A resolver is an electromagnetic device used to measure angular position and velocity, commonly found in industrial automation and aerospace applications for precise motion control. Its robust construction allows accurate feedback in harsh environments where optical encoders might fail. Discover how understanding your resolver's functionality can enhance your systems by reading the full article.

Table of Comparison

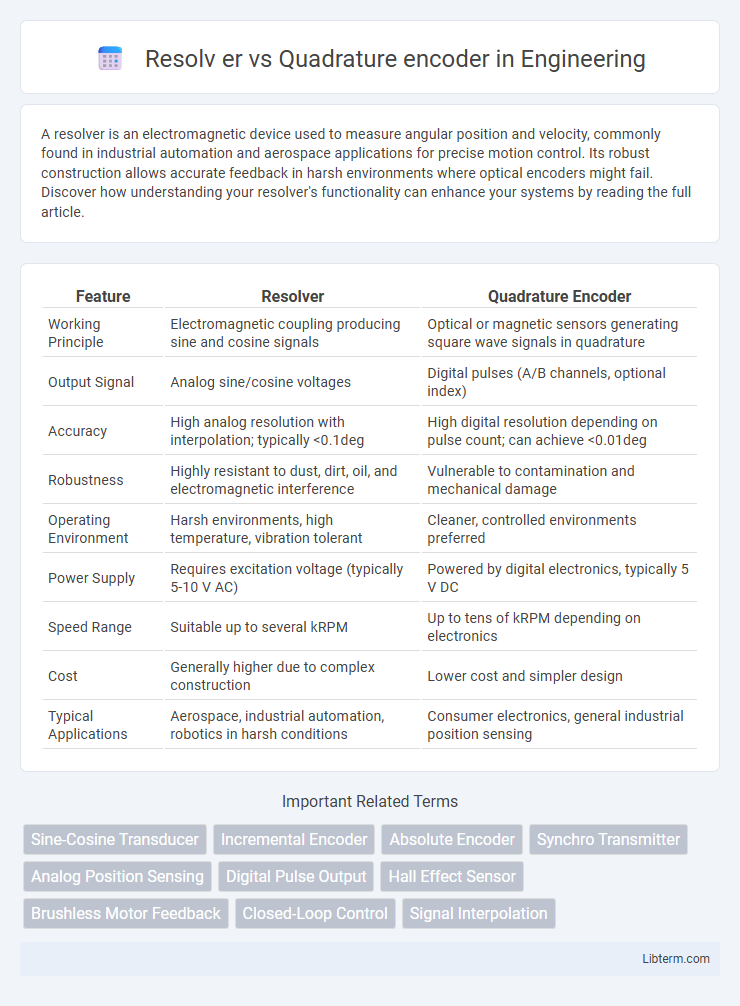

| Feature | Resolver | Quadrature Encoder |

|---|---|---|

| Working Principle | Electromagnetic coupling producing sine and cosine signals | Optical or magnetic sensors generating square wave signals in quadrature |

| Output Signal | Analog sine/cosine voltages | Digital pulses (A/B channels, optional index) |

| Accuracy | High analog resolution with interpolation; typically <0.1deg | High digital resolution depending on pulse count; can achieve <0.01deg |

| Robustness | Highly resistant to dust, dirt, oil, and electromagnetic interference | Vulnerable to contamination and mechanical damage |

| Operating Environment | Harsh environments, high temperature, vibration tolerant | Cleaner, controlled environments preferred |

| Power Supply | Requires excitation voltage (typically 5-10 V AC) | Powered by digital electronics, typically 5 V DC |

| Speed Range | Suitable up to several kRPM | Up to tens of kRPM depending on electronics |

| Cost | Generally higher due to complex construction | Lower cost and simpler design |

| Typical Applications | Aerospace, industrial automation, robotics in harsh conditions | Consumer electronics, general industrial position sensing |

Introduction to Resolvers and Quadrature Encoders

Resolvers are analog rotary position sensors that use electromagnetic induction to provide absolute angle measurements with high accuracy and reliability in harsh environments. Quadrature encoders are digital optical or magnetic sensors that generate two pulse signals 90 degrees out of phase, allowing precise measurement of rotational position, speed, and direction. Both devices are essential for motion control applications, with resolvers offering robustness and absolute position feedback, while quadrature encoders deliver high resolution and ease of integration in electronic systems.

