Learning curve effects describe how increased experience leads to higher efficiency and reduced costs in production or task performance. Businesses leverage these effects to optimize processes, improve quality, and gain competitive advantages by systematically analyzing historical data and employee skill development. Explore the rest of the article to understand how learning curve effects can transform your operational strategy.

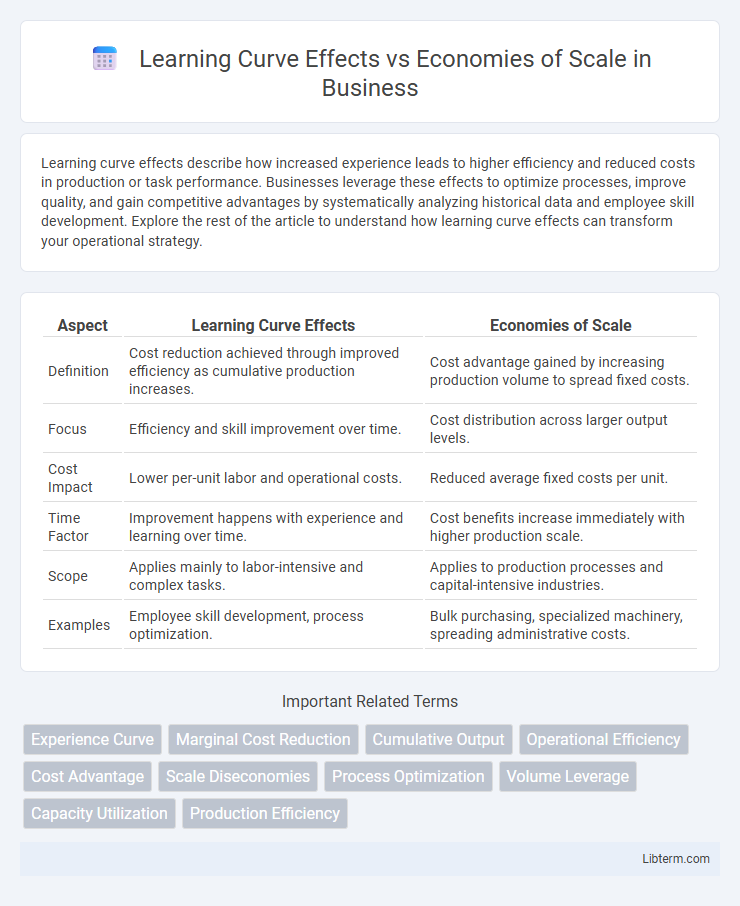

Table of Comparison

| Aspect | Learning Curve Effects | Economies of Scale |

|---|---|---|

| Definition | Cost reduction achieved through improved efficiency as cumulative production increases. | Cost advantage gained by increasing production volume to spread fixed costs. |

| Focus | Efficiency and skill improvement over time. | Cost distribution across larger output levels. |

| Cost Impact | Lower per-unit labor and operational costs. | Reduced average fixed costs per unit. |

| Time Factor | Improvement happens with experience and learning over time. | Cost benefits increase immediately with higher production scale. |

| Scope | Applies mainly to labor-intensive and complex tasks. | Applies to production processes and capital-intensive industries. |

| Examples | Employee skill development, process optimization. | Bulk purchasing, specialized machinery, spreading administrative costs. |

Introduction to Learning Curve Effects and Economies of Scale

Learning Curve Effects describe the reduction in unit costs as cumulative production increases, driven by improved efficiency and worker proficiency. Economies of Scale occur when average costs decrease as output volume rises, due to fixed cost distribution and operational synergies. Both concepts highlight cost advantages but differ in that Learning Curve Effects emphasize experience gains over time, while Economies of Scale focus on size and capacity factors.

Defining Learning Curve Effects

Learning curve effects describe the reduction in unit production costs as workers gain experience and improve efficiency over time. This concept emphasizes how cumulative output leads to faster production processes, innovation, and reduced errors, driving cost declines independent of production scale. Learning curve effects differ from economies of scale, which rely primarily on cost advantages gained through increased production volume and resource utilization.

Understanding Economies of Scale

Economies of scale refer to the cost advantages that enterprises obtain due to their scale of operation, with cost per unit of output generally decreasing as scale increases. These cost reductions arise from factors such as bulk purchasing of materials, more efficient production techniques, and spreading fixed costs over a larger output. Understanding economies of scale is essential for businesses aiming to enhance competitiveness by minimizing average costs and increasing profitability through expanded production capacity.

Key Differences Between Learning Curve Effects and Economies of Scale

Learning curve effects describe the reduction in per-unit labor hours as cumulative production experience increases, highlighting efficiency gains from workforce skill improvement and process familiarity. Economies of scale refer to cost advantages achieved as output volume rises, resulting from fixed cost dilution, bulk purchasing, and operational efficiencies. The key difference lies in learning curve effects emphasizing time-based experience per unit, whereas economies of scale focus on cost benefits due to expanded production scale.

Factors Influencing Learning Curve Effects

Learning curve effects are influenced primarily by factors such as workforce experience, repetition of tasks, technological improvements, and organizational learning processes. Increased employee proficiency and enhanced process standardization lead to reduced production time and costs as cumulative output rises. Technological advancements and systematic knowledge transfer further accelerate efficiency gains, distinguishing learning curve effects from economies of scale, which are driven by production volume rather than process mastery.

Drivers of Economies of Scale

Economies of scale are driven primarily by factors such as operational efficiencies, bulk purchasing, and spreading fixed costs over increased production volumes, reducing average costs per unit. Learning curve effects, however, stem from improvements in workforce skills and process optimizations that enhance productivity over time. Key drivers of economies of scale include technological advancements, enhanced labor specialization, and optimized supply chain management.

Real-world Examples: Learning Curve vs Economies of Scale

Learning curve effects are evident in industries like aerospace manufacturing, where increased worker experience reduces production time and costs per unit over successive batches. Economies of scale appear prominently in automobile production plants, where larger factory size enables the spreading of fixed costs over millions of vehicles, lowering per-unit expenses. Both concepts drive cost efficiencies but learning curves rely on gained expertise, while economies of scale depend on increased operational scale.

Implications for Business Strategy

Learning curve effects lead to cost reductions through increased worker proficiency and process improvements, emphasizing the importance of experience accumulation in business strategy. Economies of scale reduce average costs by expanding production volume, focusing strategic efforts on scaling operations and optimizing resource allocation. Businesses that integrate both concepts can create competitive advantages by enhancing efficiency while expanding market share.

Challenges in Leveraging Learning Curve and Scale Economies

Learning curve effects challenge organizations with the need for continuous process improvements and employee skill development, often requiring significant time and investment before cost reductions become evident. Economies of scale demand substantial capital outlays and market expansion strategies, which can introduce risks related to overcapacity, operational complexity, and diminished flexibility. Balancing these factors while maintaining quality and innovation remains a critical difficulty for firms seeking to optimize production efficiency and competitive advantage.

Conclusion: Maximizing Efficiency through Learning and Scale

Maximizing efficiency in production relies on harnessing both learning curve effects and economies of scale, where learning curve effects reduce costs through improved proficiency and operational knowledge over time, while economies of scale lower unit costs by expanding output and spreading fixed costs. Integrating continuous process improvements with strategic scaling enables firms to achieve optimal cost advantages and competitive positioning. Businesses that simultaneously invest in workforce skill development and capacity expansion gain sustainable efficiency and profitability benefits.

Learning Curve Effects Infographic

libterm.com

libterm.com