Effective supply chain management ensures seamless coordination between suppliers, manufacturers, and retailers to optimize inventory levels and reduce costs. Advanced technologies like AI and blockchain enhance transparency, traceability, and efficiency across the entire supply chain network. Discover how your business can leverage these innovations to gain a competitive edge in the full article.

Table of Comparison

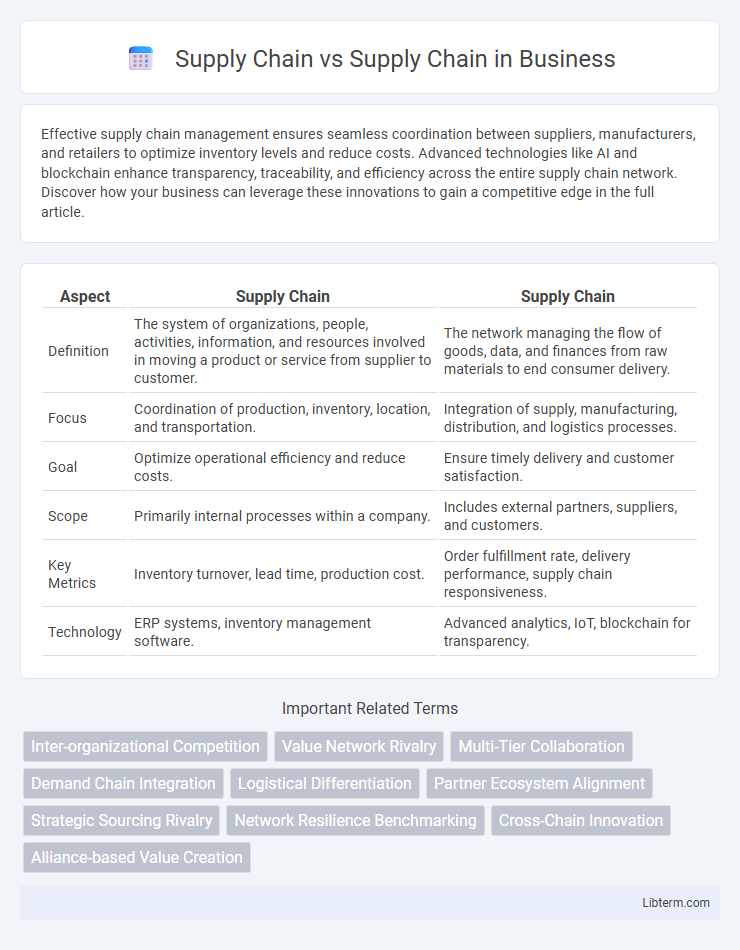

| Aspect | Supply Chain | Supply Chain |

|---|---|---|

| Definition | The system of organizations, people, activities, information, and resources involved in moving a product or service from supplier to customer. | The network managing the flow of goods, data, and finances from raw materials to end consumer delivery. |

| Focus | Coordination of production, inventory, location, and transportation. | Integration of supply, manufacturing, distribution, and logistics processes. |

| Goal | Optimize operational efficiency and reduce costs. | Ensure timely delivery and customer satisfaction. |

| Scope | Primarily internal processes within a company. | Includes external partners, suppliers, and customers. |

| Key Metrics | Inventory turnover, lead time, production cost. | Order fulfillment rate, delivery performance, supply chain responsiveness. |

| Technology | ERP systems, inventory management software. | Advanced analytics, IoT, blockchain for transparency. |

Understanding the Concept of Supply Chain vs Supply Chain

Understanding the concept of supply chain involves recognizing the entire network that manages the flow of goods, information, and finances from raw material suppliers to end consumers. Supply chain management emphasizes optimizing processes such as procurement, production, distribution, and logistics to enhance efficiency and reduce costs. Differentiating supply chain from supply network highlights the linear flow in a supply chain compared to the complex, interconnected relationships in supply networks.