Working Principle of Resolvers

Resolvers operate on the principle of electromagnetic induction, using a rotor and stator arrangement where the rotor carries an AC excitation signal that induces voltages in the stator windings proportional to the sine and cosine of the rotor angle. This analog signal output enables precise measurement of angular position and velocity, making resolvers highly robust in harsh environments with electrical noise and temperature variations. In contrast, quadrature encoders generate digital pulse signals based on optical or magnetic sensors detecting shaft rotation, providing discrete position feedback rather than continuous analog signals.

How Quadrature Encoders Operate

Quadrature encoders operate by utilizing two output signals, typically labeled A and B, which are phase-shifted by 90 degrees to detect both the position and direction of rotation. These two channels generate pulses that, when interpreted, provide precise information about angular displacement and speed, allowing for accurate motion control. Signal processing of the quadrature output determines the increment or decrement of the position count, enabling bidirectional tracking essential in robotics and automation systems.

Key Differences Between Resolvers and Quadrature Encoders

Resolvers use analog signals and sinusoidal outputs to provide absolute position feedback, making them highly robust in harsh environments and resistant to electrical noise. Quadrature encoders generate digital pulse signals with incremental position information, offering high resolution and easy interface with digital systems but requiring a reference position to determine absolute position. Unlike resolvers, quadrature encoders are more sensitive to contaminants and mechanical wear, impacting long-term reliability in demanding applications.

Accuracy and Resolution Comparison

Resolvers provide robust angular position sensing with moderate resolution, typically offering accuracy around +-10 arc-minutes and resolution limited by their analog nature. Quadrature encoders achieve higher resolution and accuracy, often reaching sub-arcminute precision with digital pulse counts exceeding thousands lines per revolution. The digital output of quadrature encoders enables precise position feedback, whereas resolvers excel in harsh environments due to their noise immunity and robustness despite lower resolution.

Environmental Robustness and Reliability

Resolvers offer superior environmental robustness due to their inherent construction with rotary transformers and lack of electronic components, enabling reliable operation under extreme temperatures, vibrations, moisture, and electromagnetic interference. Quadrature encoders, while providing high resolution and precision, are more susceptible to dust, dirt, and electrical noise, which can compromise their performance and reliability in harsh environments. Industries requiring high reliability under challenging conditions, such as aerospace and military applications, often prefer resolvers for their durability and consistent signal generation.

Applications of Resolvers in Industry

Resolvers are widely used in industrial automation for precise angular position and speed sensing in harsh environments, including robotics, aerospace, and electric motor control systems. Their robustness to extreme temperatures, vibrations, and electromagnetic interference makes them ideal for applications such as aerospace navigation systems, CNC machine tools, and electric vehicle motor feedback. Resolvers provide reliable real-time feedback in critical control systems where accuracy and durability are paramount.

Common Uses for Quadrature Encoders

Quadrature encoders are commonly used in robotics, CNC machines, and industrial automation for precise position and speed feedback. They provide reliable incremental signals that enable accurate tracking of rotational movement in motor control systems and encoder-based feedback loops. These encoders are essential in applications requiring fine resolution and real-time monitoring of shaft position and direction.

Cost and Maintenance Factors

Resolvers typically have higher initial costs due to their robust construction and ability to operate in extreme environments, making them suitable for heavy-duty industrial applications. Quadrature encoders are generally more cost-effective upfront but may incur increased maintenance expenses over time because of their sensitivity to dust, moisture, and mechanical wear. Maintenance for resolvers tends to be lower due to their rugged design and fewer moving parts, contributing to long-term reliability and reduced downtime costs compared to quadrature encoders.

Choosing Between Resolver and Quadrature Encoder

Choosing between a resolver and a quadrature encoder depends heavily on application requirements such as environment, accuracy, and durability. Resolvers excel in harsh conditions with high vibration, temperature, and electrical noise, offering robust absolute position feedback without susceptibility to signal interference. Quadrature encoders provide higher resolution and more precise incremental position data, making them ideal for applications demanding fine motion control and easy digital integration.

Resolv er Infographic

libterm.com

libterm.com