Pipeline inventory refers to the stock of goods that are currently in transit between different stages of the supply chain, from the supplier to the customer. Managing this inventory effectively ensures timely delivery and minimizes holding costs, optimizing overall supply chain efficiency. Explore the rest of the article to learn how your business can master pipeline inventory management for smoother operations.

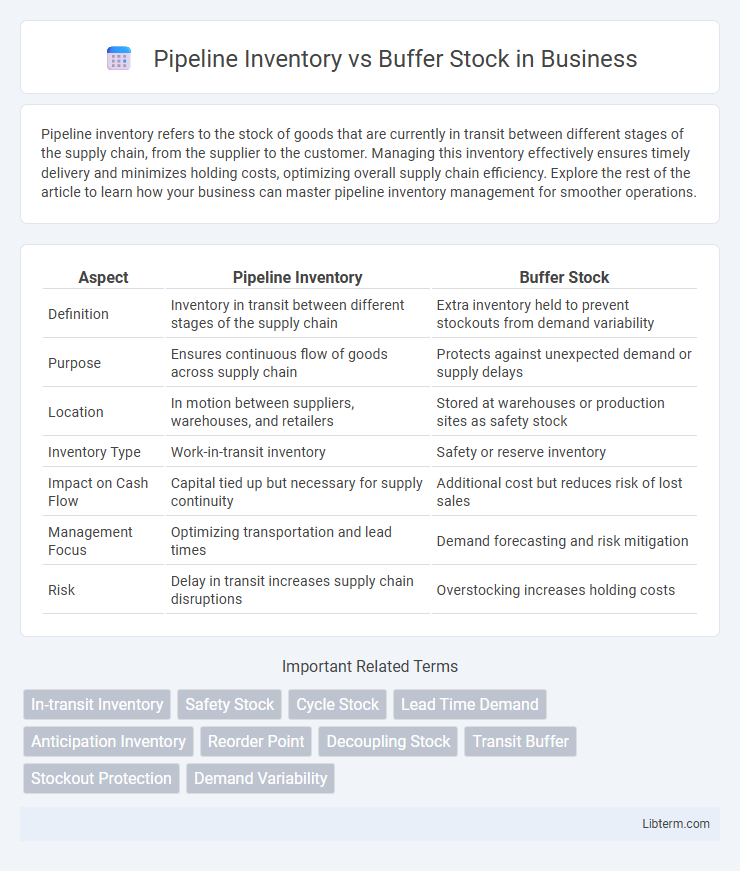

Table of Comparison

| Aspect | Pipeline Inventory | Buffer Stock |

|---|---|---|

| Definition | Inventory in transit between different stages of the supply chain | Extra inventory held to prevent stockouts from demand variability |

| Purpose | Ensures continuous flow of goods across supply chain | Protects against unexpected demand or supply delays |

| Location | In motion between suppliers, warehouses, and retailers | Stored at warehouses or production sites as safety stock |

| Inventory Type | Work-in-transit inventory | Safety or reserve inventory |

| Impact on Cash Flow | Capital tied up but necessary for supply continuity | Additional cost but reduces risk of lost sales |

| Management Focus | Optimizing transportation and lead times | Demand forecasting and risk mitigation |

| Risk | Delay in transit increases supply chain disruptions | Overstocking increases holding costs |

Introduction to Pipeline Inventory and Buffer Stock

Pipeline inventory refers to goods that are currently in transit between different stages of the supply chain, including raw materials, work-in-progress, and finished products moving from suppliers to warehouses or customers. Buffer stock is a reserved quantity of inventory maintained to protect against uncertainties such as demand fluctuations, supply delays, or production disruptions. Both concepts are critical for effective inventory management, ensuring smooth operations and minimizing the risk of stockouts or excess inventory.

