OEM (Original Equipment Manufacturer) refers to companies that produce parts or components used in another company's end products, ensuring high-quality standards and compatibility. Understanding OEM's role can help Your business optimize production costs and maintain product reliability. Explore the rest of the article to learn how OEM partnerships can benefit Your operations.

Table of Comparison

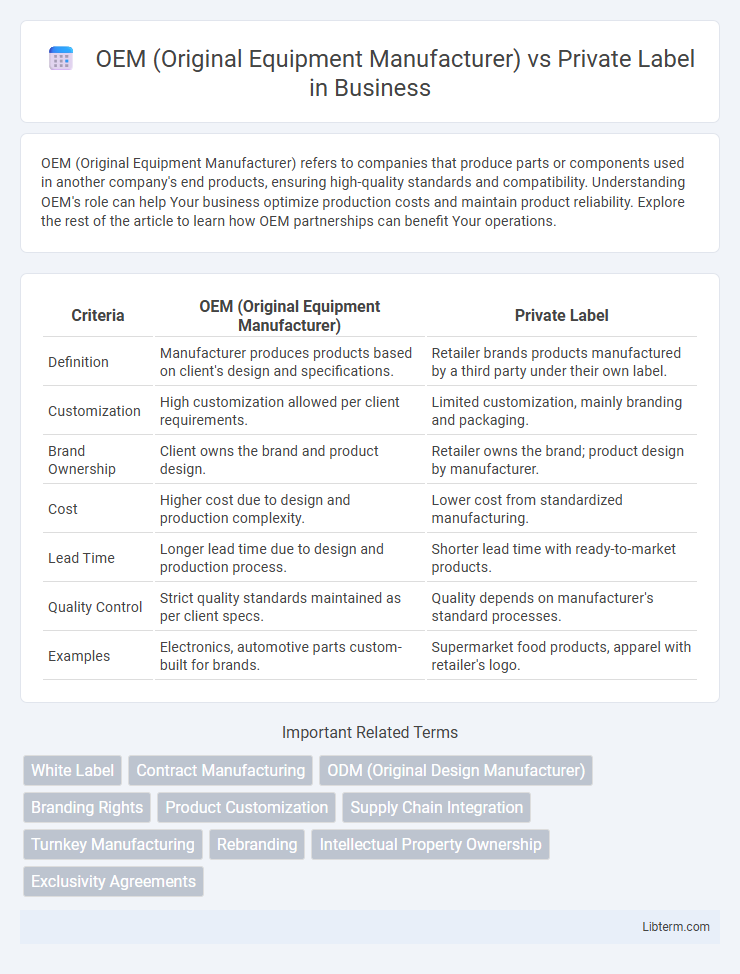

| Criteria | OEM (Original Equipment Manufacturer) | Private Label |

|---|---|---|

| Definition | Manufacturer produces products based on client's design and specifications. | Retailer brands products manufactured by a third party under their own label. |

| Customization | High customization allowed per client requirements. | Limited customization, mainly branding and packaging. |

| Brand Ownership | Client owns the brand and product design. | Retailer owns the brand; product design by manufacturer. |

| Cost | Higher cost due to design and production complexity. | Lower cost from standardized manufacturing. |

| Lead Time | Longer lead time due to design and production process. | Shorter lead time with ready-to-market products. |

| Quality Control | Strict quality standards maintained as per client specs. | Quality depends on manufacturer's standard processes. |

| Examples | Electronics, automotive parts custom-built for brands. | Supermarket food products, apparel with retailer's logo. |

Definition of OEM and Private Label

OEM (Original Equipment Manufacturer) refers to a company that designs and produces products or components that are marketed by another company under its own brand name. Private Label involves a retailer or company sourcing products from a manufacturer and selling them under its own brand, typically with limited customization or design input. Both models enable brand owners to offer products without directly engaging in manufacturing, but OEMs often have greater control over product design and specifications.

Key Differences Between OEM and Private Label

OEM (Original Equipment Manufacturer) produces products based on the buyer's specifications, allowing full customization of design and components. Private label products are manufactured by a third party and sold under a retailer's brand, often using standardized designs with minimal customization. The key difference lies in control over product development: OEM offers extensive input and unique designs, while private label relies on existing products rebranded for different markets.

How OEM Works: Processes and Partnerships

OEM (Original Equipment Manufacturer) involves a collaborative process where a company designs and manufactures products that are branded and sold by another company. The process begins with the hiring brand providing detailed specifications and design requirements to the OEM, which then handles production, quality control, and compliance testing. Successful OEM partnerships rely on clear communication, mutual trust, and long-term contracts to ensure consistent product quality and timely delivery.

Understanding Private Label: Business Models

Private Label business models involve retailers or companies branding products manufactured by third parties under their own name, allowing customization of packaging and design while leveraging existing manufacturing expertise. This approach reduces development costs and shortens time-to-market compared to OEM models, where products are produced strictly to the specifications of a brand owner. Private Label enables greater control over brand identity and pricing strategies, often enhancing profit margins through exclusivity agreements with manufacturers.

Pros and Cons of OEM

OEM (Original Equipment Manufacturer) offers the advantage of customizing products to specific brand requirements, ensuring higher quality control and unique branding opportunities. However, OEM typically involves higher upfront costs and longer lead times compared to Private Label options, which may limit flexibility for smaller businesses. Dependence on OEM manufacturers can also pose risks if there are supply chain disruptions or changes in production standards.

Pros and Cons of Private Label

Private Label products offer businesses greater control over branding and product specifications, often resulting in higher profit margins and stronger customer loyalty due to unique offerings. However, the challenges include substantial upfront investment in product development, potential quality control issues, and the responsibility for marketing and distribution. Unlike OEM, Private Label requires managing inventory risks and building brand recognition from scratch.

Cost Considerations: OEM vs. Private Label

OEM products typically involve higher upfront costs due to custom engineering and strict quality standards, but benefit from economies of scale in large production runs. Private label manufacturing offers lower initial investment by utilizing existing product designs, allowing brands to enter markets quickly with reduced development expenses. Evaluating cost considerations between OEM and private label hinges on balancing product customization needs against budget constraints and long-term production volume.

Branding Implications for OEM and Private Label

OEM products carry the brand identity of the purchasing company, allowing for consistent brand messaging and customer loyalty enhancement while leveraging the manufacturer's expertise. Private label products offer retailers the opportunity to build their own brand presence by customizing product design and packaging, which strengthens direct consumer recognition and market differentiation. Both models impact brand equity differently: OEM emphasizes quality association with an established brand, whereas private label fosters exclusivity and tailored brand experiences.

Choosing Between OEM and Private Label: Factors to Consider

Choosing between OEM and private label depends on factors like control over product design, branding, and manufacturing costs. OEM offers customization and direct involvement in product specifications, while private label allows quicker market entry with established products under your brand. Assess market demands, budget constraints, and long-term brand strategy to determine the ideal approach for your business.

Future Trends in OEM and Private Label Manufacturing

Future trends in OEM and private label manufacturing emphasize increased customization through advanced technologies like AI and IoT to meet rapidly evolving consumer demands. Sustainability is driving OEMs and private label producers to adopt eco-friendly materials and transparent supply chains, enhancing brand trust and compliance. The integration of digital platforms for real-time collaboration and faster product development cycles is reshaping the competitive landscape, enabling more agile responses to market trends.

OEM (Original Equipment Manufacturer) Infographic

libterm.com

libterm.com