Elastic materials return to their original shape after deformation, making them essential in various engineering and everyday applications. Understanding the principles of elasticity can improve the design and durability of products you rely on daily. Discover more insights about elasticity and how it impacts the objects around you by reading the full article.

Table of Comparison

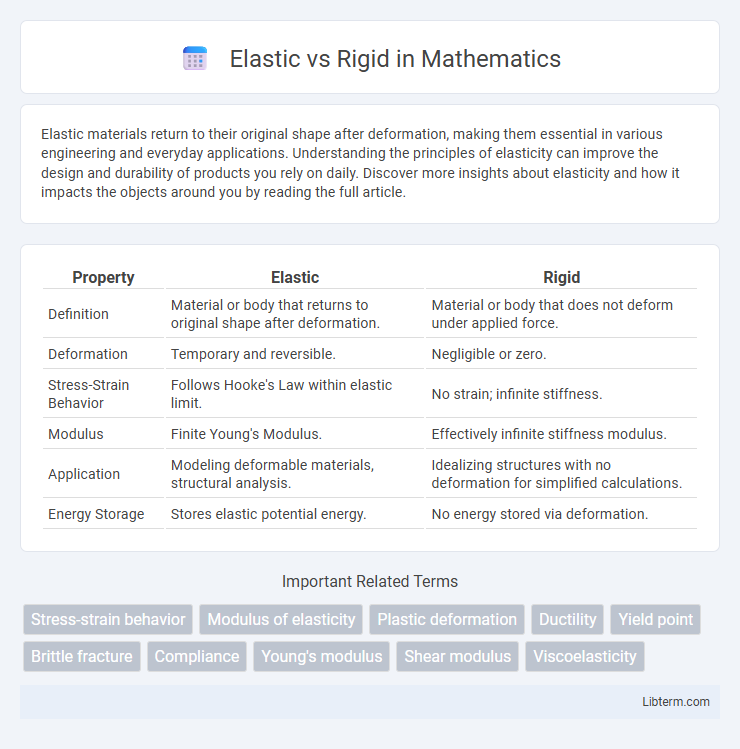

| Property | Elastic | Rigid |

|---|---|---|

| Definition | Material or body that returns to original shape after deformation. | Material or body that does not deform under applied force. |

| Deformation | Temporary and reversible. | Negligible or zero. |

| Stress-Strain Behavior | Follows Hooke's Law within elastic limit. | No strain; infinite stiffness. |

| Modulus | Finite Young's Modulus. | Effectively infinite stiffness modulus. |

| Application | Modeling deformable materials, structural analysis. | Idealizing structures with no deformation for simplified calculations. |

| Energy Storage | Stores elastic potential energy. | No energy stored via deformation. |

Introduction to Elastic and Rigid Concepts

Elastic materials return to their original shape after deformation due to their ability to store and release elastic potential energy, governed by Hooke's Law which describes the linear relationship between stress and strain within the elastic limit. Rigid materials resist deformation and maintain their shape under applied forces, exhibiting minimal elastic strain and primarily experiencing plastic deformation when subjected to stress beyond their yield point. Understanding the distinction between elastic and rigid properties is essential in fields like materials science and structural engineering for selecting appropriate materials based on flexibility and strength requirements.

Defining Elasticity and Rigidity

Elasticity describes a material's ability to return to its original shape after being deformed by an external force, characterized by reversible deformation and measured using the modulus of elasticity. Rigidity refers to a material's resistance to deformation, indicating a high modulus of rigidity and minimal shape change under applied stress. Understanding the differences between elasticity and rigidity is crucial for designing structures that require flexibility or structural stability.

Key Differences Between Elastic and Rigid Materials

Elastic materials deform under stress but return to their original shape once the stress is removed, displaying reversible deformation characterized by a measurable modulus of elasticity. Rigid materials resist deformation and retain their shape under applied forces, exhibiting high stiffness and typically undergoing brittle failure without significant elastic strain. The key difference lies in the stress-strain response: elastic materials exhibit linear elasticity within their elastic limit, while rigid materials have minimal elastic region and high yield strength, leading to permanent deformation or fracture.

Real-World Applications of Elastic Materials

Elastic materials, such as rubber and certain polymers, are widely used in real-world applications requiring flexibility and energy absorption, including automotive tires, medical gloves, and wearable technology. Their ability to undergo significant deformation and return to their original shape makes them ideal for shock absorbers, seals, and flexible electronic components. Unlike rigid materials, elastic materials provide durability and resilience in applications demanding repeated stretching and bending.

Common Uses of Rigid Materials

Rigid materials are commonly used in construction for structural components such as beams, columns, and supports due to their high strength and stiffness. They are essential in manufacturing automotive parts, aerospace frames, and heavy machinery where durability and resistance to deformation are critical. Applications in infrastructure, including bridges and pipelines, rely on rigid materials to maintain stability and ensure long-term performance under varying loads and environmental conditions.

Mechanical Properties: Strength vs Flexibility

Elastic materials exhibit high flexibility by returning to their original shape after deformation, making them ideal for applications requiring resilience and energy absorption. Rigid materials provide superior strength and structural support but have limited flexibility, leading to potential brittleness under stress. The mechanical trade-off between strength and flexibility determines the appropriate material choice for engineering designs demanding durability or adaptability.

Advantages of Using Elastic vs Rigid Components

Elastic components provide superior flexibility and resilience, enabling systems to absorb shocks and accommodate dynamic loads without permanent deformation. Their ability to deform under stress and return to original shape enhances longevity and reduces maintenance costs compared to rigid components. Elastic materials also improve energy efficiency in mechanical applications by minimizing vibrations and dissipating energy more effectively.

Limitations and Challenges of Each Material Type

Elastic materials face limitations in maintaining shape under prolonged or excessive stress, resulting in potential deformation and reduced durability. Rigid materials pose challenges in flexibility and shock absorption, often leading to brittleness and increased risk of fractures under dynamic loads. Both types require careful selection depending on application-specific demands related to strength, elasticity, and fatigue resistance.

Industry Examples: Where Elastic or Rigid Matter Most

Elastic materials, such as rubber and certain polymers, play a critical role in automotive components like tires and engine mounts by providing flexibility and shock absorption essential for performance and safety. Rigid materials, including metals and ceramics, dominate construction and aerospace industries where structural integrity, strength, and durability are paramount for buildings, aircraft frames, and load-bearing parts. In manufacturing, the choice between elastic and rigid materials affects product design, with elastic materials used in seals and gaskets for tight fits and rigid materials preferred in precision machinery and tooling.

Choosing Between Elastic and Rigid for Your Project

Choosing between elastic and rigid materials depends on your project's flexibility and load-bearing requirements. Elastic materials like rubber offer excellent stretch and adaptability, making them ideal for dynamic applications that require shock absorption or shape retention. Rigid materials such as metal or hard plastic provide durability and structural support for applications demanding stability and resistance to deformation.

Elastic Infographic

libterm.com

libterm.com