Deformable materials possess the unique ability to change shape under stress while returning to their original form once the force is removed, making them essential in numerous engineering and medical applications. Their flexibility and resilience enable innovations from soft robotics to impact-absorbing safety gear. Discover how deformable materials can transform your understanding and use of adaptable technologies in the rest of this article.

Table of Comparison

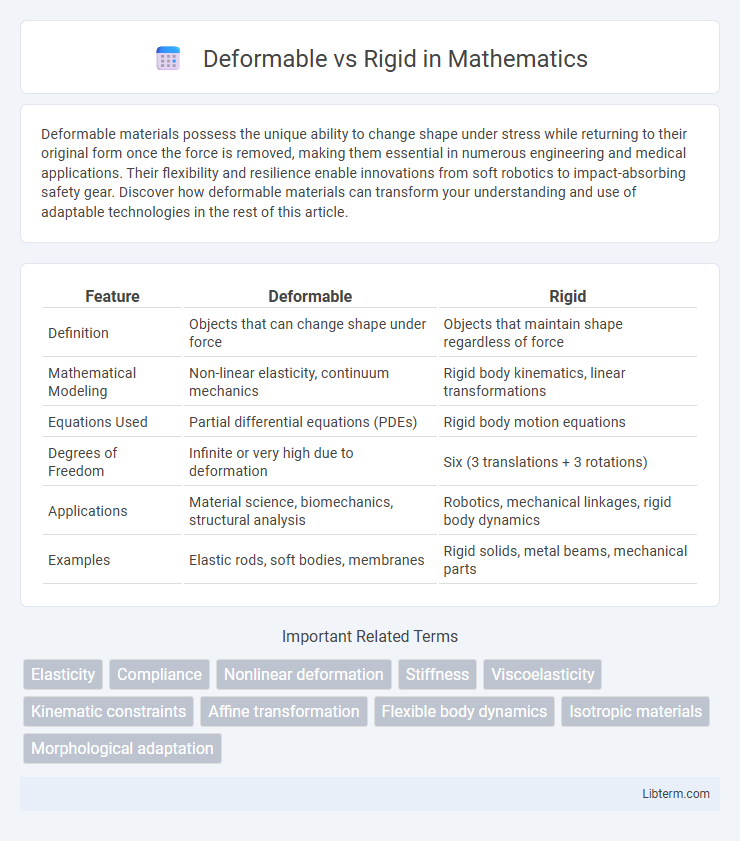

| Feature | Deformable | Rigid |

|---|---|---|

| Definition | Objects that can change shape under force | Objects that maintain shape regardless of force |

| Mathematical Modeling | Non-linear elasticity, continuum mechanics | Rigid body kinematics, linear transformations |

| Equations Used | Partial differential equations (PDEs) | Rigid body motion equations |

| Degrees of Freedom | Infinite or very high due to deformation | Six (3 translations + 3 rotations) |

| Applications | Material science, biomechanics, structural analysis | Robotics, mechanical linkages, rigid body dynamics |

| Examples | Elastic rods, soft bodies, membranes | Rigid solids, metal beams, mechanical parts |

Introduction to Deformable and Rigid Structures

Deformable structures are designed to undergo significant shape changes when subjected to external forces, allowing for flexibility and energy absorption in applications such as soft robotics and biomedical devices. Rigid structures maintain their shape and resist deformation under load, providing stability and strength in engineering frameworks like bridges and buildings. Understanding the fundamental differences between deformable and rigid structures is essential for optimizing material selection and structural design in various technological applications.

Defining Deformable and Rigid Materials

Deformable materials are characterized by their ability to undergo significant shape changes when subjected to forces, exhibiting elasticity, plasticity, or viscoelasticity depending on their molecular structure. Rigid materials, in contrast, resist deformation and maintain their shape under applied stress due to strong atomic or molecular bonds and a high modulus of elasticity. Understanding the mechanical properties such as Young's modulus, yield strength, and strain capacity is essential for differentiating deformable materials like polymers and metals from rigid materials like ceramics and glass.

