Reboilers and boilers play crucial roles in industrial heating processes, with boilers generating steam or hot water for various applications while reboilers specifically provide heat to distillation columns, ensuring efficient separation of components. Understanding the differences between these systems helps optimize energy use and improve process performance. Explore the rest of the article to discover how your operations can benefit from choosing the right heating solution.

Table of Comparison

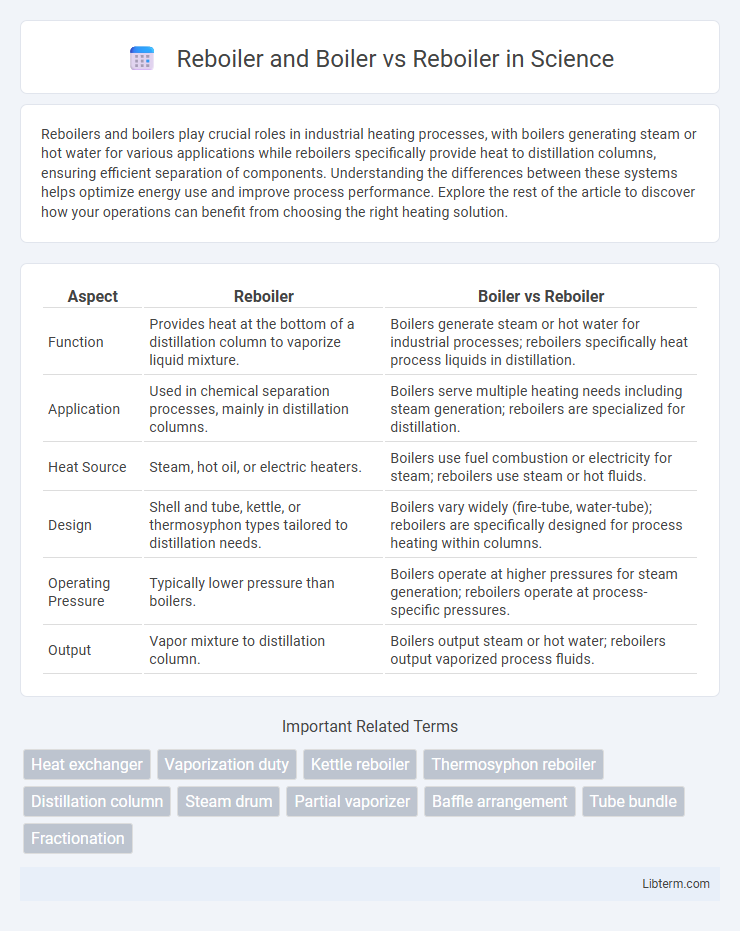

| Aspect | Reboiler | Boiler vs Reboiler |

|---|---|---|

| Function | Provides heat at the bottom of a distillation column to vaporize liquid mixture. | Boilers generate steam or hot water for industrial processes; reboilers specifically heat process liquids in distillation. |

| Application | Used in chemical separation processes, mainly in distillation columns. | Boilers serve multiple heating needs including steam generation; reboilers are specialized for distillation. |

| Heat Source | Steam, hot oil, or electric heaters. | Boilers use fuel combustion or electricity for steam; reboilers use steam or hot fluids. |

| Design | Shell and tube, kettle, or thermosyphon types tailored to distillation needs. | Boilers vary widely (fire-tube, water-tube); reboilers are specifically designed for process heating within columns. |

| Operating Pressure | Typically lower pressure than boilers. | Boilers operate at higher pressures for steam generation; reboilers operate at process-specific pressures. |

| Output | Vapor mixture to distillation column. | Boilers output steam or hot water; reboilers output vaporized process fluids. |

Introduction to Reboilers and Boilers

Reboilers are heat exchangers used primarily in distillation columns to provide the necessary vaporization of the liquid mixture, maintaining the separation process efficiency. Boilers generate steam by heating water and serve as a primary source of thermal energy across various industrial applications, including power generation and heating. The key difference lies in functionality: boilers produce steam for general use, while reboilers specifically support separation processes by supplying heat at the bottom of distillation columns.

