Lean methodology focuses on maximizing value by minimizing waste and improving processes efficiently. It emphasizes continuous improvement, empowering teams to deliver faster results while maintaining high quality. Explore the full article to discover how Lean principles can transform your business operations.

Table of Comparison

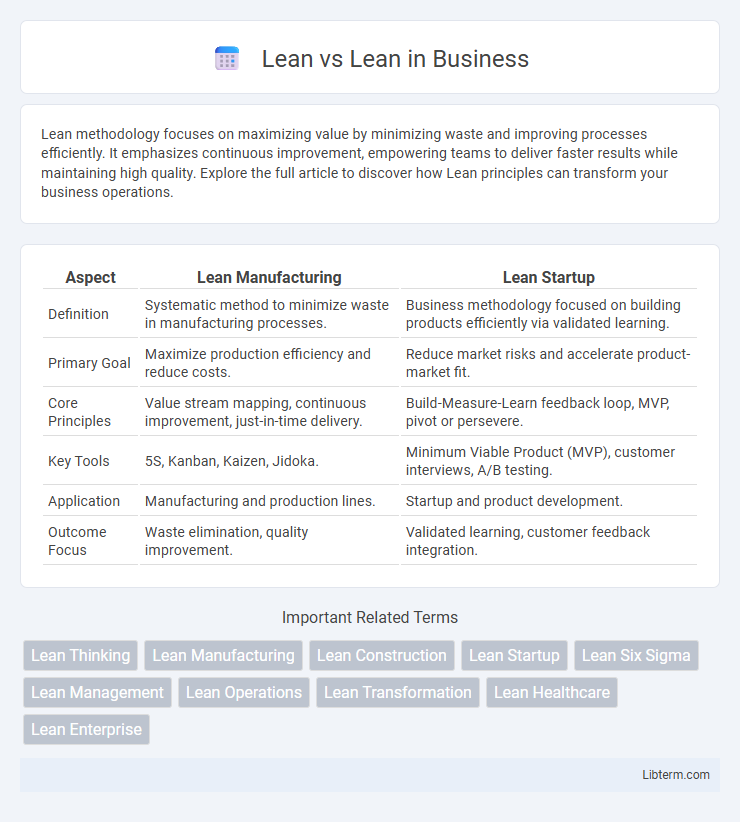

| Aspect | Lean Manufacturing | Lean Startup |

|---|---|---|

| Definition | Systematic method to minimize waste in manufacturing processes. | Business methodology focused on building products efficiently via validated learning. |

| Primary Goal | Maximize production efficiency and reduce costs. | Reduce market risks and accelerate product-market fit. |

| Core Principles | Value stream mapping, continuous improvement, just-in-time delivery. | Build-Measure-Learn feedback loop, MVP, pivot or persevere. |

| Key Tools | 5S, Kanban, Kaizen, Jidoka. | Minimum Viable Product (MVP), customer interviews, A/B testing. |

| Application | Manufacturing and production lines. | Startup and product development. |

| Outcome Focus | Waste elimination, quality improvement. | Validated learning, customer feedback integration. |

Introduction: Defining "Lean vs Lean

Lean vs Lean" explores two distinct applications of lean principles: Lean manufacturing and Lean startup. Lean manufacturing focuses on waste reduction and efficiency in production processes, while Lean startup emphasizes rapid experimentation and validated learning to minimize market risks. Understanding their unique goals and methodologies clarifies how each approach drives innovation and operational excellence.

Origins and Evolution of Lean Principles

Lean originated from the Toyota Production System (TPS) developed in post-World War II Japan, emphasizing waste reduction and continuous improvement. Over time, Lean principles evolved beyond manufacturing, adapting to various industries by focusing on value stream mapping, just-in-time production, and respect for people. The evolution of Lean incorporates modern methodologies like Agile and Six Sigma, enhancing flexibility and quality in processes worldwide.

Lean Manufacturing: Core Concepts

Lean Manufacturing centers on eliminating waste through continuous improvement and value stream mapping. Key principles include just-in-time production, reducing inventory, and empowering workers to identify inefficiencies. Tools such as Kaizen, 5S, and kanban drive streamlined processes and enhance productivity across manufacturing operations.

Lean Management: Broader Applications

Lean Management extends beyond manufacturing to streamline processes across diverse industries such as healthcare, software development, and service sectors. Emphasizing value creation, waste reduction, and continuous improvement, Lean principles enhance operational efficiency and customer satisfaction. Key tools like value stream mapping, Kaizen, and 5S foster a culture of agility and responsiveness in complex organizational environments.

Key Similarities between Lean Approaches

Lean projects prioritize waste reduction and continuous improvement, aiming to enhance value delivery efficiently. Both Lean Manufacturing and Lean Startup emphasize iterative feedback loops and employee or customer involvement for process optimization. The core principles of minimizing resource use and maximizing customer value unite these methodologies across different industries.

Distinct Differences: Manufacturing vs. Management

Lean Manufacturing concentrates on eliminating waste and optimizing production processes to enhance efficiency and reduce costs on the factory floor. Lean Management, however, applies these principles broadly across an organization, emphasizing continuous improvement, employee engagement, and strategic decision-making. The distinct difference lies in Lean Manufacturing's focus on tangible operational improvements, while Lean Management targets overall organizational culture and leadership practices.

Benefits of Embracing Lean in Organizations

Embracing Lean in organizations drives significant efficiency by minimizing waste and streamlining processes, leading to reduced operational costs and faster delivery times. It fosters a culture of continuous improvement, empowering employees to identify bottlenecks and implement effective solutions. The resulting enhanced product quality and customer satisfaction directly contribute to sustainable competitive advantage and long-term business growth.

Potential Challenges and Misconceptions

Lean methodology, focused on maximizing value and minimizing waste, often faces challenges such as employee resistance and misaligned organizational culture that can hinder its implementation. Common misconceptions include equating Lean solely with cost-cutting rather than continuous improvement and misunderstanding that Lean applies only to manufacturing, neglecting its benefits across various industries and processes. Successfully overcoming these obstacles requires clear communication, comprehensive training, and leadership commitment to embed Lean principles into the company's core practices.

Real-World Case Studies: Lean in Action

Real-world case studies demonstrate Lean's transformative impact across diverse industries by streamlining processes and eliminating waste. Companies like Toyota and Intel showcase how Lean methodologies enhance operational efficiency, reduce costs, and boost customer satisfaction through continuous improvement practices. These practical examples highlight Lean's adaptability in optimizing workflows and fostering a culture of sustained innovation.

Conclusion: Choosing the Right Lean Approach

Selecting the appropriate Lean methodology depends on organizational goals, industry requirements, and cultural fit, with Lean Six Sigma excelling in process optimization through data-driven analysis and Lean Manufacturing emphasizing waste reduction and flow efficiency. Companies aiming for continuous quality improvement may prioritize Lean Six Sigma for its structured DMAIC framework, while those focused on streamlining production and minimizing non-value activities benefit from Lean principles. Tailoring the Lean approach to specific operational challenges maximizes efficiency gains and sustains long-term competitive advantages.

Lean Infographic

libterm.com

libterm.com