Key Differences Between Deformable and Rigid Bodies

Deformable bodies experience shape changes when subjected to forces, characterized by elasticity and plasticity, whereas rigid bodies maintain constant shape and size regardless of applied forces. The key differences lie in deformation behavior, stress distribution, and energy absorption, with deformable bodies capable of storing strain energy and rigid bodies exhibiting negligible deformation. Analyzing these distinctions is critical in engineering applications such as material strength, structural analysis, and impact dynamics.

Applications of Rigid Materials

Rigid materials find extensive applications in construction, aerospace, and automotive industries due to their high strength, stability, and resistance to deformation under stress. They are essential in structural components such as beams, bridges, aircraft frames, and vehicle chassis, where maintaining shape and load-bearing capacity is critical. The ability of rigid materials like steel, aluminum, and composites to withstand harsh environmental conditions ensures safety and durability in engineering designs.

Applications of Deformable Materials

Deformable materials are widely used in biomedical applications such as soft tissue simulation and prosthetics, where flexibility and adaptability to movement are crucial. In robotics, these materials enable the development of soft robots that can navigate complex, unstructured environments by mimicking biological organisms. Furthermore, deformable materials play a key role in wearable technology, providing comfort and dynamic responsiveness for sensors and actuators integrated into clothing.

Mechanical Properties: Stress, Strain, and Deformation

Deformable materials exhibit significant strain and deformation under applied stress, characterized by their ability to undergo elastic or plastic changes without fracturing, whereas rigid materials resist deformation and maintain shape, showing minimal strain even at high stress levels. The mechanical properties of deformable substances often include a lower modulus of elasticity, allowing for energy absorption and flexibility, while rigid materials have a high modulus, resulting in brittleness and structural stability. Stress-strain curves for deformable materials typically display a distinct yield point and a larger region of plastic deformation, contrasting with rigid substances that exhibit linear elastic behavior up to fracture.

Advantages of Deformable Structures

Deformable structures offer significant advantages in applications requiring adaptability, shock absorption, and energy dissipation, enhancing safety and performance. Their ability to undergo controlled deformation allows for improved resilience under dynamic loads and impact conditions compared to rigid structures. This flexibility reduces material stress concentrations, extending the lifespan and reliability of components in aerospace, automotive, and civil engineering sectors.

Benefits of Rigid Bodies

Rigid bodies offer significant advantages in physics simulations and engineering applications due to their consistent shape and fixed volume, which simplify computational models and reduce processing time. Their stability ensures accurate collision detection and response, crucial for realistic animations and mechanical system analysis. Furthermore, rigid bodies require less memory and computational overhead compared to deformable models, making them ideal for real-time applications such as gaming and robotics.

Choosing Between Deformable and Rigid Solutions

Choosing between deformable and rigid solutions depends on the specific application requirements such as flexibility, durability, and load-bearing capacity. Deformable materials offer adaptability and energy absorption, making them ideal for impact resistance and comfort-focused designs, while rigid materials provide structural strength and stability essential for load-bearing and precision tasks. Evaluating factors like mechanical stress, environmental conditions, and long-term performance guides the optimal selection between deformable and rigid solutions.

Future Trends in Material Science: Deformable vs Rigid

Future trends in material science emphasize the development of hybrid materials that combine the adaptability of deformable substances with the strength of rigid structures, enhancing performance in aerospace and flexible electronics. Innovations in smart materials, such as shape-memory alloys and responsive polymers, enable devices that dynamically adjust their rigidity based on environmental stimuli. Advances in nanotechnology and additive manufacturing further facilitate precise control over material properties, paving the way for customizable, multifunctional materials with applications in healthcare, robotics, and wearable technology.

Deformable Infographic

libterm.com

libterm.com