Understanding Boiler Functionality

Reboilers play a crucial role in distillation processes by providing heat to vaporize the bottom liquid, enabling effective separation of components. Boilers generate steam or hot water for various industrial applications, focusing on energy production and transfer. Understanding boiler functionality highlights the difference: boilers produce steam for heat and power, whereas reboilers specifically serve to maintain the vaporization necessary in distillation columns.

What is a Reboiler?

A reboiler is a heat exchange device used to generate vapor by boiling a liquid, typically in distillation columns, aiding in the separation process. Unlike a boiler, which produces steam mainly for external applications such as heating or power generation, a reboiler directly supplies heat to a chemical process within the column. Reboilers are integral in maintaining the vapor-liquid equilibrium essential for efficient separation in industries like petrochemical refining and chemical manufacturing.

Key Differences: Boiler vs. Reboiler

A boiler generates steam by heating water to provide power or heat in various industrial processes, while a reboiler specifically supplies heat to the bottom of a distillation column to vaporize the liquid and separate mixtures. Boilers operate under higher pressure and larger scale, typically for steam generation, whereas reboilers function within a distillation setup with precise temperature control to maintain separation efficiency. Key differences include their primary purpose--steam production for boilers versus phase separation for reboilers--and their operational conditions, with boilers handling broader applications and reboilers optimized for targeted chemical processing.

Applications of Boilers in Industry

Boilers serve as essential equipment in industries for generating steam used in power generation, heating, and various manufacturing processes, while reboilers specifically supply heat to distillation columns to facilitate separation of chemical mixtures. Industrial boilers operate across sectors such as energy production, chemical processing, food and beverage, and pharmaceuticals, providing consistent and controlled steam output. Reboilers optimize the efficiency of distillation operations by maintaining proper vaporization rates, complementing the larger-scale steam generation function of boilers in industrial workflows.

Applications of Reboilers in Process Plants

Reboilers play a critical role in process plants by providing the necessary heat to drive separation processes, such as distillation, by vaporizing the bottom liquid in columns. Unlike boilers, which generate steam for various plant utilities, reboilers deliver controlled heat directly to specific process streams, enhancing efficiency and product purity. Their applications span refining, petrochemical, and chemical industries, where they enable precise temperature control and energy integration within distillation and absorption operations.

Types of Reboilers Explained

Reboilers, essential in distillation processes, come in several types including kettle, thermosyphon, forced circulation, and steam heated reboilers, each designed for specific heat transfer and fluid handling requirements. Unlike traditional boilers that generate steam for heating and power, reboilers provide direct heat to the bottom of distillation columns to vaporize the liquid mixture, enhancing separation efficiency. Understanding the distinct functions and mechanisms of reboilers versus boilers is crucial for selecting the appropriate equipment in chemical processing industries.

Efficiency Considerations: Boiler and Reboiler

Reboilers improve process efficiency by precisely controlling vapor-liquid separation, often resulting in lower energy consumption compared to boilers due to targeted heat transfer. Boilers generate steam for broad heat applications with higher fuel usage, whereas reboilers utilize existing process streams for efficient heat recovery. Optimizing reboiler design enhances thermal efficiency, minimizes operational costs, and reduces environmental impact relative to conventional boiler systems.

Common Challenges and Maintenance Tips

Reboilers and boilers often face common challenges such as scaling, fouling, and corrosion, which reduce heat transfer efficiency and operational reliability. Effective maintenance strategies include regular inspection, timely cleaning, and monitoring of temperature and pressure to prevent tube leaks and ensure optimal performance. Implementing predictive maintenance using sensors and automated controls helps minimize downtime and extend equipment lifespan in both reboilers and boilers.

Choosing Between Boiler and Reboiler: Factors to Consider

Selecting between a boiler and a reboiler depends primarily on the process requirements for heat transfer and fluid phase separation. Boilers generate steam or hot water for facility-wide heating, relying on combustion or electric heating, while reboilers specifically provide heat to distillation columns to separate liquid mixtures by vaporizing components at controlled temperatures. Key factors include thermal load capacity, operational control precision, space constraints, and integration with existing systems, with reboilers favored for targeted process heating and boilers suited for broader utility steam production.

Reboiler and Boiler Infographic

libterm.com

libterm.com