Vertical integration streamlines your supply chain by consolidating production and distribution under one organization, reducing costs and improving efficiency. This strategy enhances control over product quality, inventory management, and market responsiveness, leading to competitive advantages. Discover how vertical integration can transform your business operations by exploring the rest of the article.

Table of Comparison

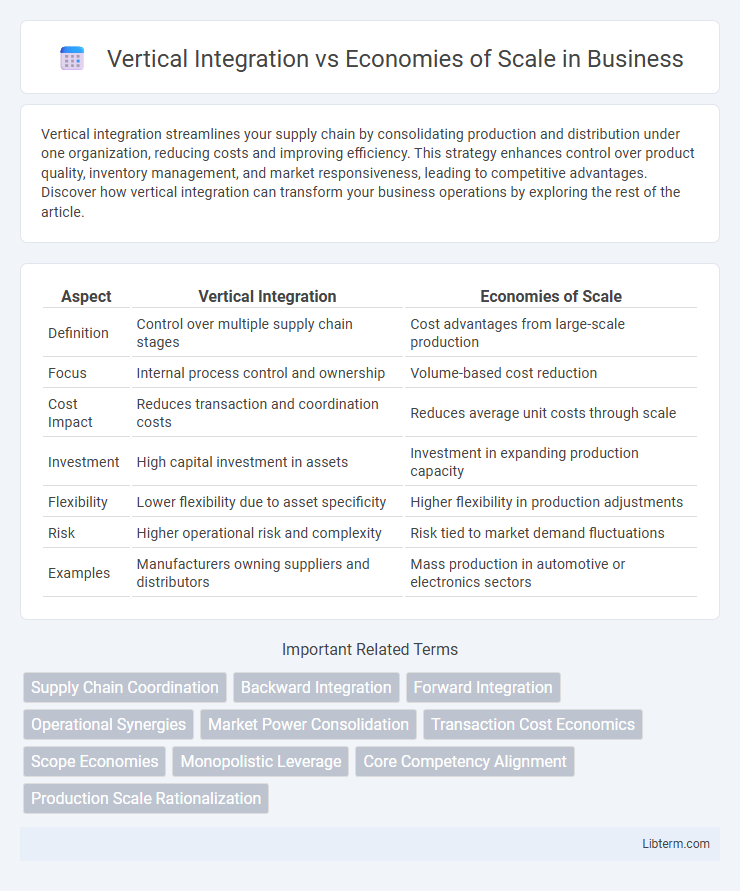

| Aspect | Vertical Integration | Economies of Scale |

|---|---|---|

| Definition | Control over multiple supply chain stages | Cost advantages from large-scale production |

| Focus | Internal process control and ownership | Volume-based cost reduction |

| Cost Impact | Reduces transaction and coordination costs | Reduces average unit costs through scale |

| Investment | High capital investment in assets | Investment in expanding production capacity |

| Flexibility | Lower flexibility due to asset specificity | Higher flexibility in production adjustments |

| Risk | Higher operational risk and complexity | Risk tied to market demand fluctuations |

| Examples | Manufacturers owning suppliers and distributors | Mass production in automotive or electronics sectors |

Introduction to Vertical Integration and Economies of Scale

Vertical integration involves a company expanding its operations into different stages of production within the same industry, aiming to control the supply chain and reduce costs. Economies of scale occur when increased production leads to lower average costs due to factors like bulk purchasing, specialized labor, and more efficient use of capital. Both strategies seek cost reduction but differ in scope: vertical integration focuses on controlling multiple production phases, while economies of scale emphasize scaling up production within a single phase.

Defining Vertical Integration

Vertical integration refers to a company's control over multiple stages of production or distribution within the same industry, enhancing efficiency and reducing reliance on external suppliers. This strategic approach contrasts with economies of scale, which focus on cost advantages gained through increased production volume. Vertical integration can lead to improved supply chain coordination, lower transaction costs, and greater market power.

Understanding Economies of Scale

Economies of scale refer to the cost advantages that enterprises obtain due to their scale of operation, with cost per unit of output generally decreasing with increasing scale. This phenomenon occurs because fixed costs are spread over more units, operational efficiencies improve, and bulk purchasing reduces input prices. Understanding economies of scale is crucial for businesses seeking to enhance profitability through expansion or optimized production processes, distinct from vertical integration which involves controlling multiple stages of the supply chain.

Core Differences Between Vertical Integration and Economies of Scale

Vertical integration involves a company controlling multiple stages of the supply chain, enhancing coordination and reducing transaction costs, while economies of scale refer to cost advantages gained by increasing production volume to lower per-unit costs. Vertical integration emphasizes control and ownership across production processes, whereas economies of scale focus on efficiency through expanded output. The core difference lies in vertical integration managing supply chain activities internally, contrasted with economies of scale optimizing cost through production size irrespective of ownership structure.

Benefits of Vertical Integration

Vertical integration enhances control over the supply chain, reduces dependency on suppliers, and improves production efficiency. It enables firms to capture more value by internalizing processes, leading to cost savings and improved quality control. By coordinating operations across stages, companies can streamline workflows and respond faster to market changes, ultimately boosting competitive advantage.

Advantages of Achieving Economies of Scale

Achieving economies of scale allows businesses to reduce average costs by increasing production volume, leading to higher profit margins and competitive pricing. Large-scale operations enable purchasing inputs in bulk at discounted rates and optimizing resource utilization, which drives efficiency and cost leadership. This scalability supports market expansion and innovation investments, reinforcing long-term growth and industry dominance.

Challenges in Implementing Vertical Integration

Implementing vertical integration poses significant challenges including high capital investment and increased operational complexity due to managing multiple stages of the supply chain. Companies often face risks of reduced flexibility and slower response to market changes, as integrating upstream or downstream processes can create dependency and inefficiency. Moreover, coordination difficulties and potential regulatory scrutiny can hinder the seamless execution of vertical integration strategies.

Limitations and Risks of Economies of Scale

Economies of scale face limitations such as diseconomies of scale, where increased production leads to higher average costs due to factors like management inefficiencies and communication breakdowns. Risks include over-reliance on high volume demand, vulnerability to market fluctuations, and reduced flexibility in responding to changing consumer preferences. Large-scale operations also encounter complexities in logistics and quality control that can erode anticipated cost advantages.

Industry Examples: Vertical Integration vs. Economies of Scale

Vertical integration in the automotive industry, exemplified by Tesla's control over battery production and vehicle assembly, contrasts with Ford's use of economies of scale through mass production and supplier networks to reduce costs. In technology, Apple employs vertical integration by designing both hardware and software, while semiconductor manufacturers like Samsung leverage economies of scale by producing vast quantities of chips efficiently. These strategies illustrate how controlled supply chains and large-scale production independently drive competitive advantages across diverse sectors.

Strategic Considerations: Choosing the Best Approach

Vertical integration enhances control over supply chains, reduces transaction costs, and secures critical resources, making it ideal for industries with volatile input prices or high coordination needs. Economies of scale drive cost advantages through increased production volume, benefiting firms in mass production sectors with standardized outputs and stable demand. Strategic considerations hinge on industry characteristics, market dynamics, and resource capabilities to determine whether controlling upstream and downstream activities or maximizing operational efficiency yields superior competitive advantage.

Vertical Integration Infographic

libterm.com

libterm.com