Defining Pipeline Inventory: Meaning and Examples

Pipeline inventory refers to the stock of goods that are currently in transit between different stages of the supply chain, such as from suppliers to warehouses or from warehouses to retail outlets. This inventory is essential for maintaining continuous production and meeting customer demand without delays, examples include raw materials being shipped to a factory or finished products en route to distribution centers. Unlike buffer stock, which acts as a safety reserve to absorb demand fluctuations, pipeline inventory represents active goods moving through the supply chain process.

What is Buffer Stock? Key Characteristics

Buffer stock refers to extra inventory held to mitigate supply chain uncertainties and demand fluctuations. Key characteristics include maintaining safety levels to prevent stockouts, absorbing lead time variability, and providing flexibility in production and delivery schedules. It acts as a cushion against unexpected disruptions, ensuring continuous operations and customer satisfaction.

Main Differences Between Pipeline Inventory and Buffer Stock

Pipeline inventory refers to goods that are in transit between different stages of the supply chain, representing products that have been ordered but not yet received. Buffer stock, also known as safety stock, is inventory held to mitigate uncertainties in demand and supply, preventing stockouts caused by delays or sudden demand spikes. The main difference lies in their purpose: pipeline inventory accounts for lead time in movement, while buffer stock provides a cushion against variability in demand or supply disruptions.

Roles of Pipeline Inventory in Supply Chain Efficiency

Pipeline inventory plays a critical role in supply chain efficiency by ensuring continuous product flow between production and consumption points, minimizing stockouts and production delays. It serves as the transit stock that absorbs lead time variability, supporting smooth operations and timely order fulfillment. Unlike buffer stock, which acts as a safety reserve against demand fluctuations, pipeline inventory directly links supply chain stages, optimizing overall system responsiveness and resource utilization.

Importance of Buffer Stock in Inventory Management

Buffer stock plays a crucial role in inventory management by providing a safety net against demand fluctuations and supply chain disruptions, ensuring continuous production and customer service. Unlike pipeline inventory, which represents goods in transit or processing, buffer stock is strategically held to absorb uncertainties in lead time and demand variability. Maintaining adequate buffer stock minimizes stockouts, reduces lost sales, and supports consistent inventory levels for efficient operations.

Advantages and Disadvantages of Pipeline Inventory

Pipeline inventory maintains a continuous flow of goods between production and consumption, reducing the risk of stockouts and ensuring smoother operations. However, it ties up capital as inventory remains in transit, increasing holding costs and limiting flexibility to respond to sudden demand changes. This type of inventory also requires accurate demand forecasting to avoid excess stock and potential obsolescence.

Benefits and Challenges of Maintaining Buffer Stock

Maintaining buffer stock ensures product availability during supply chain disruptions, minimizing stockouts and enhancing customer satisfaction, but it requires significant capital investment and storage space. Buffer stock acts as a safety net to absorb demand variability and lead time fluctuations, supporting continuous production and order fulfillment. However, excessive buffer stock can lead to increased holding costs and potential obsolescence, necessitating careful inventory management strategies.

Strategic Approaches: When to Use Pipeline vs Buffer Stock

Pipeline inventory is strategically used when lead times are long and demand is predictable, ensuring a continuous flow of materials through the supply chain without interruption. Buffer stock serves as a tactical reserve to absorb demand variability and supply delays, particularly useful in environments with high uncertainty or fluctuating demand patterns. Businesses often combine both approaches by maintaining pipeline inventory for steady replenishment while holding buffer stock as a safeguard against sudden disruptions and demand spikes.

Conclusion: Optimizing Inventory for Business Success

Optimizing inventory requires balancing pipeline inventory, which includes goods in transit or production stages, with buffer stock that safeguards against demand fluctuations. Efficient management of both types minimizes holding costs while ensuring smooth operations, preventing stockouts and delays. Strategic inventory control enhances cash flow, responsiveness, and overall business success by aligning supply chain activities with market demands.

Pipeline Inventory Infographic

libterm.com

libterm.com