Vertical integration enhances your control over the supply chain by merging production stages under one company, resulting in reduced costs and improved efficiency. This business strategy can strengthen competitive advantage by ensuring consistent quality and faster time-to-market. Explore the rest of this article to learn how vertical integration can transform your company's operations and profitability.

Table of Comparison

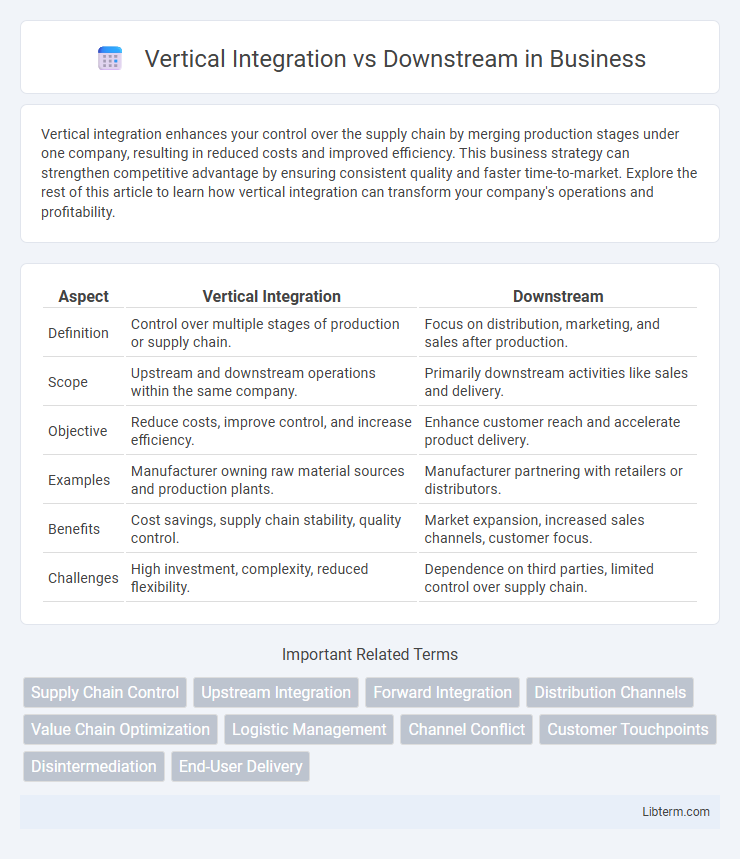

| Aspect | Vertical Integration | Downstream |

|---|---|---|

| Definition | Control over multiple stages of production or supply chain. | Focus on distribution, marketing, and sales after production. |

| Scope | Upstream and downstream operations within the same company. | Primarily downstream activities like sales and delivery. |

| Objective | Reduce costs, improve control, and increase efficiency. | Enhance customer reach and accelerate product delivery. |

| Examples | Manufacturer owning raw material sources and production plants. | Manufacturer partnering with retailers or distributors. |

| Benefits | Cost savings, supply chain stability, quality control. | Market expansion, increased sales channels, customer focus. |

| Challenges | High investment, complexity, reduced flexibility. | Dependence on third parties, limited control over supply chain. |

Introduction to Vertical Integration and Downstream Operations

Vertical integration involves a company expanding its operations into different stages of production or distribution within the same industry, enhancing control over the supply chain. Downstream operations refer to activities related to the distribution, marketing, and sale of finished products to consumers, including retail and customer service. Combining vertical integration with effective downstream management optimizes efficiency, reduces costs, and improves market responsiveness.

Defining Vertical Integration

Vertical integration refers to a company's ownership and control over multiple stages of its supply chain, from production to distribution. This strategy enhances operational efficiency by reducing costs, improving coordination, and securing supply sources. In contrast, downstream activities specifically involve processes related to the distribution, marketing, and sale of finished products to consumers.

Understanding Downstream Activities

Downstream activities in the oil and gas industry involve refining, marketing, and distributing petroleum products to end consumers, highlighting the transformation of raw materials into usable goods. Vertical integration encompasses control over multiple stages of production, including upstream exploration, midstream transportation, and downstream refining and retail, enhancing operational efficiency and market control. Understanding downstream processes is crucial for optimizing supply chains, meeting regulatory requirements, and responding to consumer demand within the energy sector.

Key Differences Between Vertical Integration and Downstream Strategies

Vertical integration involves a company controlling multiple stages of the supply chain, from production to distribution, enhancing operational efficiency and cost control. Downstream strategies focus specifically on activities related to product distribution, marketing, and customer service, aiming to increase market presence and customer engagement. The key difference lies in vertical integration encompassing both upstream and downstream processes, while downstream strategies concentrate solely on the post-production segment of the value chain.

Advantages of Vertical Integration

Vertical integration enhances supply chain control, reducing dependency on external suppliers and minimizing disruptions. It allows companies to achieve cost savings through economies of scale and improved operational efficiencies. Greater quality control and faster time-to-market contribute to stronger competitive advantages and increased profitability.

Benefits and Challenges of Downstream Expansion

Downstream expansion enhances control over product distribution and customer experience, increasing profit margins by capturing value closer to end consumers. It poses challenges such as high capital investment in retail infrastructure, complex logistics management, and increased exposure to market fluctuations and consumer preferences. Effective downstream integration demands strong marketing strategies and adaptability to changing consumer demands to maximize benefits.

Industry Examples: Vertical Integration vs Downstream Focus

Tesla exemplifies vertical integration by controlling battery production, vehicle assembly, and retail sales, reducing reliance on external suppliers and enhancing innovation speed. In contrast, oil giants like ExxonMobil emphasize downstream operations, focusing on refining crude oil into finished products and distribution to consumers. These strategies highlight how vertical integration drives internal control and cost savings, while downstream focus optimizes market access and customer service.

Strategic Considerations for Choosing Integration Pathways

Vertical integration involves controlling multiple stages of the supply chain to enhance efficiency and reduce costs, while downstream integration emphasizes control over distribution, marketing, and sales to improve customer reach and market responsiveness. Strategic considerations for choosing between these pathways include analyzing industry-specific demand elasticity, control over proprietary technology, and the competitiveness of distribution channels. Firms prioritize vertical integration when aiming for cost leadership and quality control, whereas downstream integration suits businesses focused on brand differentiation and customer engagement.

Risk Factors in Vertical and Downstream Integration

Vertical integration involves controlling multiple stages of production or supply chain, which increases exposure to operational risks such as higher capital investment, reduced flexibility, and supplier dependency. Downstream integration, focusing on distribution and sales, carries risks related to market demand fluctuations, increased customer service obligations, and potential overextension into unfamiliar retail or marketing territories. Both strategies require careful risk management to balance control benefits with vulnerabilities inherent in expanded operational scope.

Future Trends in Vertical and Downstream Operations

Future trends in vertical integration emphasize leveraging advanced digital technologies like AI and IoT to enhance supply chain visibility and operational efficiency. Downstream operations are increasingly adopting sustainable practices and data-driven customer engagement to optimize distribution and retail strategies. Both vertical and downstream sectors are shifting towards more agile, tech-enabled models to meet evolving market demands and regulatory landscapes.

Vertical Integration Infographic

libterm.com

libterm.com