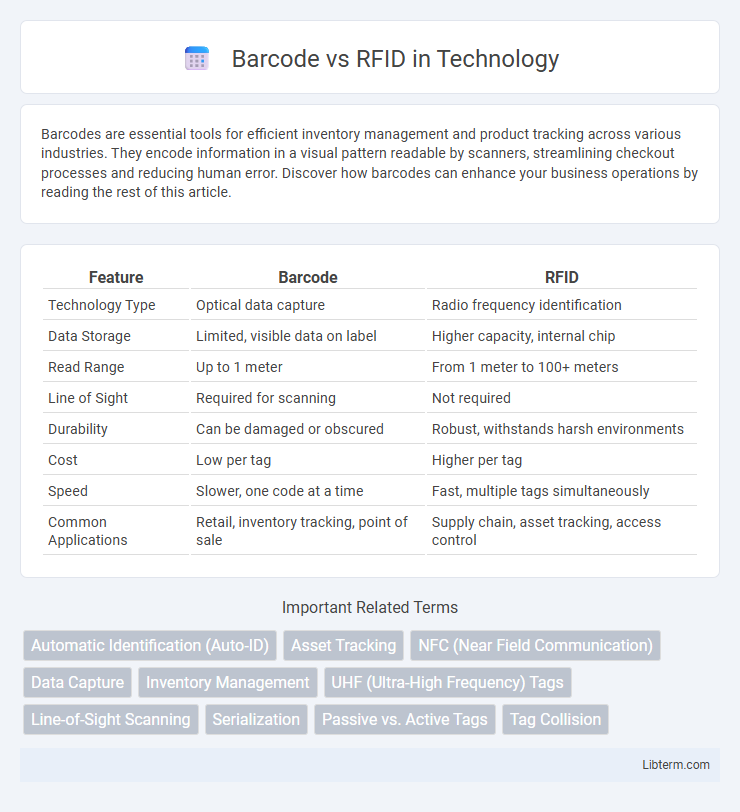

| Feature | Barcode | RFID |

|---|---|---|

| Technology Type | Optical data capture | Radio frequency identification |

| Data Storage | Limited, visible data on label | Higher capacity, internal chip |

| Read Range | Up to 1 meter | From 1 meter to 100+ meters |

| Line of Sight | Required for scanning | Not required |

| Durability | Can be damaged or obscured | Robust, withstands harsh environments |

| Cost | Low per tag | Higher per tag |

| Speed | Slower, one code at a time | Fast, multiple tags simultaneously |

| Common Applications | Retail, inventory tracking, point of sale | Supply chain, asset tracking, access control |

Introduction to Barcode and RFID Technologies

Barcode technology utilizes optical scanning to read printed patterns of parallel lines representing data, widely used for inventory and retail management due to its low cost and simplicity. RFID (Radio Frequency Identification) employs electromagnetic fields to automatically identify and track tags attached to objects, offering advantages like non-line-of-sight reading and higher data capacity. Both technologies play crucial roles in supply chain management, asset tracking, and access control, with RFID providing enhanced speed and accuracy compared to traditional barcode systems.

How Barcodes Work: A Brief Overview

Barcodes function by encoding information into a series of parallel lines and spaces that are scanned using optical readers, translating the visual pattern into digital data. This data is then processed by software systems to identify and track products or assets efficiently. The simplicity and low cost of barcode technology make it widely used in retail, logistics, and inventory management.

Understanding RFID: Fundamentals and Functionality

RFID (Radio Frequency Identification) uses electromagnetic fields to automatically identify and track tags attached to objects, offering a wireless data transfer method distinct from barcode scanning, which requires direct line-of-sight. RFID tags consist of a microchip and antenna, enabling communication with RFID readers via radio waves, providing real-time data capture and enhanced inventory management capabilities. Unlike barcodes, RFID supports multiple tag reading simultaneously, improving speed and accuracy in supply chain operations.

Barcode vs RFID: Key Differences

Barcode technology relies on optical scanning to read printed codes, making it cost-effective and widely used for inventory tracking but limited by line-of-sight requirements and susceptibility to damage. RFID (Radio Frequency Identification) uses electromagnetic fields to automatically identify tags without direct contact or visibility, offering faster data capture and enhanced durability in various environments. Key differences include read range, with RFID capable of several meters versus barcode's few centimeters, and data capacity, as RFID can store more complex information beyond simple numeric codes.

Advantages of Barcodes in Inventory Management

Barcodes offer a cost-effective solution for inventory management with easy implementation and low training requirements, making them ideal for businesses of all sizes. They provide high accuracy in tracking items and real-time data updates when scanned, reducing human errors and improving stock control. Barcode systems also ensure compatibility with most existing retail and warehouse technology, enhancing operational efficiency without the need for significant infrastructure changes.

Benefits of RFID in Asset Tracking

RFID technology offers significant benefits in asset tracking by enabling real-time, accurate data capture without line-of-sight scanning, which improves efficiency over traditional barcodes. RFID tags can be read simultaneously in bulk, reducing labor time and minimizing human error in inventory management. Enhanced durability and long-range scanning capabilities make RFID ideal for tracking assets in complex or harsh environments.

Cost Comparison: Barcode vs RFID

Barcode systems typically incur lower initial costs, including inexpensive labels and basic scanners, making them a cost-effective solution for many businesses. RFID technology demands higher upfront investments due to costly tags, specialized readers, and infrastructure requirements but offers benefits in automation and read accuracy. Over time, RFID can reduce labor expenses and inventory errors, potentially offsetting its higher initial costs in large-scale or complex supply chain operations.

Use Cases: When to Choose Barcode or RFID

Barcodes excel in inventory management, retail checkout, and asset tracking where cost efficiency and simplicity are priorities, making them ideal for smaller scale or low-budget operations. RFID is preferred in environments requiring fast, contactless scanning, such as supply chain logistics, access control, and real-time location tracking, especially in large warehouses or manufacturing plants. Choose barcode for straightforward, low-cost applications and RFID for automated, high-speed, or bulk data capture scenarios.

Common Challenges in Barcode and RFID Implementation

Barcode and RFID systems both face challenges such as environmental interference, where dirt, damage, or radio frequency noise can hinder accurate data capture. Integration with existing IT infrastructures often requires significant technical adjustments and can lead to compatibility issues. Security concerns also arise from unauthorized access or data breaches, demanding encryption and robust protocol implementation to protect sensitive information.

Future Trends in Barcode and RFID Technologies

Future trends in barcode and RFID technologies emphasize integration with IoT and AI for enhanced inventory accuracy and real-time tracking. Advanced RFID tags, such as UHF and NFC, offer extended range and multi-tag reading capabilities, enabling automated data collection across logistics and retail sectors. Barcode systems evolve with 2D codes like QR and data matrix, supporting mobile scanning and augmented reality applications for interactive consumer experiences.

Barcode Infographic

libterm.com

libterm.com