Lean Management streamlines business processes by eliminating waste and enhancing efficiency, resulting in higher productivity and better customer satisfaction. It focuses on continuous improvement, empowering teams to identify inefficiencies and optimize workflows. Discover how adopting Lean Management can transform your organization by reading the full article.

Table of Comparison

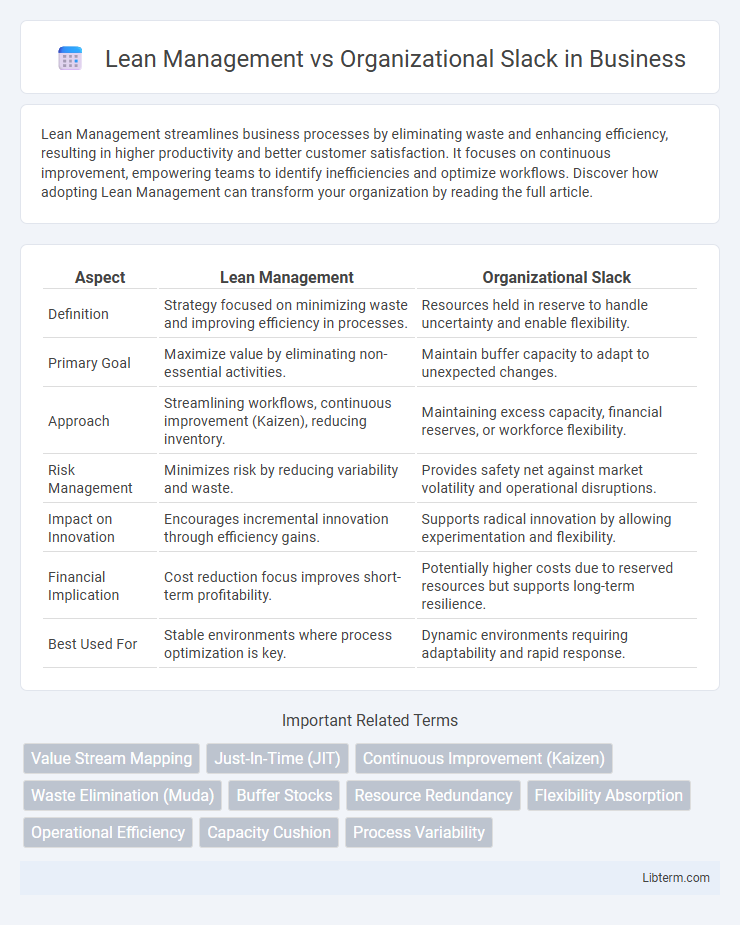

| Aspect | Lean Management | Organizational Slack |

|---|---|---|

| Definition | Strategy focused on minimizing waste and improving efficiency in processes. | Resources held in reserve to handle uncertainty and enable flexibility. |

| Primary Goal | Maximize value by eliminating non-essential activities. | Maintain buffer capacity to adapt to unexpected changes. |

| Approach | Streamlining workflows, continuous improvement (Kaizen), reducing inventory. | Maintaining excess capacity, financial reserves, or workforce flexibility. |

| Risk Management | Minimizes risk by reducing variability and waste. | Provides safety net against market volatility and operational disruptions. |

| Impact on Innovation | Encourages incremental innovation through efficiency gains. | Supports radical innovation by allowing experimentation and flexibility. |

| Financial Implication | Cost reduction focus improves short-term profitability. | Potentially higher costs due to reserved resources but supports long-term resilience. |

| Best Used For | Stable environments where process optimization is key. | Dynamic environments requiring adaptability and rapid response. |

Introduction to Lean Management and Organizational Slack

Lean Management emphasizes maximizing value by minimizing waste and streamlining processes through continuous improvement and efficient resource utilization. Organizational Slack refers to the excess resources or capacity available beyond current operational requirements, providing a cushion for adaptation and innovation. Balancing Lean Management's pursuit of efficiency with adequate Organizational Slack is critical for sustaining flexibility and resilience in dynamic business environments.

