Vertical integration enhances your business control by merging multiple stages of production or distribution under one company, reducing costs and increasing efficiency. It strengthens supply chain coordination and improves competitive advantage by streamlining processes and limiting dependency on external suppliers. Discover how vertical integration can transform your business operations and strategy in the rest of this article.

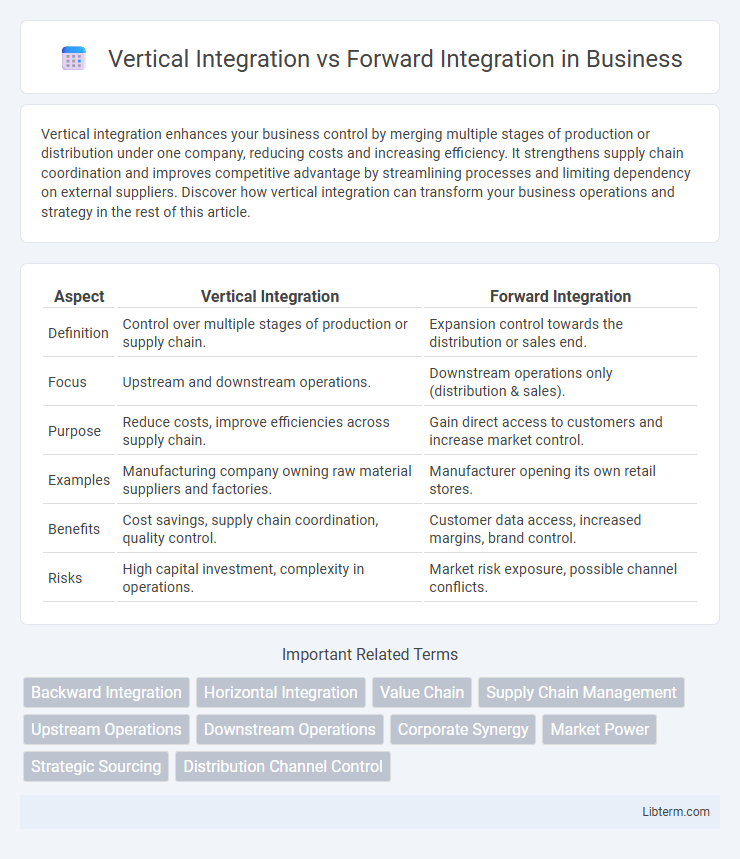

Table of Comparison

| Aspect | Vertical Integration | Forward Integration |

|---|---|---|

| Definition | Control over multiple stages of production or supply chain. | Expansion control towards the distribution or sales end. |

| Focus | Upstream and downstream operations. | Downstream operations only (distribution & sales). |

| Purpose | Reduce costs, improve efficiencies across supply chain. | Gain direct access to customers and increase market control. |

| Examples | Manufacturing company owning raw material suppliers and factories. | Manufacturer opening its own retail stores. |

| Benefits | Cost savings, supply chain coordination, quality control. | Customer data access, increased margins, brand control. |

| Risks | High capital investment, complexity in operations. | Market risk exposure, possible channel conflicts. |

Understanding Vertical and Forward Integration

Vertical integration involves a company expanding its control over multiple stages of the production or supply chain, from raw materials to finished products, enhancing operational efficiency and reducing costs. Forward integration specifically refers to a firm moving closer to the end customer by acquiring or developing distribution channels, retail outlets, or direct sales capabilities to increase market control and improve customer access. Understanding these strategies helps businesses optimize supply chain management and competitive positioning by choosing whether to control upstream suppliers or downstream distribution processes.

Key Differences Between Vertical and Forward Integration

Vertical integration involves a company expanding its operations into different stages of production within the same supply chain, including both upstream suppliers and downstream distributors. Forward integration specifically refers to a company moving closer to the end customer by controlling distribution channels or retail outlets. Key differences include scope--vertical integration covers both upstream and downstream activities, while forward integration focuses solely on downstream control to increase market presence and customer access.

Benefits of Vertical Integration for Businesses

Vertical integration enhances businesses by reducing supply chain costs and improving control over production quality, resulting in increased operational efficiency. By owning multiple stages of the supply chain, companies can secure reliable sources of raw materials and optimize inventory management, leading to faster time-to-market. This strategic control also strengthens competitive advantage through improved coordination and reduced dependence on external suppliers or distributors.

Advantages of Forward Integration

Forward integration enables companies to gain direct control over their distribution channels, enhancing supply chain efficiency and reducing dependency on intermediaries. This strategy improves profit margins by capturing retail or customer-facing margins and fosters stronger customer relationships through better market feedback and tailored services. By controlling the downstream process, firms can enhance brand loyalty, increase market share, and respond more swiftly to consumer demand.

Potential Challenges of Vertical and Forward Integration

Vertical integration poses potential challenges such as increased operational complexity and higher capital requirements, which may strain a company's financial resources and management capacity. Forward integration often faces obstacles related to market resistance, increased competition with downstream partners, and the need for strong customer relationship management. Both strategies require substantial investment in supply chain coordination and risk exposure to demand fluctuations across multiple stages of production and distribution.

Industry Examples of Vertical Integration

Vertical integration involves a company expanding its operations into different stages of production within the same industry, such as Tesla manufacturing batteries and assembling electric vehicles to control the supply chain. Forward integration occurs when a manufacturer takes control over distribution or retail, similar to Apple operating its own retail stores to sell products directly to consumers. Industry examples of vertical integration include Amazon owning warehouses and delivery services, and Zara controlling both design and retail outlets to streamline fashion production.

Case Studies on Forward Integration Success

Forward integration, a growth strategy where companies move closer to the end customer by owning distribution or retail outlets, has shown remarkable success in case studies like Apple's direct retail stores and Tesla's owned showrooms, enhancing control over customer experience and brand presentation. Brands such as Starbucks also exemplify forward integration by expanding their company-operated stores, which resulted in increased profit margins and stronger customer loyalty. These case studies underscore forward integration's potential to improve market responsiveness, supply chain efficiencies, and overall competitive advantage.

Strategic Considerations Before Choosing Integration

Companies must evaluate market control and cost efficiencies when choosing between vertical integration and forward integration, considering how each approach impacts supply chain management and customer access. Strategic considerations include assessing the risks of increased operational complexity against potential gains in market power and margin enhancement. Analyzing competitive dynamics, resource capabilities, and long-term scalability ensures integration aligns with overall corporate objectives and growth strategies.

Impact on Supply Chain and Competitive Advantage

Vertical integration enhances control over the entire supply chain by owning multiple production or distribution stages, reducing dependency on external suppliers and minimizing disruptions. Forward integration shifts a company closer to the end customer by acquiring or developing distribution channels, improving customer experience and market responsiveness. Both strategies increase competitive advantage by enabling cost efficiencies, improving quality control, and creating barriers to entry for competitors.

Future Trends in Business Integration Strategies

Future trends in business integration strategies emphasize increased adoption of vertical integration to gain tighter control over supply chains, enhance cost efficiency, and ensure quality consistency. Forward integration is projected to evolve with businesses leveraging digital platforms and direct-to-consumer models to expand market reach and improve customer experience. The convergence of advanced technologies such as AI, IoT, and blockchain will drive smarter decision-making and seamless coordination across both vertical and forward integration processes.

Vertical Integration Infographic

libterm.com

libterm.com