Backward integration strengthens your supply chain by allowing direct control over raw materials and production processes, reducing costs and dependency on suppliers. This strategy enhances operational efficiency and can improve product quality and lead times. Explore the rest of the article to understand how backward integration can benefit your business and the steps to implement it effectively.

Table of Comparison

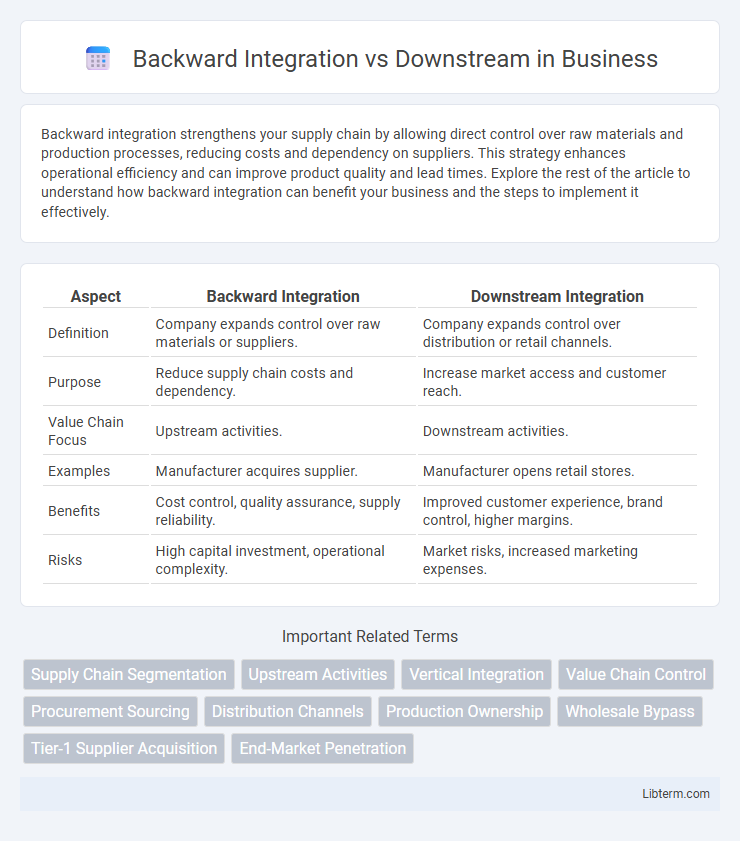

| Aspect | Backward Integration | Downstream Integration |

|---|---|---|

| Definition | Company expands control over raw materials or suppliers. | Company expands control over distribution or retail channels. |

| Purpose | Reduce supply chain costs and dependency. | Increase market access and customer reach. |

| Value Chain Focus | Upstream activities. | Downstream activities. |

| Examples | Manufacturer acquires supplier. | Manufacturer opens retail stores. |

| Benefits | Cost control, quality assurance, supply reliability. | Improved customer experience, brand control, higher margins. |

| Risks | High capital investment, operational complexity. | Market risks, increased marketing expenses. |

Introduction to Backward Integration and Downstream Strategies

Backward integration involves a company expanding its operations to control its supply chain by acquiring or merging with suppliers, enhancing cost efficiency and supply reliability. Downstream strategies focus on controlling distribution channels and retail outlets to directly reach customers, improving market presence and customer experience. Both approaches aim to increase competitive advantage by managing different stages of the production and delivery process.

Defining Backward Integration

Backward integration involves a company expanding its operations to control or own its suppliers, enabling direct control over raw materials or components essential for production. This strategy enhances supply chain reliability, reduces costs, and improves bargaining power by cutting out intermediaries. Downstream integration, in contrast, refers to controlling the distribution and sales activities, focusing on reaching end customers more effectively.

Understanding Downstream Operations

Downstream operations in the oil and gas industry involve refining, distribution, and marketing of petroleum products to end-users, optimizing supply chain efficiency and product availability. These processes focus on converting crude oil into usable products such as gasoline, diesel, and petrochemicals, thereby adding significant value to raw materials. Understanding downstream operations enables companies to enhance customer satisfaction and maximize profit margins through effective inventory management and market responsiveness.

Key Differences Between Backward Integration and Downstream

Backward integration involves a company expanding its operations to control its suppliers or raw materials, enhancing supply chain control and reducing dependency on external sources. Downstream integration focuses on acquiring or merging with distribution channels or retailers to gain direct access to customers and enhance market reach. The key difference lies in the operational direction: backward integration moves toward raw material sources, while downstream integration moves toward the end consumer.

Benefits of Backward Integration

Backward integration enhances supply chain control by allowing businesses to own or manage their suppliers, leading to reduced costs and improved quality assurance. It increases operational efficiency through better coordination and reduces dependency on external vendors, mitigating risks of supply disruptions. This strategy also enables companies to capture higher profit margins by eliminating intermediary markup and gaining direct access to raw materials.

Advantages of Downstream Integration

Downstream integration enhances control over product distribution and customer experience, leading to increased market reach and brand loyalty. It reduces dependency on third-party retailers, improving profit margins by capturing more value from the supply chain. Moreover, downstream integration allows for better market intelligence and faster response to consumer demand fluctuations.

Risks and Challenges of Each Strategy

Backward integration risks include high upfront capital investment and potential supply chain disruptions if upstream operations fail to perform efficiently. Challenges also arise from managing unfamiliar production processes and increased operational complexity. Downstream integration faces risks like market volatility and customer demand fluctuations, with challenges in building strong brand presence and effective distribution networks to capture end-consumer value.

Industry Examples: Backward Integration vs Downstream

Backward integration refers to a company acquiring or merging with its suppliers to control the supply chain, exemplified by Tesla's acquisition of battery manufacturers to secure essential components. Downstream integration involves firms extending operations toward the end consumers, such as ExxonMobil's extensive network of retail gas stations that directly sell fuel to customers. Both strategies enhance market control but target different stages of the supply chain in industries like automotive and oil refining.

Strategic Considerations for Choosing the Right Approach

Choosing between backward integration and downstream strategies hinges on a company's core competencies and market positioning. Backward integration strengthens supply chain control and reduces dependency on suppliers, offering cost advantages and quality assurance in raw materials acquisition. Downstream integration enhances market reach and customer engagement by controlling distribution and retail channels, essential for companies prioritizing brand experience and direct consumer relationships.

Future Trends in Integration Strategies

Backward integration is expected to evolve with increased adoption of advanced technologies such as AI and blockchain to enhance supply chain transparency and reduce dependency on third-party suppliers. Downstream integration will likely focus on personalized customer experiences and direct-to-consumer channels, leveraging data analytics and digital platforms for real-time demand forecasting. Future integration strategies emphasize seamless coordination between upstream and downstream processes to create agile, resilient supply networks that drive competitive advantage.

Backward Integration Infographic

libterm.com

libterm.com