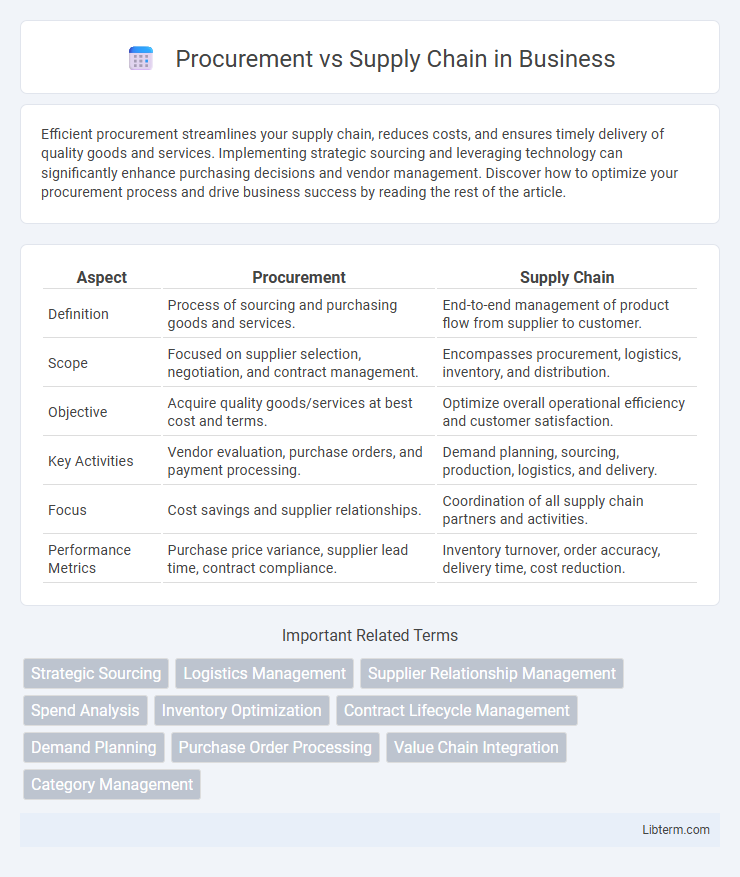

Efficient procurement streamlines your supply chain, reduces costs, and ensures timely delivery of quality goods and services. Implementing strategic sourcing and leveraging technology can significantly enhance purchasing decisions and vendor management. Discover how to optimize your procurement process and drive business success by reading the rest of the article.

Table of Comparison

| Aspect | Procurement | Supply Chain |

|---|---|---|

| Definition | Process of sourcing and purchasing goods and services. | End-to-end management of product flow from supplier to customer. |

| Scope | Focused on supplier selection, negotiation, and contract management. | Encompasses procurement, logistics, inventory, and distribution. |

| Objective | Acquire quality goods/services at best cost and terms. | Optimize overall operational efficiency and customer satisfaction. |

| Key Activities | Vendor evaluation, purchase orders, and payment processing. | Demand planning, sourcing, production, logistics, and delivery. |

| Focus | Cost savings and supplier relationships. | Coordination of all supply chain partners and activities. |

| Performance Metrics | Purchase price variance, supplier lead time, contract compliance. | Inventory turnover, order accuracy, delivery time, cost reduction. |

Understanding Procurement and Supply Chain

Procurement involves the strategic process of sourcing and purchasing goods or services critical to business operations, focusing on supplier selection, negotiation, and contract management. Supply chain encompasses the broader network of activities including procurement, logistics, production, and distribution that ensure the efficient flow of materials from suppliers to customers. Understanding the distinction highlights procurement as a key component within the supply chain, essential for optimizing cost, quality, and delivery timelines.

Key Differences Between Procurement and Supply Chain

Procurement primarily focuses on the acquisition of goods and services, encompassing activities like supplier selection, negotiation, and contract management. Supply chain management covers a broader scope that includes procurement, production, logistics, inventory management, and distribution to ensure seamless flow from raw materials to end customers. The key difference lies in procurement's concentration on sourcing and purchasing, while supply chain management integrates all processes involved in delivering products efficiently.

Core Functions of Procurement

Procurement centers on acquiring goods and services essential for business operations, involving supplier selection, contract negotiation, and purchase order management to ensure cost-effectiveness and quality compliance. It plays a crucial role in sourcing raw materials, managing supplier relationships, and securing timely delivery to meet production schedules. Unlike the broader supply chain, which encompasses logistics, inventory management, and distribution, procurement primarily focuses on strategic purchasing and supplier performance optimization.

Core Functions of Supply Chain Management

Procurement is a subset of supply chain management focused primarily on sourcing and purchasing goods and services required for production. Supply chain management encompasses broader core functions including demand planning, inventory management, logistics, and distribution to ensure seamless product flow from suppliers to customers. Efficient coordination of these functions optimizes cost, enhances delivery speed, and maintains quality across the entire supply chain.

Strategic Importance in Business Operations

Procurement plays a critical role in sourcing high-quality materials and negotiating favorable contracts, directly impacting cost efficiency and supplier relationships within business operations. Supply chain management encompasses a broader scope, integrating procurement, logistics, inventory management, and demand forecasting to optimize overall operational flow and service delivery. Strategic alignment of procurement and supply chain functions enhances competitive advantage by ensuring seamless production processes, reducing risks, and improving responsiveness to market changes.

Roles and Responsibilities in Procurement vs Supply Chain

Procurement focuses on sourcing, negotiating contracts, and purchasing goods or services at the best value, ensuring supplier compliance and cost efficiency. Supply chain management oversees the end-to-end flow of materials, information, and finances, coordinating logistics, inventory control, and demand forecasting to optimize overall operations. While procurement concentrates on supplier relationships and contract management, supply chain involves broader strategic planning and execution to deliver products to customers efficiently.

Technology Impact on Procurement and Supply Chain

Technology dramatically enhances procurement and supply chain efficiencies through automation, data analytics, and AI-driven decision-making. Advanced procurement software streamlines supplier selection and contract management, while IoT and blockchain improve supply chain transparency and traceability. Real-time data integration enables proactive risk management and optimized inventory control, driving cost reductions and faster delivery times.

Challenges Faced in Procurement and Supply Chain

Procurement challenges often include supplier reliability, cost volatility, and compliance with regulations, impacting acquisition efficiency and budget control. Supply chain issues frequently involve demand forecasting inaccuracies, logistics disruptions, and inventory management, leading to delays and increased operational costs. Both areas face risks from geopolitical tensions and technological integration failures, requiring robust risk management strategies to maintain continuity and resilience.

Integrating Procurement and Supply Chain for Efficiency

Integrating procurement and supply chain management enhances operational efficiency by aligning purchasing strategies with inventory control, demand forecasting, and supplier collaboration. Leveraging technologies such as ERP systems and real-time data analytics ensures transparency across procurement and supply networks, reducing lead times and minimizing costs. Effective integration drives synchronized workflows, improves supplier performance metrics, and optimizes resource allocation throughout the supply chain.

Future Trends in Procurement and Supply Chain Management

Future trends in procurement emphasize the integration of artificial intelligence, blockchain technology, and predictive analytics to enhance transparency, efficiency, and risk management. Supply chain management is evolving with increased automation, IoT-enabled real-time tracking, and sustainable practices to meet growing demands for agility and environmental responsibility. Both procurement and supply chain functions are leveraging advanced data analytics and digital platforms to foster collaboration, reduce costs, and improve decision-making accuracy.

Procurement Infographic

libterm.com

libterm.com