Core Principles of Lean Management

Lean Management centers on maximizing value by minimizing waste, emphasizing continuous improvement, and enhancing efficiency through just-in-time production and employee empowerment. Organizational Slack refers to the excess resources or buffer capacity maintained to absorb variability and foster innovation. While Lean Management drives strict resource optimization and waste elimination, slack provides flexibility and resilience, highlighting a strategic balance between streamlined operations and maintaining adaptive capacity.

Understanding Organizational Slack

Organizational slack refers to the surplus resources within a company that provide a buffer for innovation, adaptation, and risk-taking, contrasting with lean management's focus on minimizing waste and maximizing efficiency. Understanding organizational slack is crucial as it enables firms to maintain flexibility and resilience in volatile markets by allocating excess capacity for strategic initiatives. Balancing lean practices with sufficient slack ensures sustainable performance without sacrificing agility or the ability to explore new opportunities.

Key Differences Between Lean Management and Organizational Slack

Lean Management emphasizes eliminating waste and improving efficiency by streamlining processes and maximizing resource utilization. Organizational Slack involves maintaining excess resources or capacity to absorb shocks and uncertainties, prioritizing flexibility over strict efficiency. The key difference lies in Lean Management's goal of minimal redundancy versus Organizational Slack's focus on preserving buffer resources for adaptability and risk management.

Advantages of Lean Management

Lean Management enhances operational efficiency by eliminating waste, reducing costs, and optimizing resource utilization. It fosters continuous improvement and agility, enabling organizations to respond swiftly to market changes and customer demands. Unlike organizational slack, which maintains excess capacity as a buffer, Lean Management drives maximum productivity and value creation with minimal resource redundancy.

Benefits and Risks of Organizational Slack

Organizational slack, characterized by excess resources and flexibility, provides a buffer that enhances innovation capacity and resilience during market fluctuations, which complements lean management's efficiency focus. However, excessive slack can lead to resource wastage, reduced urgency, and complacency, undermining lean principles aimed at eliminating inefficiencies. Balancing organizational slack ensures sustained adaptability without sacrificing lean goals of cost reduction and streamlined operations.

Impact on Innovation and Agility

Lean Management emphasizes minimizing waste and optimizing processes, which enhances agility by streamlining workflows and accelerating decision-making. Organizational Slack provides a buffer of resources and time that fosters innovation by allowing experimentation and risk-taking without immediate pressures. Balancing Lean practices with sufficient slack enables companies to maintain operational efficiency while nurturing creative problem-solving and adaptive capacity.

Case Studies: Lean Management vs Organizational Slack

Case studies comparing Lean Management and Organizational Slack reveal that Lean strategies prioritize waste reduction and continuous improvement to enhance efficiency, while Organizational Slack emphasizes resource buffers for flexibility and innovation. In manufacturing sectors, Lean Management implementations have demonstrated significant cost savings and productivity gains by minimizing excess inventory and streamlining processes. Conversely, technology firms employing Organizational Slack find that maintaining extra capacity and slack resources supports rapid adaptation and fosters creativity during market uncertainties.

Integrating Lean Practices with Controlled Slack

Integrating Lean Management with controlled organizational slack enhances operational efficiency while maintaining necessary flexibility for innovation and problem-solving. Lean practices focus on eliminating waste and optimizing value streams, whereas strategic slack provides a buffer to absorb variability and support adaptive capacity. Balancing lean methodologies with measured slack allocation fosters agility and resilience, enabling sustained performance improvement in dynamic business environments.

Choosing the Right Approach for Your Organization

Selecting between Lean Management and Organizational Slack hinges on your organization's goals for efficiency and innovation balance. Lean Management emphasizes minimizing waste and optimizing processes to enhance productivity and cost-effectiveness, ideal for companies targeting operational excellence. Organizational Slack, by maintaining excess resources, fosters flexibility and resilience, supporting innovation and adaptability in dynamic markets.

Lean Management Infographic

libterm.com

libterm.com