Consignment stock allows you to store inventory at your location without ownership until it's used or sold, improving cash flow and reducing holding costs. This strategy enhances supply chain efficiency by minimizing stockouts and optimizing replenishment cycles. Explore the rest of the article to understand how consignment stock can benefit your business operations.

Table of Comparison

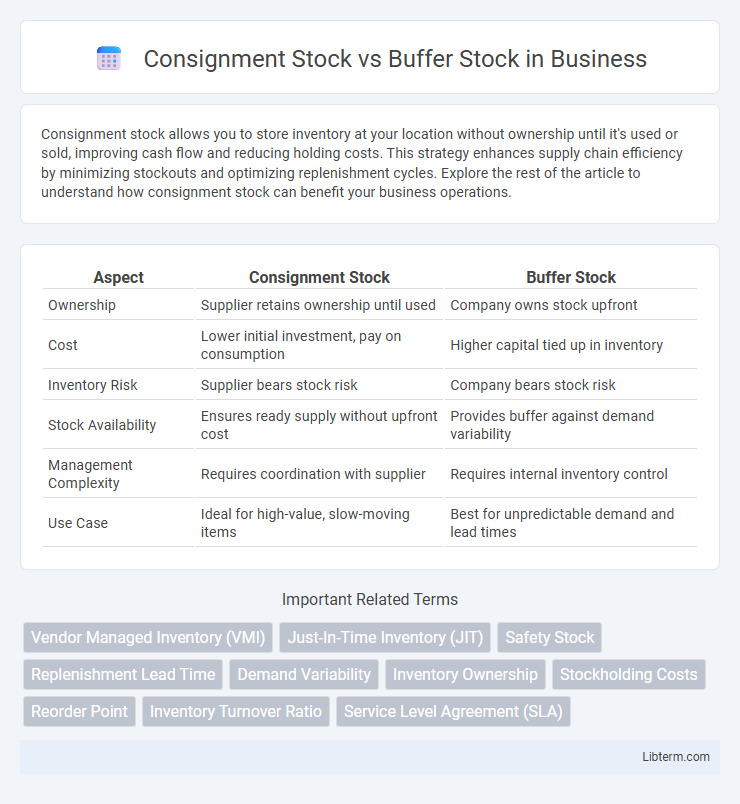

| Aspect | Consignment Stock | Buffer Stock |

|---|---|---|

| Ownership | Supplier retains ownership until used | Company owns stock upfront |

| Cost | Lower initial investment, pay on consumption | Higher capital tied up in inventory |

| Inventory Risk | Supplier bears stock risk | Company bears stock risk |

| Stock Availability | Ensures ready supply without upfront cost | Provides buffer against demand variability |

| Management Complexity | Requires coordination with supplier | Requires internal inventory control |

| Use Case | Ideal for high-value, slow-moving items | Best for unpredictable demand and lead times |

Introduction to Consignment Stock and Buffer Stock

Consignment stock refers to inventory owned by a supplier but stored at the buyer's premises, allowing the buyer to use goods without immediate payment until they are consumed. Buffer stock, also known as safety stock, is extra inventory held to prevent stockouts caused by demand fluctuations or supply chain delays. Both strategies optimize inventory management by balancing availability and cost, with consignment stock reducing capital tied up in inventory and buffer stock providing a safeguard against uncertainty.

Key Differences Between Consignment Stock and Buffer Stock

Consignment stock is inventory owned by the supplier but held at the buyer's location, reducing the buyer's capital investment and risk, while buffer stock is extra inventory maintained by the buyer to prevent stockouts during demand fluctuations or supply delays. Key differences include ownership--consignment stock remains the supplier's property until used, whereas buffer stock is owned by the buyer--and purpose, with consignment stock aimed at supply chain efficiency and buffer stock focused on demand uncertainty mitigation. Consignment stock typically involves supplier-managed inventory visibility, whereas buffer stock demands accurate demand forecasting and inventory control by the buyer.

How Consignment Stock Works

Consignment stock involves goods stored at the buyer's location but owned by the supplier until consumed, enabling reduced inventory costs and improved cash flow for the buyer. The supplier maintains ownership, monitoring stock levels and replenishing inventory as needed based on actual consumption data. This system enhances supply chain efficiency by minimizing stockouts and optimizing inventory turnover without upfront purchasing.

How Buffer Stock Functions

Buffer stock functions as a strategic reserve of inventory maintained by a company to absorb demand fluctuations and supply chain uncertainties, ensuring uninterrupted production and customer fulfillment. Unlike consignment stock, which is owned by the supplier and stored at the buyer's location, buffer stock is owned and controlled by the company itself, providing immediate availability for internal use. This stock acts as a safeguard against delays in procurement, sudden spikes in demand, and supply disruptions, thereby stabilizing operational efficiency and minimizing stockouts.

Advantages of Consignment Stock

Consignment stock reduces inventory holding costs for the buyer by keeping goods owned by the supplier until used or sold, improving cash flow management. It enhances supply chain flexibility and reduces stockouts by enabling timely replenishment without upfront investment. Suppliers benefit from better market insight and demand forecasting through real-time inventory data, fostering stronger collaboration.

Benefits of Buffer Stock

Buffer stock ensures uninterrupted production by maintaining a reserve of critical materials, reducing the risk of stockouts caused by supply chain delays. It improves customer satisfaction by enabling faster response times and consistent product availability, which helps maintain sales and market reputation. Buffer stock also provides flexibility to absorb demand fluctuations, minimizing the impact of sudden spikes or drops in orders without halting operations.

Common Challenges in Managing Consignment and Buffer Stock

Managing consignment stock and buffer stock presents challenges such as visibility issues, as consignment stock remains on supplier premises, complicating accurate inventory tracking and demand forecasting. Buffer stock requires precise calculation to prevent excess holding costs or stockouts, which can disrupt production schedules. Both inventory types demand robust collaboration between suppliers and buyers to synchronize supply chain operations and maintain optimal stock levels.

Industry Applications: When to Use Each Stock Strategy

Consignment stock is ideal for industries with fluctuating demand and the need to minimize working capital, such as automotive and electronics manufacturing, where suppliers retain ownership until goods are used. Buffer stock suits sectors with unpredictable supply chain disruptions or variable lead times, like pharmaceuticals and food processing, ensuring production continuity and customer service levels. Selecting between consignment and buffer stock depends on factors like inventory carrying cost, supplier reliability, and production scheduling requirements in specific industrial applications.

Cost Implications and Financial Considerations

Consignment stock reduces upfront capital expenditure by allowing companies to hold inventory without immediate payment, improving cash flow but potentially increasing carrying costs due to extended storage periods. Buffer stock requires direct investment, tying up working capital and incurring holding costs such as warehousing, insurance, and depreciation, which can impact liquidity. Choosing between consignment and buffer stock hinges on balancing cost of capital, inventory turnover rates, and financial risk tolerance to optimize overall supply chain expenses.

Choosing the Right Inventory Management Approach

Choosing the right inventory management approach between consignment stock and buffer stock depends on factors such as cash flow, supplier relationships, and demand variability. Consignment stock reduces upfront investment by keeping supplier-owned inventory at the buyer's location, improving liquidity and minimizing holding costs. Buffer stock, maintained by the buyer, provides a safety net against supply chain disruptions and demand spikes, crucial for businesses with unpredictable sales patterns or longer lead times.

Consignment Stock Infographic

libterm.com

libterm.com