Operations strategy focuses on aligning your company's resources and processes to achieve long-term business objectives while maximizing efficiency and competitiveness. It involves decisions on production, supply chain management, quality control, and capacity planning to deliver value to customers consistently. Explore the rest of the article to understand how effective operations strategy can transform your organization's performance.

Table of Comparison

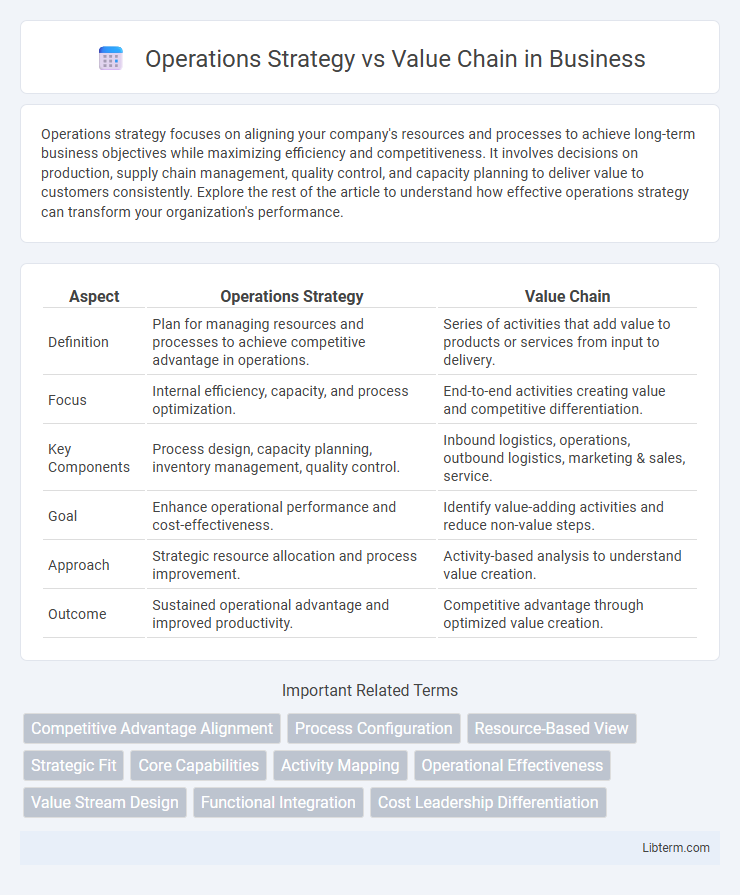

| Aspect | Operations Strategy | Value Chain |

|---|---|---|

| Definition | Plan for managing resources and processes to achieve competitive advantage in operations. | Series of activities that add value to products or services from input to delivery. |

| Focus | Internal efficiency, capacity, and process optimization. | End-to-end activities creating value and competitive differentiation. |

| Key Components | Process design, capacity planning, inventory management, quality control. | Inbound logistics, operations, outbound logistics, marketing & sales, service. |

| Goal | Enhance operational performance and cost-effectiveness. | Identify value-adding activities and reduce non-value steps. |

| Approach | Strategic resource allocation and process improvement. | Activity-based analysis to understand value creation. |

| Outcome | Sustained operational advantage and improved productivity. | Competitive advantage through optimized value creation. |

Introduction to Operations Strategy and Value Chain

Operations strategy defines long-term planning and decision-making processes to optimize production efficiency and resource allocation. The value chain identifies and analyzes each step involved in delivering a product or service, highlighting points where value is added. Together, these frameworks enable organizations to align operational activities with competitive advantage and customer satisfaction.

Defining Operations Strategy

Defining operations strategy involves aligning the organization's resources and processes with its long-term goals to gain competitive advantage. It focuses on decisions related to capacity, process technology, supply chain management, and workforce skills that directly impact operational performance. Operations strategy ensures consistent delivery of value by optimizing activities within the value chain, enhancing efficiency and customer satisfaction.

Understanding the Value Chain Concept

Understanding the value chain concept involves analyzing the series of activities businesses perform to deliver a product or service, emphasizing how each step adds value and impacts competitive advantage. Operations strategy focuses on optimizing these activities to improve efficiency, quality, and customer satisfaction within the value chain framework. Effective integration of operations strategy with value chain analysis enables organizations to identify cost-saving opportunities and enhance product differentiation.

Key Differences Between Operations Strategy and Value Chain

Operations strategy focuses on long-term planning to optimize production processes, resource allocation, and competitive advantage within a business. The value chain emphasizes the sequence of activities involved in creating value for customers, from inbound logistics to after-sales service, highlighting how each step adds value. Key differences lie in operations strategy's macro-level approach to operational decisions versus the value chain's micro-level analysis of value-adding activities across the organization.

Strategic Roles in Enhancing Business Performance

Operations strategy defines the long-term plan to configure resources and processes that align with business goals, focusing on cost leadership, quality, flexibility, and innovation. Value chain analysis decomposes a company's primary and support activities to identify competitive advantages and operational efficiencies that enhance customer value. Integrating strategic roles in operations and value chain management drives superior business performance by optimizing internal capabilities and delivering differentiated products or services.

Components of Effective Operations Strategy

Effective operations strategy integrates key components such as process design, capacity planning, supply chain management, and performance measurement to optimize resources and enhance productivity. Value chain analysis complements this strategy by identifying critical activities that create value, enabling organizations to focus on core competencies and cost efficiencies. Aligning operational capabilities with value chain activities ensures competitive advantage through improved quality, speed, and flexibility.

Value Chain Activities and Their Impact

Value chain activities encompass inbound logistics, operations, outbound logistics, marketing and sales, and service, each driving competitive advantage through optimized resource allocation and process efficiency. Effective management of these activities enhances value creation by reducing costs and differentiating products, directly impacting profitability and market positioning. Operations strategy aligns these value chain components with business goals, ensuring sustained performance and long-term growth.

Aligning Operations Strategy with Value Chain Optimization

Aligning operations strategy with value chain optimization enhances overall efficiency by integrating activities from suppliers to end customers, ensuring resources are used effectively. This alignment focuses on streamlining processes such as procurement, production, and distribution to reduce costs and improve product quality. Prioritizing strategic decisions that support value chain optimization drives competitive advantage and long-term business sustainability.

Case Studies Comparing Operations Strategy and Value Chain

Case studies comparing operations strategy and value chain reveal how companies optimize production processes and enhance competitive advantage by aligning operational capabilities with value creation activities. For example, Toyota's lean manufacturing exemplifies operations strategy focused on waste reduction while Amazon's value chain integration emphasizes seamless logistics and customer experience. These analyses demonstrate that integrating operations strategy with value chain insights drives efficiency, cost leadership, and differentiated value propositions.

Best Practices for Integrating Operations Strategy and Value Chain

Integrating operations strategy and the value chain requires aligning core processes such as procurement, production, and distribution with strategic business objectives to enhance efficiency and customer value. Best practices include leveraging data analytics for real-time process optimization, fostering cross-functional collaboration to break down silos, and implementing continuous improvement methodologies like Lean and Six Sigma. Prioritizing sustainability and technology adoption within both operations and the value chain further strengthens competitive advantage and drives long-term profitability.

Operations Strategy Infographic

libterm.com

libterm.com