Key Differences Between Competing Supply Chains

Competing supply chains differ primarily in efficiency, cost management, and responsiveness to market demands. Advanced supply chains leverage technology integration, real-time data analytics, and automation to optimize inventory levels and reduce lead times, outperforming traditional supply chains that rely on manual processes and outdated systems. Companies with agile supply chains achieve higher customer satisfaction and adaptability, ensuring competitive advantage in dynamic global markets.

Factors Driving Supply Chain vs Supply Chain Competition

Factors driving supply chain competition include technological advancements, customer demand for faster delivery, and increasing global trade complexities. Companies leverage data analytics, automation, and sustainable practices to enhance operational efficiency and responsiveness. Performance metrics such as cost reduction, agility, and service quality determine competitive advantage in supply chain management.

The Role of Technology in Modern Supply Chain Rivalry

Technology drives competitive advantage in modern supply chains by enabling real-time data analytics, automation, and enhanced visibility across the entire network. Advanced tools like AI, blockchain, and IoT optimize demand forecasting, inventory management, and logistics, reducing costs and increasing responsiveness. Companies leveraging these innovations outperform rivals by improving efficiency, agility, and customer satisfaction in a dynamic global market.

Assessing Supply Chain Efficiency: Metrics and KPIs

Supply chain efficiency is assessed using critical metrics such as order fulfillment cycle time, inventory turnover, and perfect order rate, which provide quantitative measures of performance. Key performance indicators (KPIs) like warehouse accuracy, transportation costs, and supplier lead time enable precise benchmarking of operational effectiveness across supply chains. Utilizing these data-driven insights helps identify bottlenecks, optimize resource allocation, and enhance overall supply chain responsiveness.

Impact of Globalization on Supply Chain Competition

Globalization has intensified supply chain competition by expanding market reach and increasing access to diverse suppliers worldwide, enabling companies to optimize cost-efficiency and innovation. The complexity and interconnectivity of global supply chains demand advanced logistics, real-time data analytics, and agile decision-making to maintain competitive advantage. Companies investing in digital transformation and sustainable practices gain resilience, reducing risks associated with geopolitical disruptions and fluctuating trade policies.

Strategies for Gaining a Competitive Supply Chain Advantage

Implementing advanced demand forecasting and lean inventory management strategies significantly enhances supply chain responsiveness and reduces operational costs. Leveraging technology such as AI-driven analytics and blockchain improves transparency, traceability, and decision-making accuracy across the supply chain network. Strategic collaboration with suppliers and logistics partners enables faster innovation cycles and increases supply chain flexibility, creating a sustainable competitive advantage.

Case Studies: Successful Supply Chain vs Supply Chain Examples

Successful supply chain case studies often highlight companies like Amazon and Walmart, which utilize advanced logistics and real-time data analytics to optimize inventory management and reduce delivery times. In contrast, supply chain examples with less favorable outcomes, such as the 2011 Toyota recall crisis, demonstrate how inadequate quality control and lack of supplier coordination can lead to massive operational disruptions. These comparisons emphasize the critical role of integrated technology, effective communication, and risk management in achieving supply chain excellence.

Challenges in Managing Competitive Supply Chains

Managing competitive supply chains involves overcoming challenges such as demand variability, supplier reliability, and inventory optimization to maintain efficiency and responsiveness. Companies face difficulties integrating advanced technologies like IoT and AI to enhance transparency and real-time decision-making across global networks. Balancing cost reduction with agility and sustainability efforts adds complexity to supply chain risk management and stakeholder collaboration.

Future Trends in Supply Chain vs Supply Chain Dynamics

Future trends in supply chain emphasize increased automation, artificial intelligence integration, and sustainability efforts to enhance efficiency and reduce environmental impact. Supply chain dynamics focus on the real-time responsiveness to market fluctuations, demand variability, and geopolitical disruptions, highlighting the need for agility and risk management. Together, these elements drive the evolution of supply chains toward more resilient, data-driven, and adaptive networks.

Supply Chain Infographic

libterm.com

libterm.com