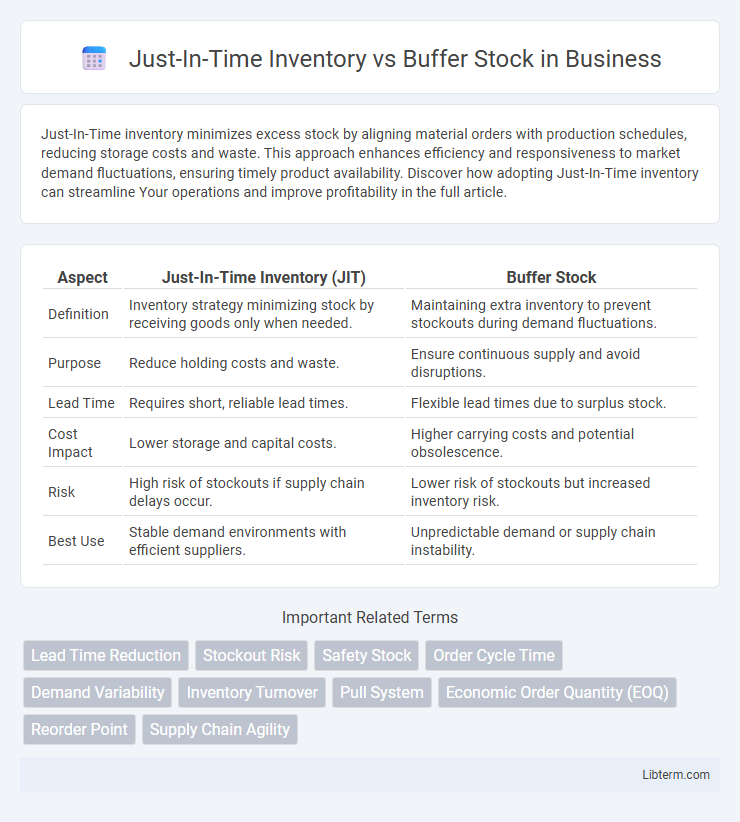

Just-In-Time inventory minimizes excess stock by aligning material orders with production schedules, reducing storage costs and waste. This approach enhances efficiency and responsiveness to market demand fluctuations, ensuring timely product availability. Discover how adopting Just-In-Time inventory can streamline Your operations and improve profitability in the full article.

Table of Comparison

| Aspect | Just-In-Time Inventory (JIT) | Buffer Stock |

|---|---|---|

| Definition | Inventory strategy minimizing stock by receiving goods only when needed. | Maintaining extra inventory to prevent stockouts during demand fluctuations. |

| Purpose | Reduce holding costs and waste. | Ensure continuous supply and avoid disruptions. |

| Lead Time | Requires short, reliable lead times. | Flexible lead times due to surplus stock. |

| Cost Impact | Lower storage and capital costs. | Higher carrying costs and potential obsolescence. |

| Risk | High risk of stockouts if supply chain delays occur. | Lower risk of stockouts but increased inventory risk. |

| Best Use | Stable demand environments with efficient suppliers. | Unpredictable demand or supply chain instability. |

Introduction to Inventory Management Strategies

Just-In-Time Inventory minimizes holding costs by receiving goods only as needed for production, improving cash flow and reducing waste. Buffer Stock maintains a safety quantity to absorb demand fluctuations and supply delays, ensuring continuous operations and customer satisfaction. Choosing between these strategies depends on factors like supplier reliability, production variability, and cost management priorities.

Defining Just-In-Time (JIT) Inventory

Just-In-Time (JIT) Inventory is a strategy aiming to minimize inventory holding by receiving goods only as they are needed in the production process, reducing storage costs and waste. This approach relies heavily on accurate demand forecasting and efficient supplier coordination to ensure materials arrive exactly when required. JIT contrasts with buffer stock, which maintains extra inventory as a safety net against supply chain disruptions.

Understanding Buffer Stock: A Safety Net Approach

Buffer stock acts as a safety net by maintaining extra inventory to absorb uncertainties in demand and supply disruptions, ensuring continuous production and customer service. Unlike Just-In-Time Inventory, which minimizes stock levels to reduce holding costs, buffer stock prioritizes risk reduction by providing a cushion against variability. This strategy is essential for industries facing unpredictable supply chains or demand spikes, balancing operational efficiency with reliability.

Key Differences Between JIT and Buffer Stock

Just-In-Time (JIT) inventory minimizes stock levels by receiving goods only as needed for production, reducing holding costs and waste. Buffer stock, or safety stock, maintains extra inventory to prevent stockouts caused by demand fluctuations or supply chain disruptions. JIT emphasizes lean operations and efficiency, while buffer stock prioritizes risk management and continuity in supply chain operations.

Benefits of Just-In-Time Inventory Systems

Just-In-Time (JIT) inventory systems minimize holding costs by reducing excess stock, leading to improved cash flow and reduced waste. JIT enhances operational efficiency through precise demand forecasting and streamlined production processes, resulting in faster response times to market changes. Companies adopting JIT benefit from increased product quality and lower storage requirements, driving overall competitive advantage.

Advantages of Maintaining Buffer Stock

Maintaining buffer stock ensures continuous production by protecting against supply chain disruptions and demand fluctuations, reducing the risk of stockouts. It enhances customer satisfaction through immediate order fulfillment, especially during peak seasons or unexpected surges in demand. Buffer stock also provides a safety margin, allowing companies to manage lead time variability and supplier delays effectively.

Risks and Challenges of JIT Inventory

Just-In-Time (JIT) inventory systems face risks such as supply chain disruptions, which can halt production due to the minimal stock buffer. JIT requires precise demand forecasting and timely deliveries, making it vulnerable to delays, supplier issues, and unexpected demand spikes. This lack of inventory cushion increases the challenge of maintaining continuous operations compared to buffer stock strategies.

Potential Drawbacks of Buffer Stocking

Buffer stocking can lead to increased holding costs due to the need for additional storage space and insurance expenses. Excess inventory may become obsolete or deteriorate over time, resulting in significant financial losses. This approach also ties up capital that could otherwise be used for other operational investments or innovations.

Choosing the Right Inventory Method for Your Business

Selecting the right inventory method hinges on your business's demand patterns, supply chain reliability, and cost structure. Just-In-Time (JIT) inventory minimizes holding costs by synchronizing stock arrivals with production schedules, ideal for businesses with stable supplier relationships and predictable demand. Buffer stock ensures a safety net against demand fluctuations and supply delays, making it suitable for industries where stockouts could lead to significant lost sales or customer dissatisfaction.

Future Trends in Inventory Management

Future trends in inventory management emphasize the integration of Just-In-Time (JIT) inventory systems with advanced data analytics and AI-driven demand forecasting to minimize holding costs while maintaining supply chain agility. Buffer stock strategies are evolving through real-time monitoring technologies and IoT applications, enabling dynamic safety stock adjustments that respond instantly to market fluctuations and disruptions. The convergence of these approaches aims to optimize inventory levels, reduce waste, and enhance responsiveness in increasingly complex global supply chains.

Just-In-Time Inventory Infographic

libterm.com

libterm.com