Plastic is a versatile synthetic material widely used in packaging, construction, and everyday products due to its durability, lightweight nature, and cost-effectiveness. Understanding plastic types and their environmental impact is crucial for making informed choices about disposal and recycling. Explore the rest of the article to learn how you can reduce plastic waste and contribute to a sustainable future.

Table of Comparison

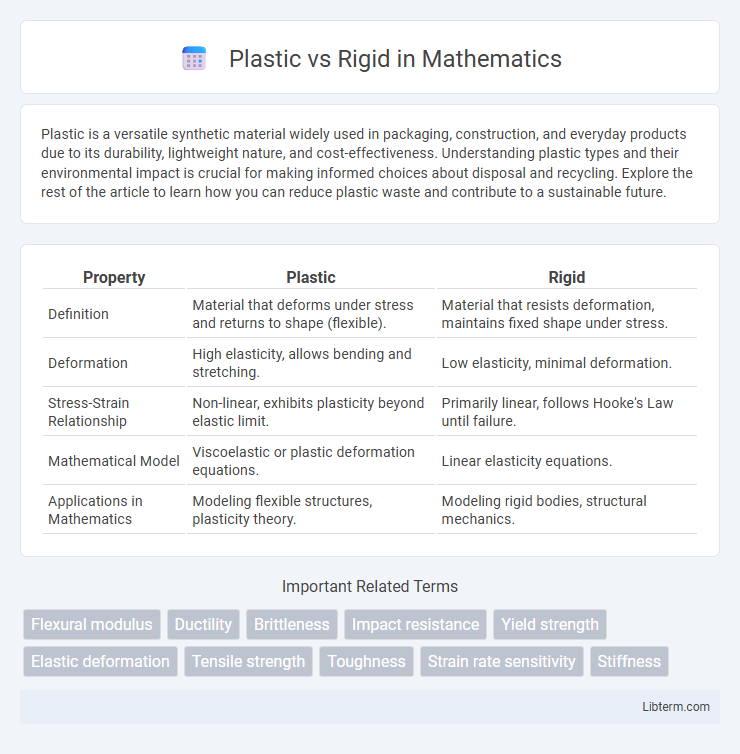

| Property | Plastic | Rigid |

|---|---|---|

| Definition | Material that deforms under stress and returns to shape (flexible). | Material that resists deformation, maintains fixed shape under stress. |

| Deformation | High elasticity, allows bending and stretching. | Low elasticity, minimal deformation. |

| Stress-Strain Relationship | Non-linear, exhibits plasticity beyond elastic limit. | Primarily linear, follows Hooke's Law until failure. |

| Mathematical Model | Viscoelastic or plastic deformation equations. | Linear elasticity equations. |

| Applications in Mathematics | Modeling flexible structures, plasticity theory. | Modeling rigid bodies, structural mechanics. |

Understanding Plastic and Rigid Materials

Plastic materials are composed of polymers that offer flexibility, lightweight properties, and resistance to impact, making them ideal for applications requiring durability and adaptability. Rigid materials, such as metals and certain plastics like thermosets, provide structural strength and stability but lack the flexibility of softer plastics. Understanding the specific molecular structure and mechanical properties of plastic and rigid materials is essential for selecting the appropriate material for industrial, construction, or consumer product uses.

Key Differences: Plastic vs Rigid

Plastic materials offer high flexibility and impact resistance, making them ideal for applications requiring bendable or lightweight components. Rigid materials provide superior structural strength, durability, and shape retention, essential for load-bearing and long-term use. Key differences lie in their mechanical properties, with plastic excelling in elasticity and rigidity dominating in stiffness and stability.

Common Applications of Plastic

Plastic materials are extensively used in packaging, automotive parts, consumer electronics, and medical devices due to their lightweight, flexibility, and cost-effectiveness. Common plastic types like polyethylene, polypropylene, and PVC provide durability and resistance to chemicals, making them ideal for containers, pipes, and insulation. These applications benefit from plastic's ability to be molded into complex shapes, enhancing design versatility and manufacturing efficiency.

Common Uses of Rigid Materials

Rigid materials are frequently used in construction for structural components such as beams, columns, and panels due to their high strength and durability. They are essential in manufacturing automotive parts where stability and resistance to deformation are critical for safety and performance. Additionally, rigid materials find common applications in packaging for protecting fragile items during shipping and storage, ensuring minimal damage.

Durability and Strength Comparison

Rigid materials generally offer superior durability and strength compared to most plastics, making them ideal for structural applications and heavy load-bearing uses. Plastics vary widely in strength and durability, with engineered types like polycarbonate or ABS providing considerable resistance to impact and wear, but often falling short of metals or composites in long-term toughness. Durability of plastics can be enhanced through additives and composite formulations, yet rigid materials maintain higher tensile strength and resistance to deformation under stress.

Environmental Impact: Plastic vs Rigid

Plastic's environmental impact is significant due to its long decomposition time, often taking hundreds of years to break down, leading to persistent pollution in landfills and oceans. Rigid materials, such as metal or glass, typically have higher recyclability rates and lower toxicity, reducing their ecological footprint compared to plastic. The production of plastic also contributes substantially to greenhouse gas emissions, while rigid alternatives often rely on more energy-intensive initial manufacturing but offer better sustainability over their lifecycle.

Cost Factors and Affordability

Plastic materials generally offer lower production costs due to cheaper raw materials and faster manufacturing processes compared to rigid alternatives. Rigid materials, such as metals or hard composites, often incur higher expenses related to durability, machining, and transportation weight. Affordability hinges on the application's performance requirements, with plastic favored for cost-sensitive projects and rigid materials chosen when structural strength justifies the premium.

Flexibility and Adaptability

Plastic materials exhibit superior flexibility due to their molecular structure, allowing them to bend and stretch without breaking, which enhances their adaptability in diverse applications such as packaging and wearable devices. Rigid materials, characterized by a fixed internal structure, offer limited flexibility but provide strength and stability, making them ideal for structural components and load-bearing uses. The choice between plastic and rigid materials depends largely on the need for dynamic movement versus structural integrity in product design.

Safety and Health Considerations

Rigid materials generally offer enhanced safety due to their structural stability, reducing the risk of breakage and sharp edges that can cause injuries. Plastic, while lightweight and flexible, may release harmful chemicals like BPA or phthalates, especially when exposed to heat, posing health risks over prolonged use. Selecting BPA-free and food-grade plastics mitigates some health concerns, but rigid materials often provide superior durability and safety in environments requiring impact resistance.

Choosing the Right Material for Your Needs

Choosing the right material between plastic and rigid options depends on factors such as durability, flexibility, cost, and application requirements. Plastic provides lightweight, versatile solutions ideal for products requiring flexibility and cost-efficiency, while rigid materials offer superior strength and structural stability for heavy-duty or load-bearing uses. Understanding the specific demands of your project ensures optimal performance and longevity by aligning material properties with functional needs.

Plastic Infographic

libterm.com

libterm.com