Technical efficiency measures how well resources are used to produce outputs without waste, reflecting operational effectiveness in processes. Improving technical efficiency can reduce costs, enhance productivity, and boost overall performance in various industries. Discover practical strategies to optimize technical efficiency and elevate your organization's success in the full article.

Table of Comparison

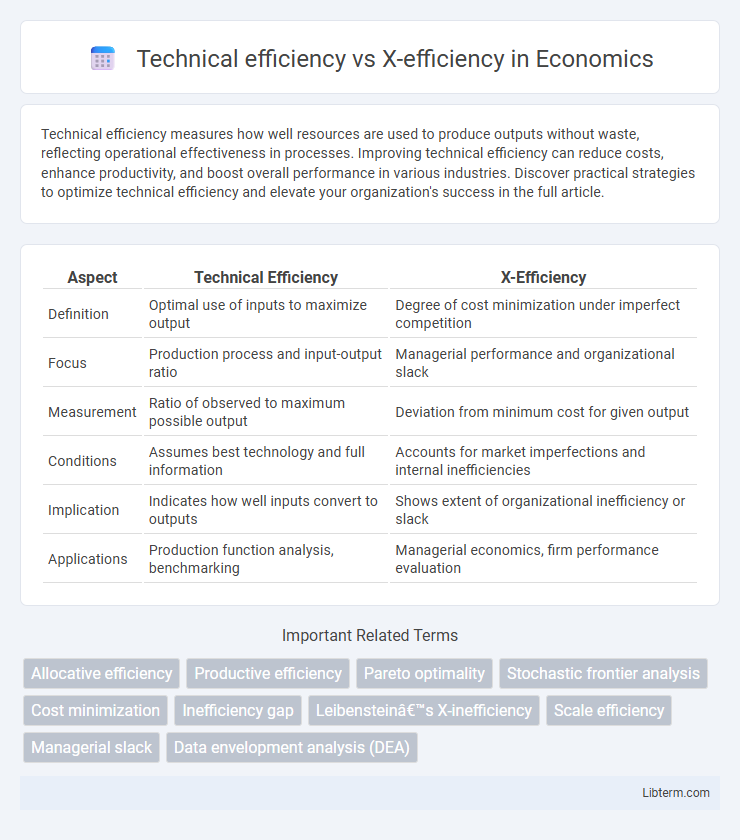

| Aspect | Technical Efficiency | X-Efficiency |

|---|---|---|

| Definition | Optimal use of inputs to maximize output | Degree of cost minimization under imperfect competition |

| Focus | Production process and input-output ratio | Managerial performance and organizational slack |

| Measurement | Ratio of observed to maximum possible output | Deviation from minimum cost for given output |

| Conditions | Assumes best technology and full information | Accounts for market imperfections and internal inefficiencies |

| Implication | Indicates how well inputs convert to outputs | Shows extent of organizational inefficiency or slack |

| Applications | Production function analysis, benchmarking | Managerial economics, firm performance evaluation |

Introduction to Technical Efficiency and X-Efficiency

Technical efficiency measures a firm's ability to maximize output from a given set of inputs, reflecting optimal production processes under perfect information and competitive markets. X-efficiency, introduced by economist Harvey Leibenstein, captures deviations from technical efficiency due to organizational slack, lack of competitive pressure, or managerial inefficiencies. Understanding the distinction between technical efficiency and X-efficiency highlights how firms operate below their potential output because of internal inefficiencies and market imperfections.

Defining Technical Efficiency

Technical efficiency measures a firm's ability to maximize output from a given set of inputs, reflecting optimal resource utilization in production. It is benchmarked against the best-performing firms producing the highest output with minimal input, indicating no waste in the production process. Technical efficiency contrasts with X-efficiency, which accounts for inefficiencies due to organizational slack or managerial performance beyond pure resource allocation.

