Non-rigid materials exhibit flexibility and can deform under stress without breaking, making them essential in various applications like robotics, wearable technology, and medical devices. Their unique properties allow for dynamic movement and adaptability, which enhance functionality in environments requiring flexibility and resilience. Explore the rest of the article to understand how non-rigid materials revolutionize modern technology and impact your daily life.

Table of Comparison

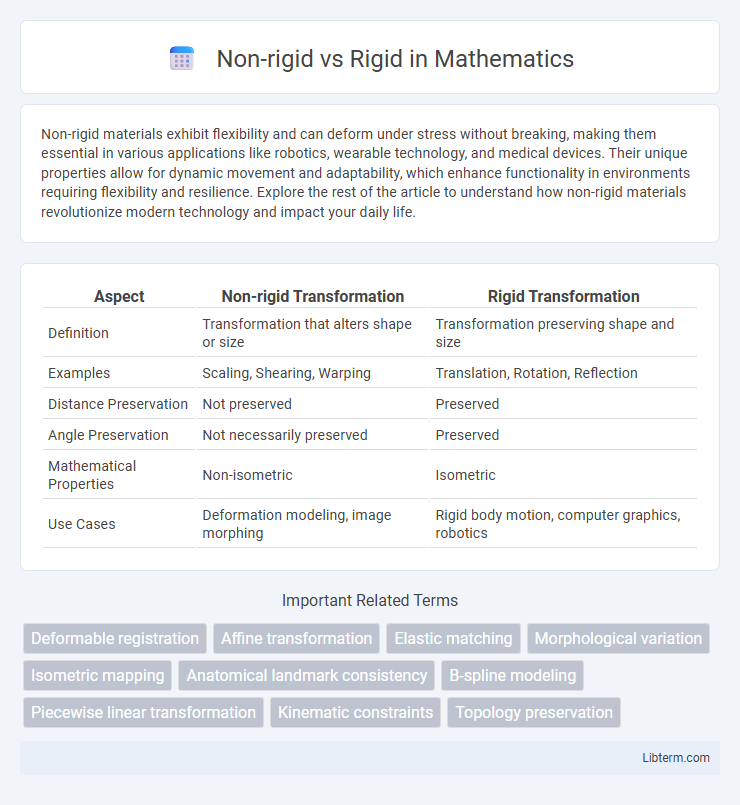

| Aspect | Non-rigid Transformation | Rigid Transformation |

|---|---|---|

| Definition | Transformation that alters shape or size | Transformation preserving shape and size |

| Examples | Scaling, Shearing, Warping | Translation, Rotation, Reflection |

| Distance Preservation | Not preserved | Preserved |

| Angle Preservation | Not necessarily preserved | Preserved |

| Mathematical Properties | Non-isometric | Isometric |

| Use Cases | Deformation modeling, image morphing | Rigid body motion, computer graphics, robotics |

Understanding Rigid and Non-Rigid Concepts

Rigid objects maintain a fixed shape and size under external forces, preserving all internal distances, which is fundamental in classical mechanics and structural engineering. Non-rigid objects deform when subjected to forces, allowing changes in shape and size due to elasticity, plasticity, or fluid dynamics, crucial for understanding soft tissues, flexible materials, and robotics. Differentiating these concepts enables accurate modeling of physical behavior in simulations, material science, and biomechanical applications.

Key Differences Between Rigid and Non-Rigid Systems

Rigid systems maintain a fixed shape and structure, ensuring stability and uniform stress distribution, whereas non-rigid systems allow deformation and flexibility in response to external forces. Rigid systems are primarily designed for static loads, providing predictability in behavior, while non-rigid systems accommodate dynamic loads by absorbing impact and redistributing stress. Material composition, geometric configuration, and load-resistance capacity distinctly differentiate rigid systems, commonly used in structural frameworks, from non-rigid systems applied in flexible engineering designs.

Advantages of Rigid Structures

Rigid structures offer enhanced stability and load-bearing capacity, making them ideal for construction projects requiring durability and resistance to external forces. Their fixed form allows for precise alignment and predictable performance under stress, reducing maintenance costs and increasing safety. The efficiency in distributing weight and minimizing deformation under pressure distinguishes rigid frameworks in engineering applications.

Benefits of Non-Rigid Design

Non-rigid designs offer superior flexibility and adaptability compared to rigid structures, allowing for better accommodation of dynamic forces and environmental changes. This flexibility enhances durability by reducing stress concentrations and preventing material fatigue, which is critical in applications like wearable devices and flexible electronics. Non-rigid designs also enable lightweight construction, improving comfort and mobility in aerospace and automotive industries.

Applications of Rigid Materials

Rigid materials are extensively used in construction due to their high strength and durability, providing structural stability in buildings and bridges. In manufacturing, rigid materials are essential for creating precise and load-bearing components such as gears, frames, and machinery parts. Their resistance to deformation under stress makes them ideal for automotive and aerospace industries, where maintaining shape integrity is critical for safety and performance.

Common Uses of Non-Rigid Materials

Non-rigid materials are widely used in applications requiring flexibility and adaptability, such as inflatable structures, wearable technology, and flexible electronics. These materials enable dynamic shapes and movement, making them ideal for soft robotics, medical devices like prosthetics and orthotics, and packaging solutions. Their ability to deform without breaking contrasts with rigid materials, which are suited for static, load-bearing applications.

Flexibility and Adaptability: Non-Rigid Compared

Non-rigid structures exhibit superior flexibility and adaptability compared to rigid counterparts, allowing them to deform and adjust under varying external forces without permanent damage. This characteristic enables non-rigid systems to absorb shocks and accommodate complex shapes, making them ideal for applications requiring dynamic response and movement. In contrast, rigid structures maintain fixed shapes, offering strength but limited adaptability to changing conditions or environments.

Structural Integrity in Rigid Versus Non-Rigid

Rigid structures maintain superior structural integrity through fixed joints and minimal deformation under stress, offering consistent load distribution and resistance to external forces. Non-rigid structures allow flexibility and movement, which can absorb dynamic loads but may compromise overall stability and increase the risk of deformation. The choice between rigid and non-rigid designs depends on application demands for durability, environmental conditions, and required performance under variable forces.

Cost Implications: Rigid vs Non-Rigid

Rigid materials typically incur higher initial costs due to the need for precise manufacturing, specialized equipment, and complex installation processes. Non-rigid solutions often reduce expenses by offering flexibility, easier handling, and faster installation, which lowers labor costs and minimizes downtime. Long-term maintenance costs tend to be higher for rigid systems because of susceptibility to structural damage, while non-rigid systems provide cost savings through adaptability and repairability.

Choosing Between Rigid and Non-Rigid Solutions

Choosing between rigid and non-rigid solutions depends on the application's flexibility and durability needs. Rigid materials offer strength and stability, ideal for structural components in automotive and aerospace industries, while non-rigid solutions provide adaptability and resilience, suitable for wearable technology and flexible electronics. Evaluating factors like load requirements, environmental conditions, and design complexity ensures optimal performance and longevity.

Non-rigid Infographic

libterm.com

libterm.com