Uniformity ensures consistency and reliability across processes, products, or services by minimizing variations and maintaining standardization. This principle is crucial in industries such as manufacturing, quality control, and branding to enhance efficiency and customer trust. Discover how embracing uniformity can transform your approach and drive success in the rest of this article.

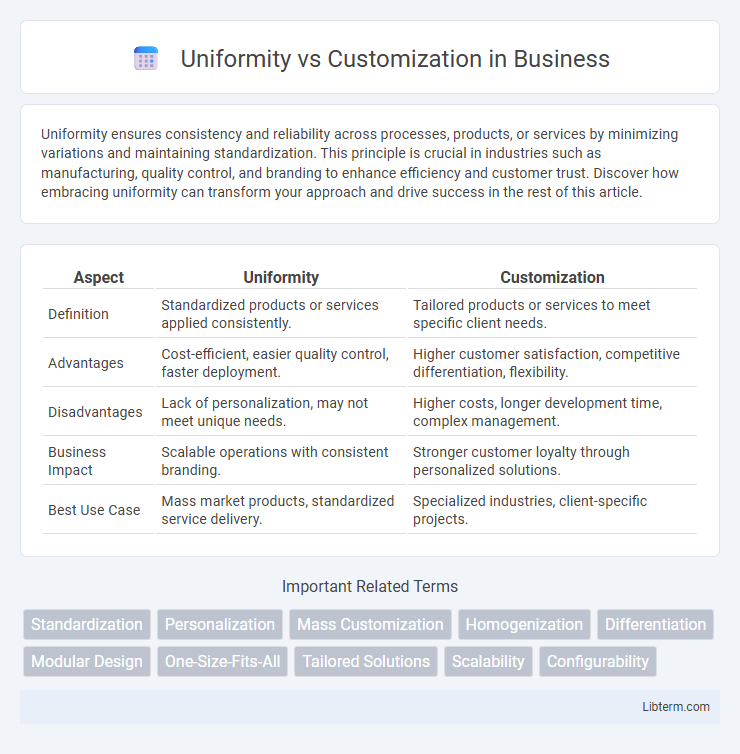

Table of Comparison

| Aspect | Uniformity | Customization |

|---|---|---|

| Definition | Standardized products or services applied consistently. | Tailored products or services to meet specific client needs. |

| Advantages | Cost-efficient, easier quality control, faster deployment. | Higher customer satisfaction, competitive differentiation, flexibility. |

| Disadvantages | Lack of personalization, may not meet unique needs. | Higher costs, longer development time, complex management. |

| Business Impact | Scalable operations with consistent branding. | Stronger customer loyalty through personalized solutions. |

| Best Use Case | Mass market products, standardized service delivery. | Specialized industries, client-specific projects. |

Introduction: Defining Uniformity and Customization

Uniformity refers to the consistent application of standardized processes, designs, or features across various contexts to ensure predictability and efficiency. Customization involves tailoring products, services, or experiences to meet specific individual preferences or requirements, enhancing relevance and satisfaction. Balancing uniformity and customization enables organizations to optimize operational efficiency while addressing diverse customer needs effectively.

Historical Perspective on Uniformity vs Customization

Historical perspectives on uniformity versus customization reveal a shift from standardized mass production during the Industrial Revolution to increasing demand for personalized goods in the late 20th century. Early manufacturing emphasized uniformity to maximize efficiency and reduce costs, exemplified by Henry Ford's assembly line techniques. The rise of digital technologies and changing consumer preferences later fueled customization, allowing brands like Nike and Apple to offer tailored products while maintaining scalable production.

Key Benefits of Uniformity

Uniformity ensures consistency across products or services, enhancing brand recognition and customer trust. It streamlines operational processes, reducing errors and increasing efficiency by standardizing procedures. Uniformity also simplifies training and compliance, leading to cost savings and improved quality control.

Advantages of Customization

Customization enhances user satisfaction by tailoring products or services to individual preferences, increasing engagement and loyalty. It allows businesses to address specific needs, resulting in higher accuracy and better performance compared to uniform solutions. Personalized offerings also create competitive advantages by differentiating brands and fostering stronger customer relationships.

Challenges and Limitations of Uniform Solutions

Uniform solutions often struggle to address diverse user needs due to their rigid frameworks, leading to decreased satisfaction and effectiveness. Challenges include lack of adaptability in varying cultural, operational, and technological contexts, which can hinder innovation and responsiveness. Limitations of uniformity manifest in reduced personalization, scalability issues, and potential incompatibility with evolving market demands.

Drawbacks of Customization

Customization can lead to increased complexity and higher costs in production and maintenance, as tailored solutions often require specialized resources and expertise. It may also slow down scalability and integration efforts because unique features must be supported across diverse systems and platforms. Furthermore, excessive customization risks fragmenting user experiences, resulting in inconsistency and potential confusion among end-users.

Industry-Specific Applications: Uniformity vs Customization

Industry-specific applications demand a strategic balance between uniformity and customization to maximize operational efficiency and user satisfaction. Uniformity ensures consistent performance, easier maintenance, and streamlined updates across enterprise systems, critical in regulated sectors like finance and healthcare. Customization tailors functionality to meet niche workflows, enhances user engagement, and supports unique compliance requirements, proving essential in specialized industries such as manufacturing and logistics.

Consumer Preferences and Market Trends

Consumer preferences increasingly favor customization, reflecting a demand for personalized products and services that cater to individual tastes and lifestyles. Market trends show a shift towards flexible production methods and digital technologies enabling companies to offer tailored solutions at scale. Uniformity remains relevant for cost efficiency and brand consistency, but the competitive advantage lies in balancing standardization with customization to meet diverse consumer needs.

Striking the Right Balance: Hybrid Approaches

Hybrid approaches blend uniformity and customization to optimize operational efficiency while addressing diverse customer needs. By implementing standardized core processes alongside flexible, tailored solutions, businesses achieve scalability without sacrificing personalization. This balance drives enhanced user satisfaction, brand consistency, and adaptive innovation across multiple sectors.

Future Outlook: Evolving Trends in Uniformity and Customization

The future outlook in uniformity and customization reveals a shift towards hybrid models that leverage advanced technologies such as AI and 3D printing to deliver personalized yet consistent products. Industries like fashion, automotive, and consumer electronics increasingly adopt modular designs enabling scalable customization while maintaining brand uniformity. Emerging trends emphasize sustainability and ethical production, driving innovations that balance standardized manufacturing processes with individualized consumer preferences.

Uniformity Infographic

libterm.com

libterm.com