Understanding X-Efficiency

X-efficiency measures how well a firm utilizes its resources under conditions of imperfect competition, reflecting internal efficiency beyond the traditional concept of technical efficiency, which assesses the maximum output from given inputs. Unlike technical efficiency, X-efficiency considers organizational factors such as motivation, management practices, and operational slack that affect productivity within a firm. Understanding X-efficiency helps explain variations in firm performance that cannot be accounted for by technology or resource availability alone.

Key Differences Between Technical Efficiency and X-Efficiency

Technical efficiency measures how well inputs are converted into outputs under optimal conditions, indicating the maximum output achievable with given resources. X-efficiency, however, reflects the actual output relative to the potential output, capturing inefficiencies due to lack of competitive pressure or organizational slack. Key differences include technical efficiency's basis on production possibility frontiers versus X-efficiency's focus on internal operational performance and managerial effectiveness.

Measuring Technical Efficiency in Practice

Measuring technical efficiency involves assessing the maximum output a firm can produce from given inputs using data envelopment analysis (DEA) or stochastic frontier analysis (SFA) to identify deviations from the production frontier. X-efficiency focuses on the extent to which firms minimize inefficiencies within their operations, often influenced by managerial performance and organizational discipline. Practical measurement of technical efficiency requires accurate data on input quantities and output levels, coupled with robust econometric models to differentiate between random errors and inefficiency effects.

Factors Influencing X-Efficiency in Organizations

X-efficiency in organizations is influenced by factors such as managerial motivation, organizational culture, and employee incentives, which directly impact the effective utilization of resources beyond technical efficiency measures. Unlike technical efficiency, which focuses on optimal input-output ratios, X-efficiency addresses the degree of slack or waste due to internal inefficiencies, including motivational and behavioral aspects. Improved communication, strong leadership, and performance-based reward systems enhance X-efficiency by minimizing resource wastage and fostering a productive workplace environment.

Impacts of Inefficiency on Output and Costs

Technical efficiency measures the maximum possible output from given inputs under optimal conditions, while X-efficiency reflects the actual output produced considering organizational inefficiencies. Inefficiency in technical efficiency typically results from suboptimal resource utilization, causing lower output and higher production costs. X-inefficiency increases costs further by revealing inefficiencies in management and incentives, leading to output levels below potential and escalating operational expenses.

Role of Management in Reducing X-Inefficiency

Technical efficiency measures the optimal use of resources to produce maximum output, whereas X-efficiency reflects the actual productivity level within an organization, often hindered by managerial inefficiencies and organizational slack. Effective management reduces X-inefficiency by implementing strong performance monitoring, fostering employee motivation, and streamlining processes to minimize resource wastage. By emphasizing accountability and continuous improvement, managers can bridge the gap between potential and actual output, enhancing overall organizational efficiency.

Case Studies: Technical Efficiency vs X-Efficiency Analyses

Case studies on technical efficiency often evaluate firms based on their ability to maximize output from given inputs using methods like Data Envelopment Analysis (DEA) or Stochastic Frontier Analysis (SFA). In contrast, X-efficiency analyses focus on managerial effectiveness and internal organizational behavior that explain discrepancies between best practice frontiers and actual performance, as seen in studies of the manufacturing sector and banking industries. Comparative research highlights that technical efficiency metrics capture input-output optimization, whereas X-efficiency measures reveal organizational slack, emphasizing the importance of addressing both dimensions for productivity improvements.

Strategies to Enhance Overall Organizational Efficiency

Technical efficiency involves maximizing output from given inputs, emphasizing streamlined processes and resource optimization through methods such as lean manufacturing and automation. X-efficiency addresses minimizing inefficiencies due to organizational behavior, promoting motivation, improved management practices, and competitive pressure to reduce slack and enhance productivity. Integrating advanced data analytics with employee engagement programs and continuous process improvement strategies drives overall organizational efficiency by balancing technical capabilities with human factors.

Technical efficiency Infographic

libterm.com

libterm.com