Reliability Centered Maintenance (RCM) focuses on identifying and prioritizing maintenance tasks based on the criticality and failure modes of assets to maximize operational reliability. This approach helps you optimize maintenance resources, reduce downtime, and improve safety by targeting the most impactful maintenance activities. Explore the rest of the article to learn how RCM can transform your maintenance strategy.

Table of Comparison

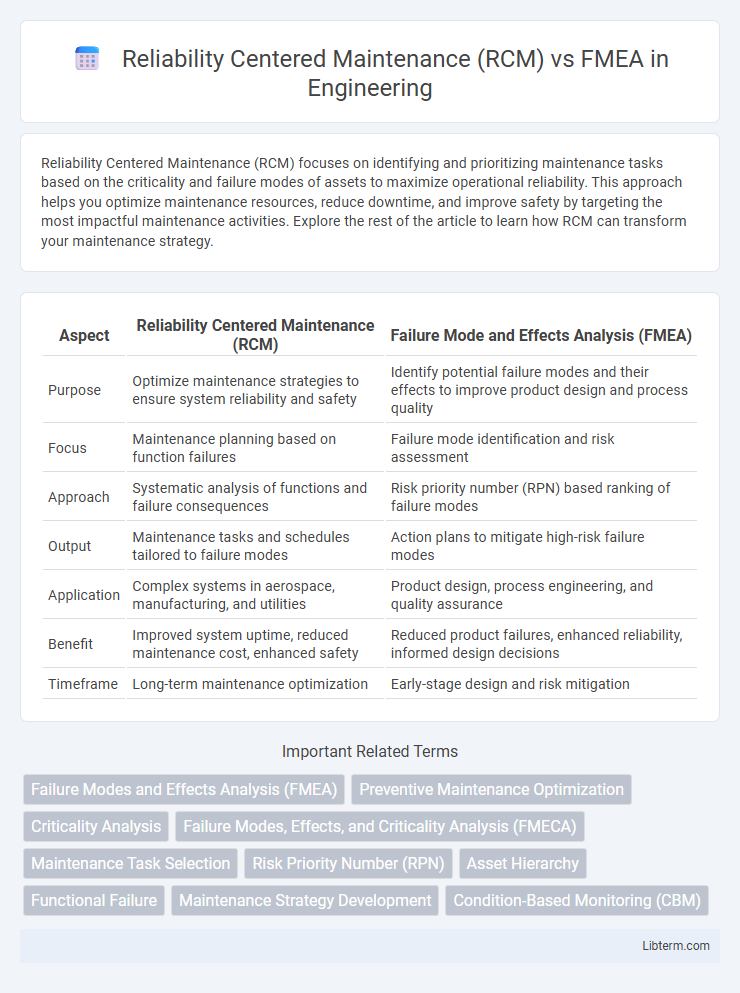

| Aspect | Reliability Centered Maintenance (RCM) | Failure Mode and Effects Analysis (FMEA) |

|---|---|---|

| Purpose | Optimize maintenance strategies to ensure system reliability and safety | Identify potential failure modes and their effects to improve product design and process quality |

| Focus | Maintenance planning based on function failures | Failure mode identification and risk assessment |

| Approach | Systematic analysis of functions and failure consequences | Risk priority number (RPN) based ranking of failure modes |

| Output | Maintenance tasks and schedules tailored to failure modes | Action plans to mitigate high-risk failure modes |

| Application | Complex systems in aerospace, manufacturing, and utilities | Product design, process engineering, and quality assurance |

| Benefit | Improved system uptime, reduced maintenance cost, enhanced safety | Reduced product failures, enhanced reliability, informed design decisions |

| Timeframe | Long-term maintenance optimization | Early-stage design and risk mitigation |

Introduction to Reliability Centered Maintenance (RCM)

Reliability Centered Maintenance (RCM) is a structured approach that prioritizes maintenance strategies based on the criticality of equipment functions and potential failure consequences to ensure optimal system reliability. Unlike FMEA, which systematically identifies potential failure modes and their effects, RCM integrates these analyses to develop maintenance plans that balance safety, operational efficiency, and cost. This methodology emphasizes proactive maintenance tasks such as predictive and preventive maintenance tailored to specific equipment functions and risk profiles.

Understanding Failure Modes and Effects Analysis (FMEA)

Failure Modes and Effects Analysis (FMEA) systematically identifies potential failure modes within a system and evaluates their effects to prioritize risk mitigation strategies. Unlike Reliability Centered Maintenance (RCM), which develops maintenance plans based on functional failures and operational context, FMEA focuses primarily on early detection and prevention by assessing failure severity, occurrence, and detection ratings. This analytical approach enhances reliability by addressing vulnerabilities before failures impact overall performance.

