Outsourcing allows businesses to delegate non-core tasks to specialized external providers, resulting in cost savings and increased operational efficiency. By leveraging global talent pools, companies can access expertise and technologies that may not be available in-house. Discover how outsourcing can transform your business strategies and drive growth in the full article.

Table of Comparison

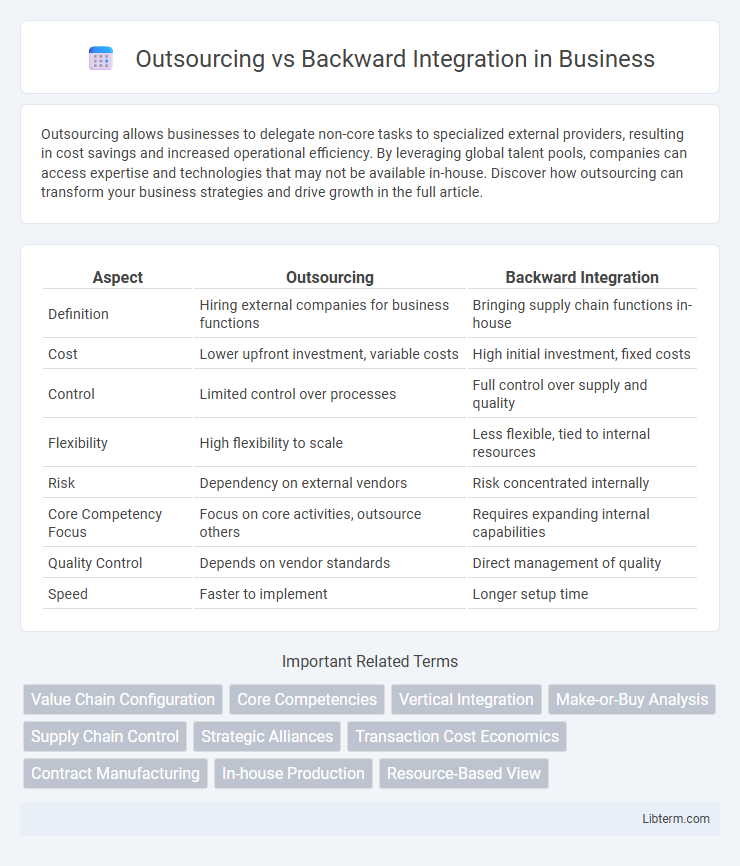

| Aspect | Outsourcing | Backward Integration |

|---|---|---|

| Definition | Hiring external companies for business functions | Bringing supply chain functions in-house |

| Cost | Lower upfront investment, variable costs | High initial investment, fixed costs |

| Control | Limited control over processes | Full control over supply and quality |

| Flexibility | High flexibility to scale | Less flexible, tied to internal resources |

| Risk | Dependency on external vendors | Risk concentrated internally |

| Core Competency Focus | Focus on core activities, outsource others | Requires expanding internal capabilities |

| Quality Control | Depends on vendor standards | Direct management of quality |

| Speed | Faster to implement | Longer setup time |

Introduction: Understanding Outsourcing and Backward Integration

Outsourcing involves delegating specific business processes or functions to external specialists to reduce costs and focus on core competencies. Backward integration refers to a company's strategy of acquiring or merging with suppliers to control the supply chain and improve operational efficiency. Both strategies play crucial roles in optimizing production, cost management, and competitive advantage within supply chain management.

Definition and Concepts: Outsourcing vs Backward Integration

Outsourcing refers to the strategic practice where a company delegates specific business processes or services to external suppliers to reduce costs and enhance efficiency. Backward integration involves a company expanding its operations by acquiring or controlling its suppliers to gain more control over the supply chain and reduce dependency. These contrasting approaches represent different strategies for managing production and supply chain activities, with outsourcing focusing on external collaboration and backward integration emphasizing internal control.

Key Differences Between Outsourcing and Backward Integration

Outsourcing involves contracting external firms to handle specific business functions, enabling cost reduction and access to specialized skills, whereas backward integration refers to a company acquiring or merging with its suppliers to control its supply chain and reduce dependency. Key differences include the level of operational control--outsourcing relinquishes direct oversight, while backward integration increases control over production processes. Financially, outsourcing typically lowers initial investment, whereas backward integration requires significant capital but can lead to long-term cost savings and improved supply chain stability.

Advantages of Outsourcing

Outsourcing offers companies cost savings by leveraging external suppliers with specialized expertise and economies of scale, reducing the need for capital investment in production facilities. It enhances flexibility, allowing businesses to quickly scale operations up or down in response to market demand without long-term commitments. Access to global talent and advanced technologies through outsourcing enables firms to improve product quality and accelerate time-to-market.

Benefits of Backward Integration

Backward integration enhances supply chain control by allowing companies to directly manage raw material sources and production processes, reducing dependency on external suppliers. This strategy improves cost efficiency through the elimination of supplier margins and better coordination, leading to higher profit margins. Firms benefit from increased product quality control and faster response times to market changes, strengthening competitive advantage and long-term sustainability.

Risks and Challenges of Outsourcing

Outsourcing carries risks such as loss of control over critical processes, potential quality issues, and dependency on third-party vendors, which can lead to disruptions if the supplier fails to meet expectations. Data security and confidentiality pose significant challenges, especially when sensitive information is handled externally. Managing communication barriers and aligning objectives between the company and outsourcing partners requires continuous oversight to mitigate risks effectively.

Drawbacks of Backward Integration

Backward integration can lead to increased operational complexity and higher capital expenditure, as companies must invest in manufacturing facilities and supply chain management. It may reduce flexibility by locking firms into specific suppliers or technologies, making adaptation to market changes more difficult. Furthermore, backward integration can cause inefficiencies if the company lacks expertise in upstream processes, potentially resulting in higher production costs compared to specialized suppliers.

Strategic Considerations for Businesses

Strategic considerations for businesses choosing between outsourcing and backward integration involve assessing cost efficiency, control over supply chains, and risk management. Outsourcing offers flexibility and access to specialized expertise, reducing capital investment, while backward integration enhances control over quality, inventory, and production timelines. Evaluating market dynamics, core competencies, and long-term growth objectives is critical for aligning the chosen approach with the company's strategic goals.

Real-World Examples: Success Stories and Failures

Apple's outsourcing strategy, particularly with Foxconn for manufacturing, highlights a successful model of cost efficiency and focus on core competencies, while Tesla's backward integration by producing batteries in-house demonstrates control over quality and supply chain resilience. In contrast, Boeing's heavy reliance on outsourcing led to the 737 MAX delays and safety issues, exposing risks in over-dependence on external suppliers. Meanwhile, Zara's backward integration in its supply chain has enabled rapid response to fashion trends, contrasting with the failures of companies like Kodak that resisted outsourcing and innovation.

Choosing the Right Approach for Your Business

Choosing between outsourcing and backward integration depends on your business goals, cost structure, and control preferences. Outsourcing offers flexibility, reduced capital investment, and access to specialized expertise, while backward integration provides greater control over quality, supply chain reliability, and potential cost savings through internalization. Assessing factors such as market conditions, production complexity, and long-term strategic objectives is crucial to determine the optimal approach for operational efficiency and competitive advantage.

Outsourcing Infographic

libterm.com

libterm.com