Six Sigma is a data-driven methodology aimed at improving business processes by reducing defects and variability, thus enhancing overall quality and efficiency. It utilizes statistical tools and techniques such as DMAIC (Define, Measure, Analyze, Improve, Control) to identify root causes of problems and implement sustainable solutions. Explore the article to understand how Six Sigma can drive your organization's success and operational excellence.

Table of Comparison

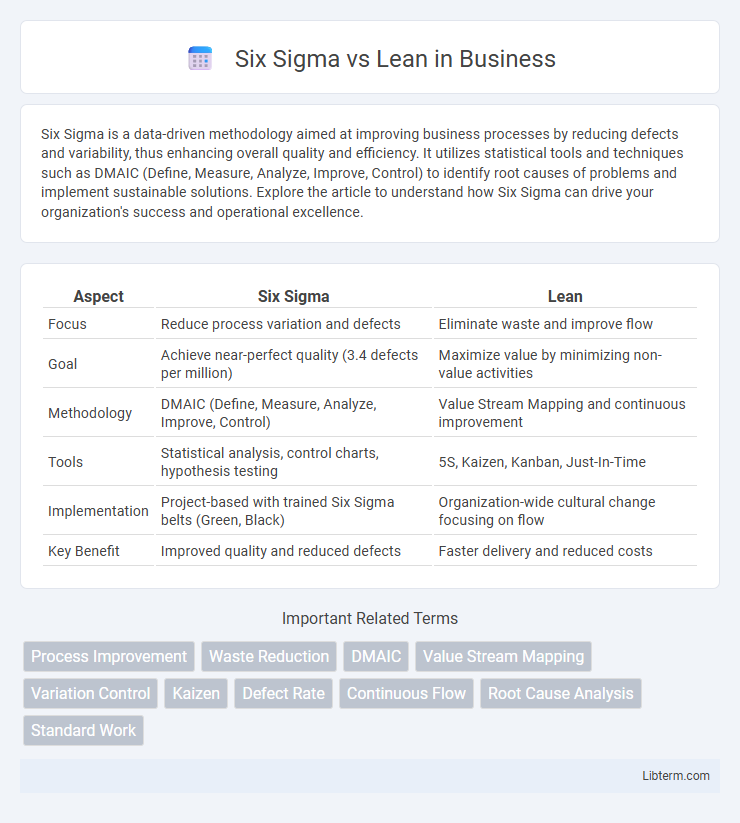

| Aspect | Six Sigma | Lean |

|---|---|---|

| Focus | Reduce process variation and defects | Eliminate waste and improve flow |

| Goal | Achieve near-perfect quality (3.4 defects per million) | Maximize value by minimizing non-value activities |

| Methodology | DMAIC (Define, Measure, Analyze, Improve, Control) | Value Stream Mapping and continuous improvement |

| Tools | Statistical analysis, control charts, hypothesis testing | 5S, Kaizen, Kanban, Just-In-Time |

| Implementation | Project-based with trained Six Sigma belts (Green, Black) | Organization-wide cultural change focusing on flow |

| Key Benefit | Improved quality and reduced defects | Faster delivery and reduced costs |

Overview of Six Sigma and Lean

Six Sigma is a data-driven methodology aimed at reducing defects and improving process quality by using statistical analysis and DMAIC (Define, Measure, Analyze, Improve, Control) framework. Lean focuses on eliminating waste and increasing process efficiency through continuous flow, value stream mapping, and just-in-time production techniques. Both methodologies drive operational excellence but utilize different tools and metrics for performance improvement.

Origins and Historical Development

Six Sigma originated in the 1980s at Motorola as a data-driven methodology aimed at reducing defects to improve quality, heavily based on statistical analysis and process control. Lean traces its roots to the Toyota Production System developed post-World War II, emphasizing waste reduction and continuous flow for manufacturing efficiency. Both Six Sigma and Lean evolved through industrial application and academic refinement, merging in Lean Six Sigma to combine waste elimination with defect reduction strategies.