Core Principles: RCM vs. FMEA

Reliability Centered Maintenance (RCM) focuses on maintaining system functions by prioritizing failure consequences and selecting appropriate maintenance strategies to ensure operational reliability, whereas Failure Modes and Effects Analysis (FMEA) systematically identifies and evaluates potential failure modes to assess their impact and mitigate risks. RCM emphasizes preserving system functionality through risk-based maintenance tasks, while FMEA centers on early detection and prevention of failures by analyzing cause-effect relationships. Both methodologies complement each other but diverge in approach, with RCM being more maintenance-strategy driven and FMEA focusing on failure identification and risk assessment.

Scope and Application: Where Each Method Excels

Reliability Centered Maintenance (RCM) excels in optimizing maintenance strategies by focusing on asset criticality and operational context to ensure system reliability and safety, making it ideal for complex, safety-critical industries like aviation and nuclear power. Failure Modes and Effects Analysis (FMEA) provides a systematic approach to identify and prioritize potential failure modes at the component level, widely applied in design and manufacturing to prevent defects and enhance product quality. While RCM is best suited for maintenance decision-making and lifecycle management, FMEA is more effective in early-stage risk assessment and design validation.

Step-by-Step Processes Compared

Reliability Centered Maintenance (RCM) follows a structured process that begins with identifying asset functions, assessing failure modes, and determining maintenance tasks based on failure criticality and consequences. Failure Modes and Effects Analysis (FMEA) involves systematically listing potential failure modes, analyzing their effects, and prioritizing risks using Risk Priority Numbers (RPN) to guide mitigation strategies. Both methodologies emphasize failure analysis but RCM integrates maintenance task selection to optimize asset reliability, whereas FMEA focuses primarily on risk assessment and prevention.

Data Requirements and Analysis Techniques

Reliability Centered Maintenance (RCM) prioritizes the evaluation of functional failures and their consequences using detailed operational and failure data to optimize maintenance strategies. Failure Modes and Effects Analysis (FMEA) focuses on identifying potential failure modes, their causes, and effects with emphasis on qualitative and quantitative risk assessment, often requiring comprehensive design and process data. Both methodologies use structured analysis techniques, but RCM integrates real-world reliability data to tailor maintenance tasks, while FMEA relies on systematic cause-effect analysis for early detection and prevention of failures.

Benefits and Limitations of RCM

Reliability Centered Maintenance (RCM) prioritizes maintenance tasks based on risk and functional failure consequences, enhancing asset reliability and cost efficiency by focusing on critical systems. Its benefits include improved safety, optimized resource allocation, and extended equipment life, while its limitations involve the complexity of implementation and the need for extensive data and expert knowledge. Compared to Failure Modes and Effects Analysis (FMEA), which systematically identifies potential failure modes, RCM integrates these findings to develop a maintenance strategy aligned with operational priorities.

Advantages and Challenges of FMEA

FMEA offers a systematic approach to identifying potential failure modes and their effects, prioritizing risks based on severity, occurrence, and detection, which enhances proactive maintenance planning. Its advantages include early failure detection, improved safety, and cost reduction through preventive measures, yet challenges arise from its resource-intensive nature, dependence on accurate data, and potential for overlooking complex failure interactions. Despite these challenges, FMEA remains vital for risk management by fostering detailed failure analysis and facilitating maintenance decision-making.

Integrating RCM and FMEA for Optimal Maintenance

Integrating Reliability Centered Maintenance (RCM) and Failure Modes and Effects Analysis (FMEA) maximizes maintenance strategies by combining RCM's focus on critical equipment functions with FMEA's detailed failure mode identification and prioritization. This integration enhances risk assessment accuracy, enabling targeted preventive maintenance that minimizes downtime and reduces lifecycle costs. Leveraging both methodologies supports data-driven decisions, improves reliability, and ensures optimal asset performance in complex industrial operations.

Choosing the Right Method for Your Organization

Reliability Centered Maintenance (RCM) focuses on identifying maintenance strategies based on functions and failure consequences, making it ideal for organizations seeking to optimize asset reliability and prioritize critical equipment. Failure Mode and Effects Analysis (FMEA) systematically evaluates potential failure modes and their effects to enhance product design and process reliability, suiting organizations aiming for early risk identification and quality improvement. Selecting between RCM and FMEA depends on organizational goals, with RCM best for maintenance optimization in operations-heavy industries and FMEA preferred for risk management in design and manufacturing environments.

Reliability Centered Maintenance (RCM) Infographic

libterm.com

libterm.com