Filtration effectively removes impurities and contaminants from liquids or gases by passing them through a selective barrier, ensuring cleaner, safer outputs. Different filtration methods, such as mechanical, chemical, and biological, cater to various industrial and environmental needs. Discover how filtration technology can enhance your processes by exploring the rest of this article.

Table of Comparison

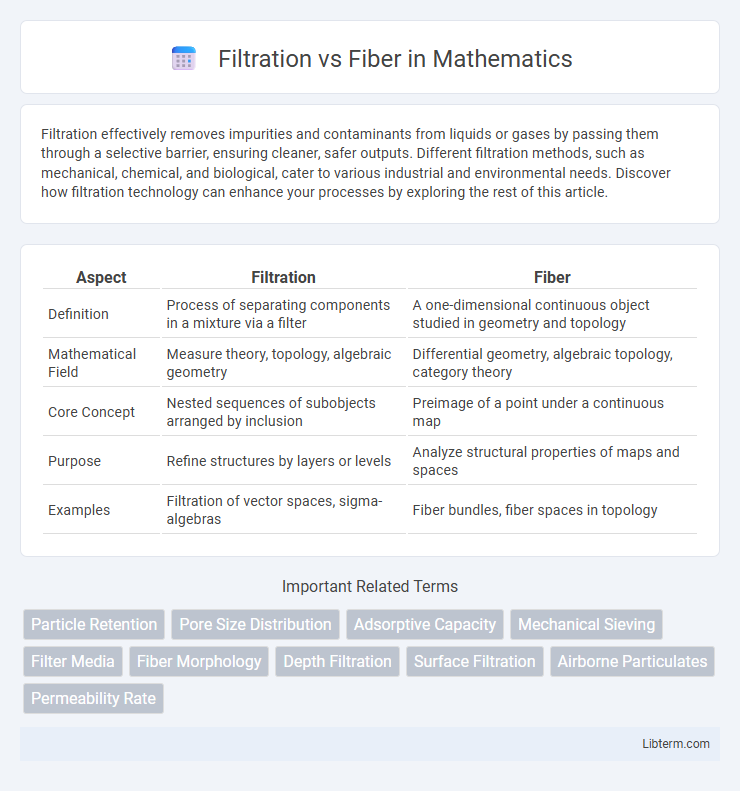

| Aspect | Filtration | Fiber |

|---|---|---|

| Definition | Process of separating components in a mixture via a filter | A one-dimensional continuous object studied in geometry and topology |

| Mathematical Field | Measure theory, topology, algebraic geometry | Differential geometry, algebraic topology, category theory |

| Core Concept | Nested sequences of subobjects arranged by inclusion | Preimage of a point under a continuous map |

| Purpose | Refine structures by layers or levels | Analyze structural properties of maps and spaces |

| Examples | Filtration of vector spaces, sigma-algebras | Fiber bundles, fiber spaces in topology |

Introduction to Filtration and Fiber

Filtration involves separating particles from fluids or gases by passing the mixture through a porous medium that traps contaminants based on size or chemical properties. Fiber-based filtration uses specialized fibers arranged in mats or membranes to capture pollutants effectively, offering high surface area and customizable pore structure for targeted filtration. Key materials include synthetic fibers like polypropylene and natural fibers such as cellulose, chosen for their durability, permeability, and adsorption capabilities in industrial and environmental applications.

Defining Filtration: Processes and Applications

Filtration involves the separation of solids from fluids using a porous medium to remove contaminants and particles, enhancing purity and safety in various industries. Common processes include mechanical filtration, membrane filtration, and biological filtration, each tailored for specific applications such as water treatment, air purification, and chemical manufacturing. Fiber filtration utilizes materials like fiberglass or synthetic fibers to trap particulates efficiently, optimizing performance in HVAC systems, industrial dust collection, and medical respiratory devices.

Understanding Fiber: Types and Uses

Fiber is categorized into natural fibers like cotton and wool, and synthetic fibers including polyester and nylon, each offering distinct properties beneficial for various applications. Natural fibers excel in breathability and biodegradability, making them ideal for clothing and home textiles, while synthetic fibers provide strength, elasticity, and water resistance, commonly used in industrial fabrics and outdoor gear. Understanding these types allows for informed decisions in selecting fibers that match specific filtration needs, durability requirements, or comfort preferences.

Key Differences Between Filtration and Fiber

Filtration primarily involves removing particles from liquids or gases using mechanical, chemical, or biological processes, while fiber refers to natural or synthetic threads used in textiles, composites, or reinforcements. Filtration systems rely on filter media which can include fibers, but fibers themselves serve as building blocks for materials rather than a separation process. Key differences include filtration's functional role in purification and separation versus fiber's structural use in manufacturing and material strength.

How Filtration Works in Industrial Settings

Filtration in industrial settings operates by separating solid particles from liquids or gases using physical barriers like filter media made of fibers, meshes, or membranes. The process relies on mechanisms such as mechanical sieving, depth filtration, and surface filtration to capture contaminants while allowing the clean fluid to pass through. High-efficiency filters, including HEPA filters and activated carbon fibers, enhance purification by trapping particles down to micrometer or nanometer scales, optimizing performance in manufacturing, chemical processing, and air quality control.

Fiber Technology in Modern Filtration Systems

Fiber technology in modern filtration systems enhances particle capture efficiency by utilizing micro- and nano-scale fibers that create a dense yet breathable matrix. These fibers increase surface area and improve filtration performance for contaminants such as dust, bacteria, and pollutants without compromising airflow. Advanced materials like electrospun nanofibers and synthetic microfibers are key innovations driving superior filtration in HVAC, medical, and industrial applications.

Advantages of Filtration Over Fiber Solutions

Filtration systems offer superior particle removal efficiency compared to fiber solutions, ensuring cleaner air or liquids by capturing smaller contaminants. Advanced filtration technologies provide longer service life and easier maintenance, reducing operational costs and downtime. They also allow for scalable customization based on specific industrial or environmental requirements, enhancing overall performance and reliability.

Benefits of Fiber in Air and Water Purification

Fiber-based filtration systems offer superior contaminant capture due to their high surface area and fine pore structure, enhancing air and water purification efficiency. These fibers can target microscopic particles, bacteria, and allergens, improving overall air quality and water safety while reducing energy consumption compared to traditional filtration methods. Durable and customizable fiber materials ensure longer lifespan and cost-effectiveness in diverse environmental conditions.

Filtration vs Fiber: Choosing the Right Method

Filtration and fiber-based methods both serve crucial roles in material separation and purification, yet they differ significantly in mechanism and application. Filtration relies on physical barriers to separate particles based on size and is ideal for liquids and gases with particulate matter, while fiber methods employ fibrous materials to trap contaminants through entanglement and adsorption, excelling in air filtration and water treatment. Selecting the right method depends on factors such as particle size, flow rate, chemical compatibility, and the specific requirements of the filtration or purification process.

Future Trends in Filtration and Fiber Technology

Emerging advancements in filtration technology emphasize smart filters integrating nanofibers for enhanced particle capture and energy efficiency, crucial for air and water purification systems. Fiber technology is rapidly evolving with the development of bio-based and multifunctional fibers that offer sustainability alongside improved mechanical and filtration properties. Future trends highlight the convergence of IoT-enabled filtration devices and adaptive fiber materials to optimize performance across environmental and industrial applications.

Filtration Infographic

libterm.com

libterm.com