Core Principles of Six Sigma

Six Sigma centers on reducing process variation and improving quality through data-driven decision-making and statistical analysis, emphasizing the DMAIC (Define, Measure, Analyze, Improve, Control) framework. Its core principles include a customer-focused approach, rigorous process measurement, and systematic problem-solving to achieve near-perfect performance with fewer than 3.4 defects per million opportunities. Lean, on the other hand, primarily targets waste elimination and process flow enhancement but integrates well with Six Sigma for comprehensive operational excellence.

Core Principles of Lean

Lean principles emphasize maximizing value by eliminating waste through techniques like continuous flow, pull systems, and value stream mapping. Six Sigma focuses on reducing variation and improving quality using data-driven methodologies such as DMAIC (Define, Measure, Analyze, Improve, Control). Lean's core principles of value, value stream, flow, pull, and perfection drive efficiency by streamlining processes and enhancing customer satisfaction.

Key Tools and Techniques in Six Sigma

Six Sigma utilizes key tools and techniques such as DMAIC (Define, Measure, Analyze, Improve, Control) methodology, statistical process control (SPC), and root cause analysis to reduce variation and improve quality. Tools like Failure Modes and Effects Analysis (FMEA), Pareto charts, and hypothesis testing enable data-driven decision making and process improvement. These techniques focus on identifying defects, minimizing errors, and ensuring consistent outputs throughout production and service processes.

Key Tools and Techniques in Lean

Lean methodology employs key tools and techniques such as Value Stream Mapping to visualize workflow and identify waste, 5S for workplace organization, and Kaizen for continuous incremental improvements. Other essential Lean tools include Kanban for workflow management, Just-In-Time (JIT) production to reduce inventory and increase efficiency, and Root Cause Analysis to address process deficiencies. These tools collectively drive waste reduction, enhance process flow, and improve overall operational efficiency in Lean environments.

Differences in Methodology and Approach

Six Sigma employs a data-driven methodology focused on reducing process variation and defects through statistical analysis, using the DMAIC (Define, Measure, Analyze, Improve, Control) framework. Lean emphasizes waste elimination and flow improvement by identifying and removing non-value-added activities to enhance process efficiency and speed. While Six Sigma targets quality improvement through precision and control, Lean prioritizes process simplification and continuous flow to maximize value delivery.

Benefits and Drawbacks of Six Sigma vs Lean

Six Sigma delivers data-driven decision-making and defect reduction, enhancing product quality and customer satisfaction but can be complex to implement and require extensive training. Lean improves process efficiency by eliminating waste and reducing lead times, resulting in cost savings and faster delivery, though it may overlook variations in quality control. Combining both methodologies can optimize operational performance by balancing efficiency with quality assurance.

Choosing the Right Approach for Your Organization

Choosing the right approach between Six Sigma and Lean depends on your organization's specific goals and challenges; Six Sigma targets reducing process variation and defects through data-driven methodologies, while Lean emphasizes eliminating waste and streamlining workflows for efficiency. Organizations seeking quality improvement with a focus on statistical control may benefit more from Six Sigma, whereas those aiming to enhance operational speed and reduce costs often find Lean more effective. An integrated Lean Six Sigma approach can deliver comprehensive performance improvements by combining the strengths of both methodologies tailored to organizational needs.

Integrating Six Sigma and Lean for Maximum Impact

Integrating Six Sigma and Lean methodologies drives maximum impact by combining Six Sigma's data-driven approach to reducing defects with Lean's focus on eliminating waste in processes. Organizations experience improved quality, faster delivery times, and enhanced operational efficiency by leveraging Six Sigma's statistical tools alongside Lean's value stream mapping and continuous flow principles. This synergy facilitates a culture of continuous improvement that optimizes both process consistency and speed.

Six Sigma Infographic

libterm.com

libterm.com